ATF oil-resistant, hydrolysis-resistant insulating layer, magnet wire and preparation method

A hydrolysis-resistant and insulating layer technology, used in insulated cables, insulators, insulated conductors, etc., can solve the problems of expensive imported magnet wires, affecting the reliability of oil-cooled motors, and inability to directly cool heat sources, achieving excellent mechanical properties, excellent The effect of hydrolysis resistance and excellent electrothermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] ATF oil-resistant, hydrolysis-resistant electromagnetic wire and a preparation method thereof, comprising the following steps:

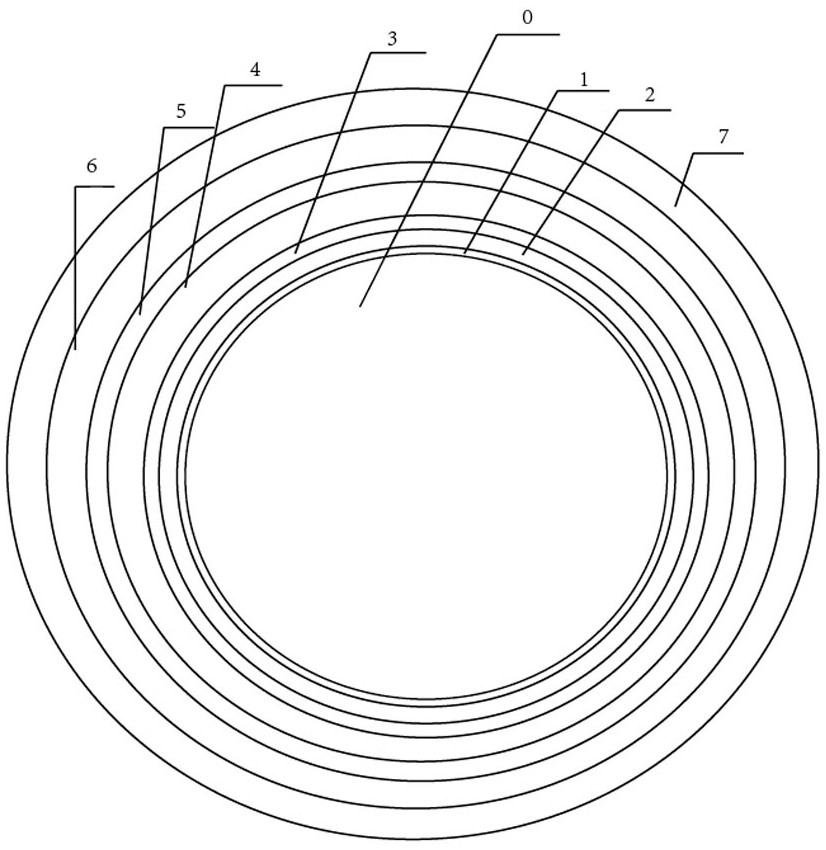

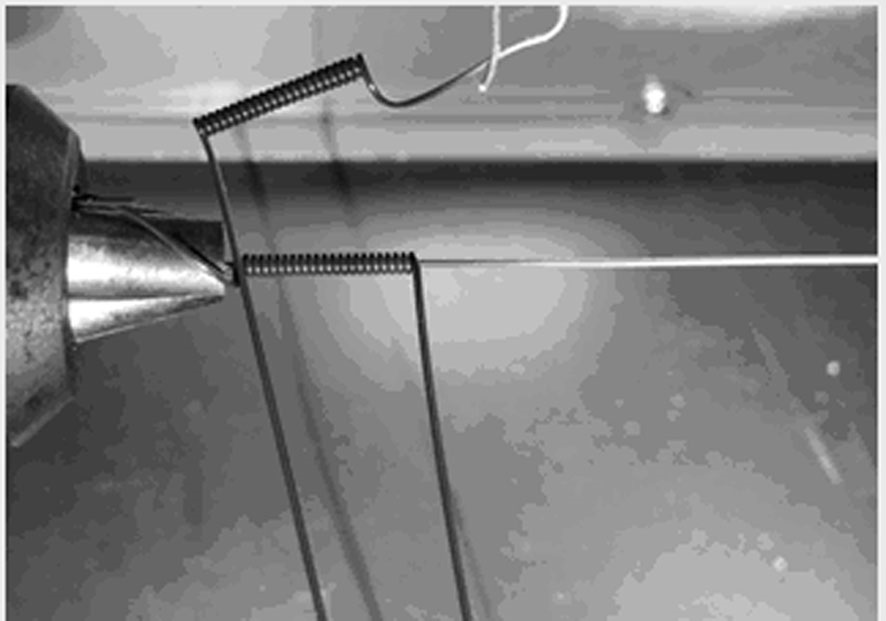

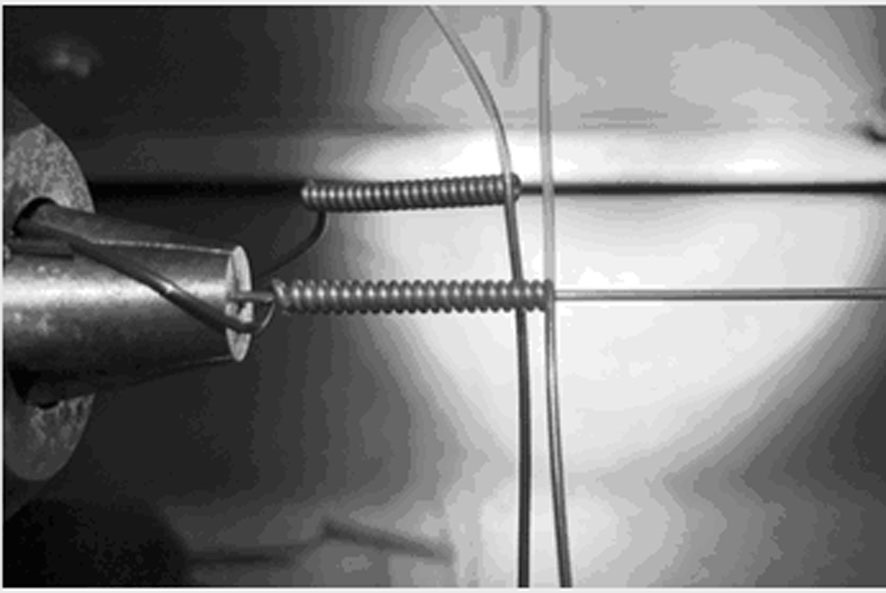

[0030]A coating mold made of cemented carbide (WC+Co) is used to coat polyimide paint on the outer surface of the annealed copper conductor, and the first polyimide layer is formed after drying and curing; and then coated with nano-inorganic fillers The polyamide-imide paint is dried and cured to form the second polyamide-imide layer; then coated with polyimide paint, dried and cured to form the third polyimide layer; then coated with nano-inorganic Filler polyamide-imide paint, drying and curing to form the fourth polyamide-imide layer; then coating polyimide paint, drying and curing to form the fifth polyimide layer; coating containing nano The polyamide-imide paint with inorganic filler forms the sixth polyamide-imide layer after drying and curing; then coats the polyimide paint, forms the seventh polyimide layer after drying and curing; co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com