Compressor, blade, two-dimensional blade profile design method of blade and computer equipment

A design method and axial flow compressor technology, applied in mechanical equipment, machine/engine, design optimization/simulation, etc., can solve problems such as changes and adjustment parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

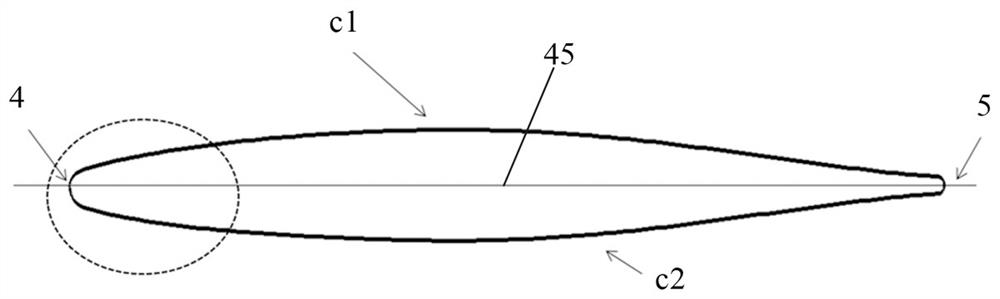

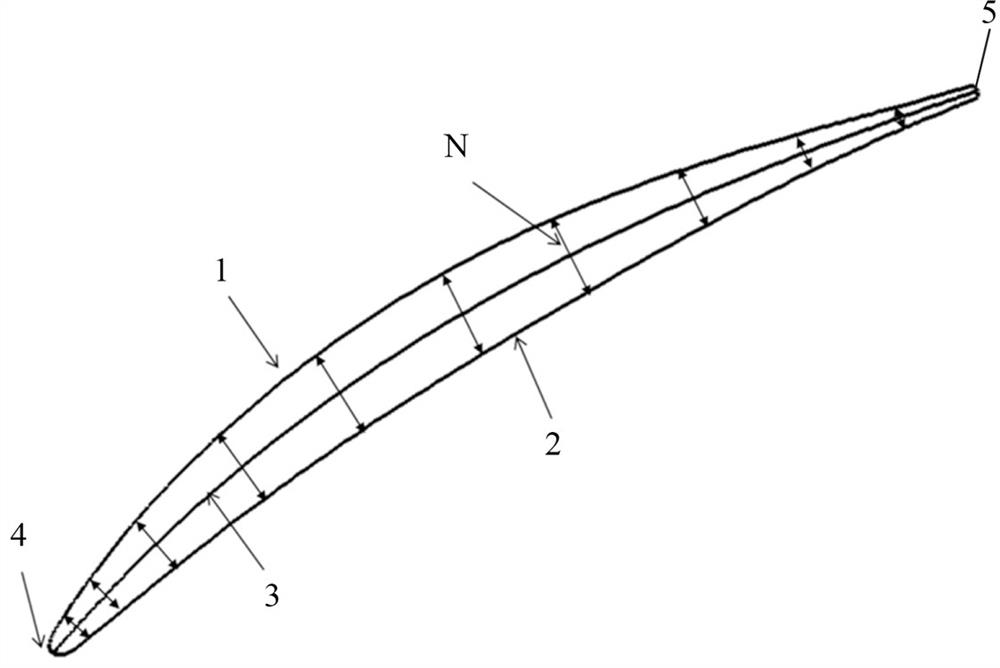

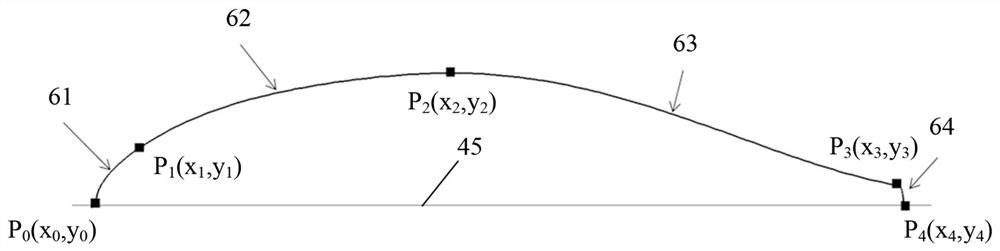

[0032] figure 1 Airfoil thickness distribution is shown. figure 2 A two-dimensional airfoil is shown. like figure 2 As shown, the airfoil surface consists of suction side 1 and pressure side 2. Superimposed along the normal direction N of the middle arc 3 as figure 1 The thickness curve c1 of the suction surface and the thickness curve c2 of the pressure surface are shown to generate the suction surface 1 and the pressure surface 2. The point where the suction surface 1 and the pressure surface 2 intersect on the front side is the leading edge 4, and the point where the suction surface intersects on the rear side is the rear edge. Edge 5, the process of superposition can be understood as the process of coordinate transformation. figure 1 The thickness shown is distributed along the direction of chord 45, the chord length of this chord 45 is equal to figure 2 The length of the middle arc 3 in . The thickness curve c1 of the suction surface and the thickness curve c2 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com