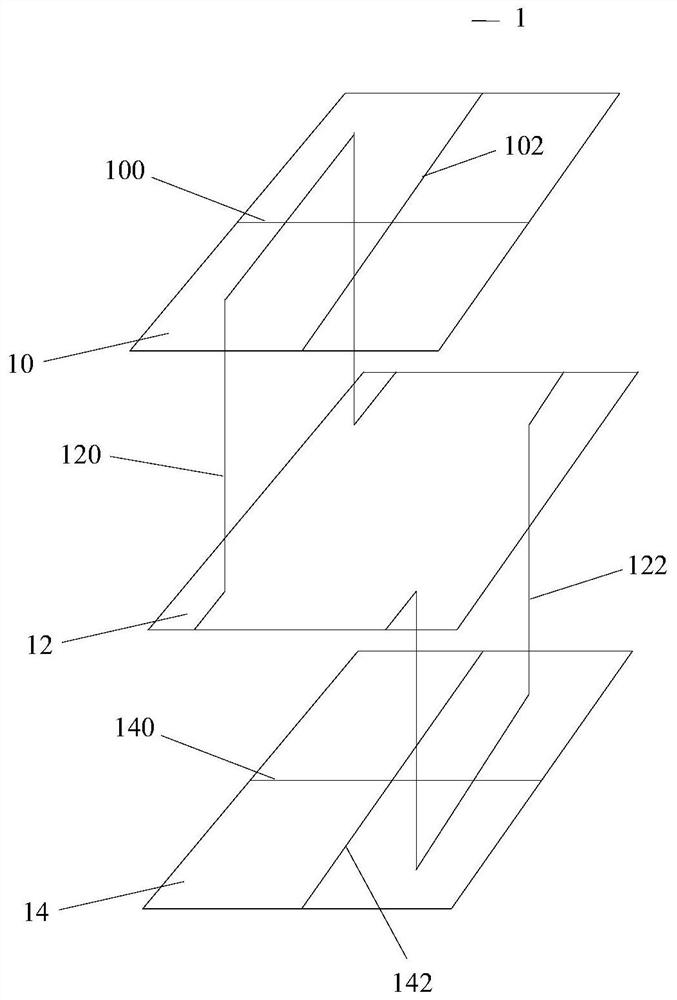

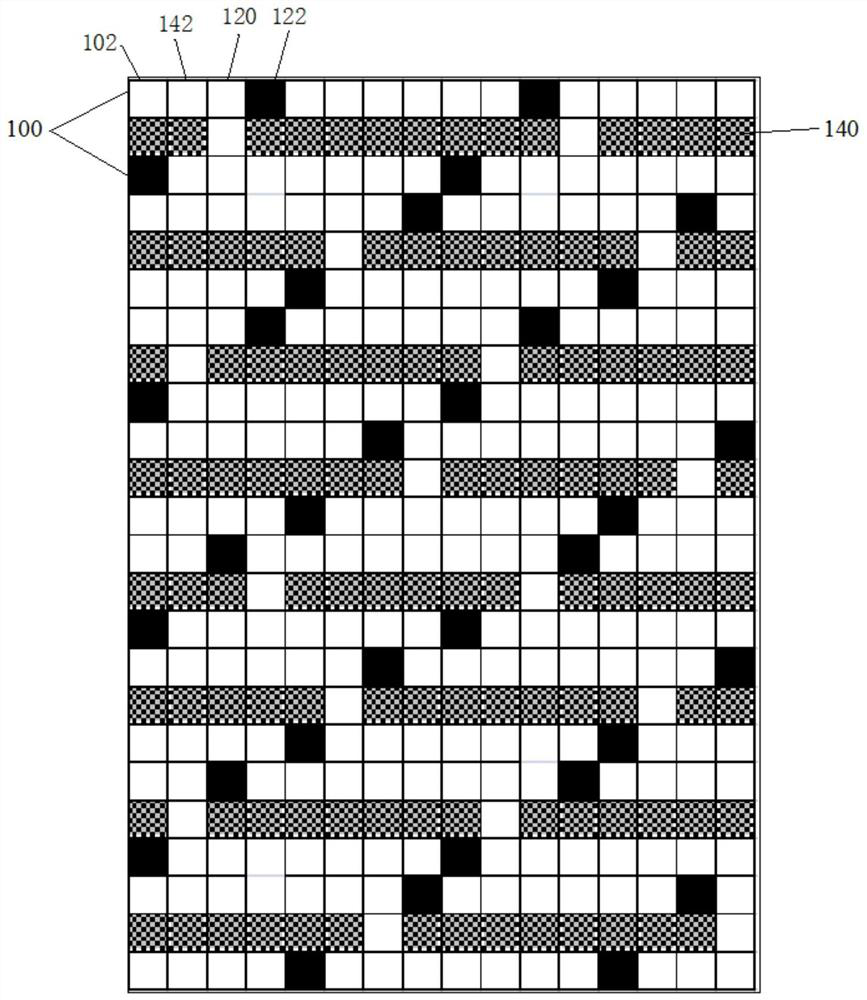

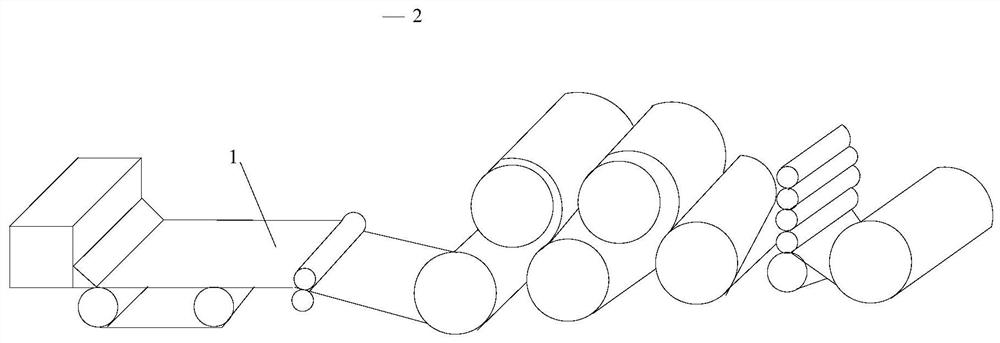

Novel warp sewing household paper three-layer forming net and papermaking equipment

A technology of household paper and forming net, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of slow dehydration, low fiber support index of paper layer, large diameter change of paper layer and machine layer, etc. Achieve the effect of increasing fiber support index, eliminating and delamination phenomenon, and uniform paper sheet formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The warp of the paper layer adopts polyester monofilament with a diameter of 0.13mm, the weft of the paper layer adopts polyester monofilament with a diameter of 0.13mm, the warp of the middle connecting layer adopts polyester monofilament with a diameter of 0.13mm, and the machine layer The warp of the machine layer is made of polyester monofilament with a diameter of 0.13mm, and the weft of the machine layer is made of polyester monofilament and nylon monofilament with a diameter of 0.20mm. The performance test of the papermaking forming wire for special paper in Example 1 was carried out by the method in ", and the test results are shown in Table 1 below.

Embodiment 2

[0034] The warp of the paper layer adopts polyester monofilament with a diameter of 0.13mm, the weft of the paper layer adopts polyester monofilament with a diameter of 0.13mm, the warp of the middle connecting layer adopts polyester monofilament with a diameter of 0.13mm, and the machine layer The warp of the machine layer is made of polyester monofilament with a diameter of 0.13mm, and the weft of the machine layer is made of polyester monofilament with a diameter of 0.25mm. The method in GB / T 24290-2009 "Measurement Method for Paper Forming Wire and Drying Wire" is used for implementation. The performance test of the special paper in Example 1 was carried out with a papermaking forming wire, and the test results are shown in Table 1 below.

[0035] Table 1: Performance testing results of the new warp-stitched tissue paper three-layer forming fabric

[0036] performance Example 1 result Example 2 result Warp density 76 pcs / cm 76 pcs / cm Weft densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap