Novel automatic overflowing type repairing ribbed filling block floor slab

A technology of filling blocks and dense ribs, applied in the direction of floor slabs, building maintenance, building components, etc., can solve problems such as cracking of the slab surface, difficulty in ensuring safety, and difficulty in internal self-repair, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

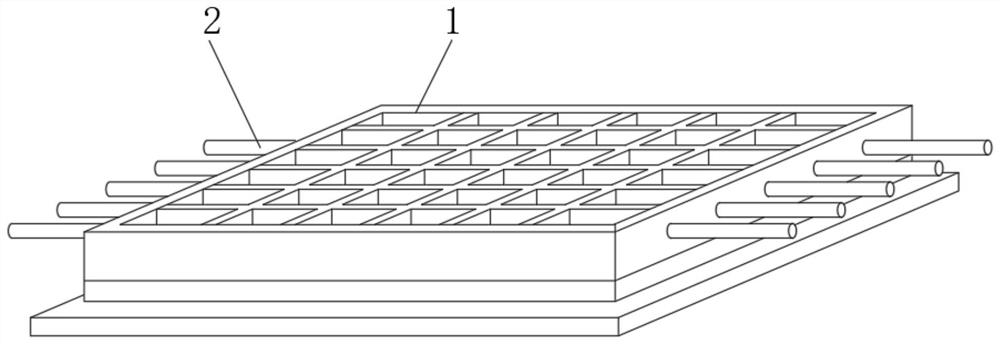

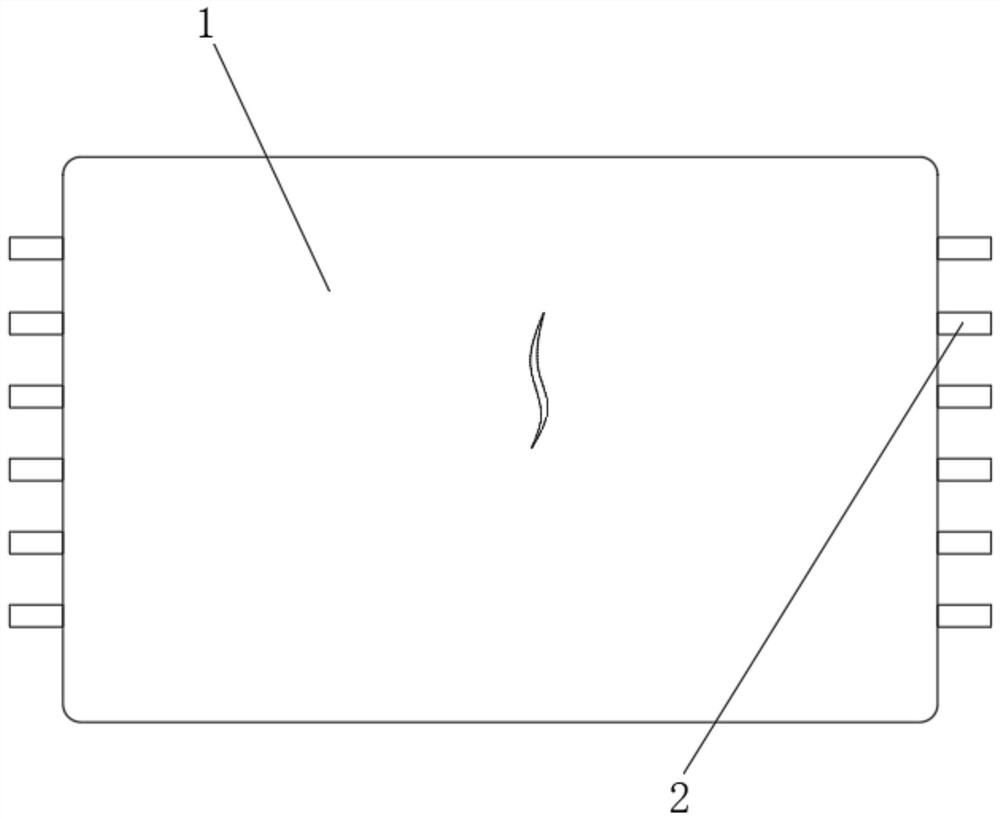

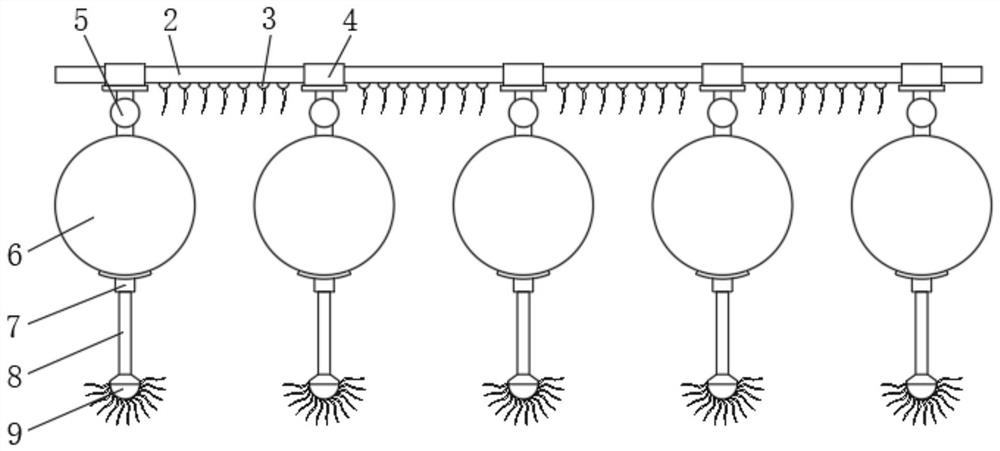

[0046] see Figure 1-9 , a new type of self-overflow repairing densely ribbed filling block floor, comprising a densely ribbed filling block floor body 1, capillary repairing tubes 2 are evenly distributed inside the densely ribbed filling block floor body 1, and the lower surface of the capillary repairing tube 2 is provided with reinforcement Fiber 3, the outer middle part of the capillary repair tube 2 is connected with a connector 4, the bottom of the connector 4 is provided with a release capsule 5, the lower side of the release capsule 5 is provided with a reaction ball 6, and the lower side of the reaction ball 6 is connected with a release shaft 7 The bottom of the release shaft 7 is connected to the oil storage shaft 8, the bottom of the oil storage shaft 8 is provided with a fastening fiber 9, the inside of the reaction ball 6 is provided with an elastic shaft 10, and the bottom of the elastic shaft 10 is fixedly installed with an adhesive block 11, A second water-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com