Adjustable supporting frame for building

A support frame and construction technology, which is applied in the directions of construction, building structure, and on-site preparation of building components, etc., can solve problems such as cylinder explosion of hydraulic telescopic mechanism, high installation density of support frame, and difficult access to the installation area of support frame, etc. Achieve the effect of increasing the installation density, improving the support effect, and reducing the incidence of accidents such as cylinder explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

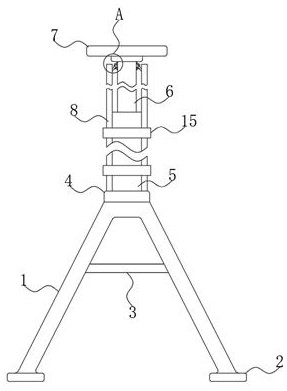

[0017] Example 1 as figure 1 As shown, an adjustable support frame for construction includes a support frame 1, and the bottom end of the support frame 1 is fixedly equipped with an anti-slip pad 2, and the number of anti-slip pads 2 is two groups. The anti-skid ability, the top outer surface of the support frame 1 is fixedly installed with the first fixed seat 4, the top outer surface of the first fixed seat 4 is fixedly installed with the hydraulic rod 5, and the structure of the hydraulic rod 5 is provided with a piston rod 6, the piston rod The top of 6 is fixedly installed with a second fixed seat 9, and the top outer surface of the second fixed seat 9 is fixedly equipped with a support plate 7, and the hydraulic telescopic mechanism formed by the combination of the hydraulic rod 5 and the piston rod 6 is controlled to lift, and the piston rod 6 moves upwards. And promote the second fixed seat 9 and the support plate 7 until the support plate 7 fits the formwork, thereby ...

Embodiment 2

[0018] Embodiment 2 is on the basis of embodiment 1, as figure 1 As shown, the support frame 1 is composed of a first inclined part and a second inclined part, and a reinforcing cross bar 3 is installed between the first inclined part and the second inclined part through bolts, and the reinforcing cross bar 3 can improve the structure of the supporting frame 1 The stability is good for use.

Embodiment 3

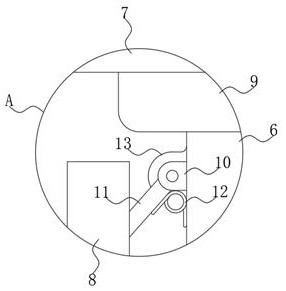

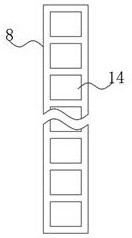

[0019] Embodiment 3 is on the basis of embodiment 1, as figure 2 and image 3 As shown, the top outer surface of the first fixed seat 4 is provided with an auxiliary rod 8, and one side outer surface of the auxiliary rod 8 is provided with a slot 14, and the outer wall of the piston rod 6 is fixedly installed with a mounting table 10, and in the structure of the mounting table 10 The insertion rod 11 is hingedly installed, and the combination of this structure enables the insertion rod 11 to perform a circular movement with the installation platform 10 as the center point, and the insertion rod 11 can cooperate with other components to achieve the desired effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com