Vibration damping device, compressor and water chilling unit

A vibration damping device, a technology for chillers, applied in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve problems such as poor vibration damping effect, and achieve the effect of improving vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

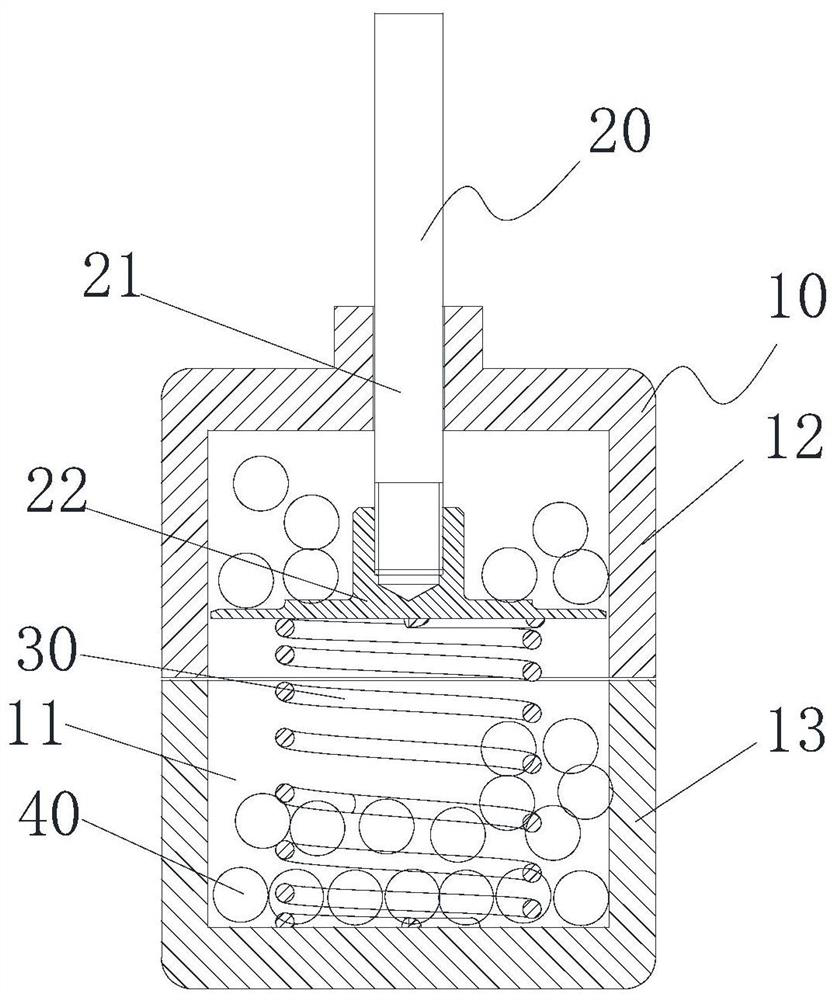

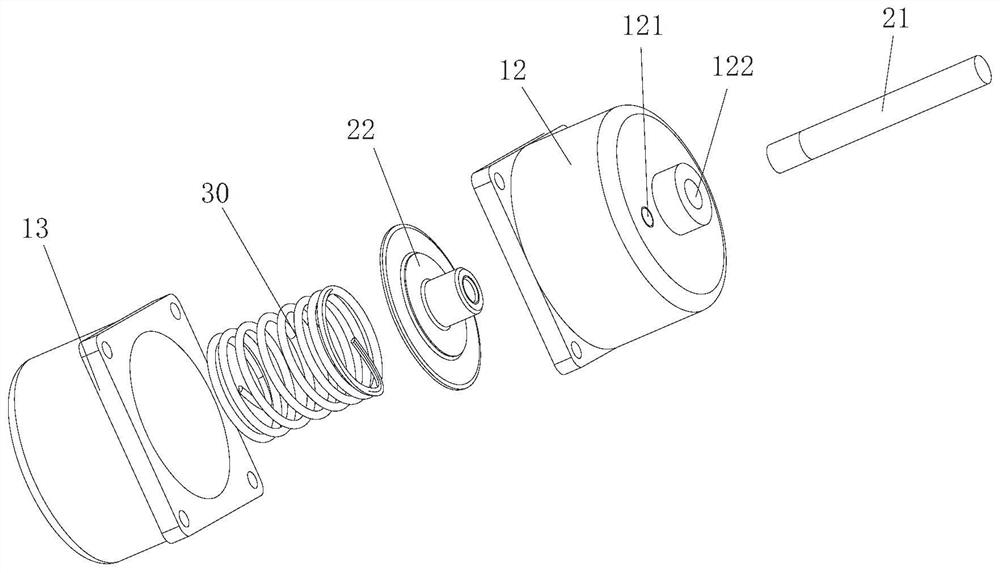

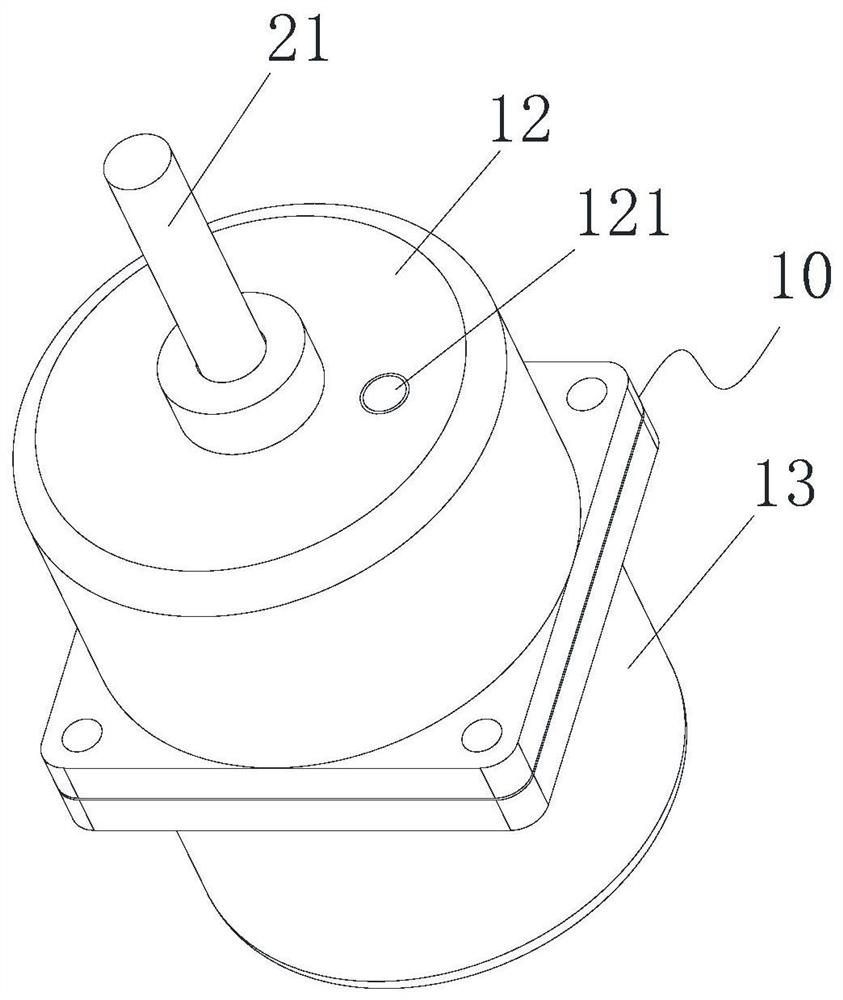

[0022] Such as figure 1 As shown, the present invention discloses a vibration damping device, including a housing 10, a connecting piece 20, a damping spring 30 and damping particles 40, the housing 10 has a damping cavity 11; the connecting piece 20 is passed through the housing 10 , the connecting piece 20 has a connecting end and a damping end, the connecting end of the connecting piece 20 is located outside the damping chamber 11 for connecting with the vibration source, the damping end of the connecting piece 20 is located in the damping chamber 11; the damping spring 30 Installed in the damping chamber 11, the first end of the damping spring 30 is connected to the connection end of the connector 20, and the second end of the damping spring 30 is connected to the inner wall of the housing 10; damping particles 40 are filled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com