Electromagnetic wire for new energy automobile driving motor and preparation method thereof

A technology for new energy vehicles and drive motors, applied in circuits, insulated cables, electrical components, etc., can solve problems such as poor voltage breakdown resistance, limited space utilization, and insufficient resin filling, and achieve ultra-high voltage shock resistance Wear performance, excellent mechanical properties, excellent abrasion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

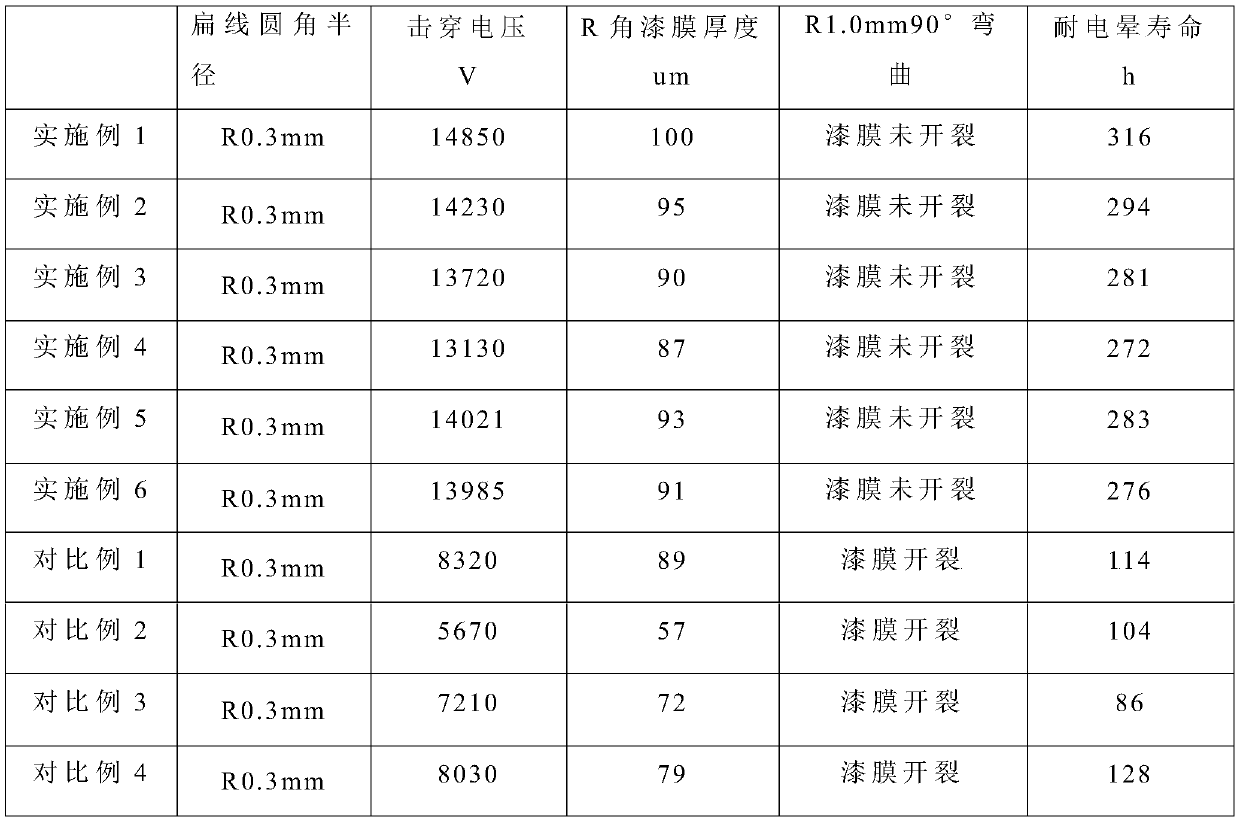

Examples

Embodiment 1

[0025] A method for preparing an electromagnetic wire for a drive motor of a new energy vehicle comprises the following steps:

[0026] (1) The round copper rod with a copper content ≥ 99.95% is drawn or finished rolled to obtain a flat copper wire. The drawing die for drawing is an imported polycrystalline wire drawing die. The conductor surface of the copper flat wire must be smooth without surface damage, Large-area oxidation, defects visible to the naked eye, resistivity of copper flat wire ≤0.01707Ω·mm 2 / m, elongation ≥ 40%; after the flat wire is unwound, enter the annealing furnace for annealing and softening, and control the annealing temperature to 570°C;

[0027] (2) A coating mold made of hard alloy (WC+Co) is used to coat the outer surface of the annealed flat wire with 3 layers of polyimide paint, and after drying and curing, the first polyimide paint with a thickness of 15 μm is formed. Amine layer, the solid content of the polyimide paint (Liujing Chemical Co....

Embodiment 2

[0031] It is basically the same as Example 1, except that the polyimide paint forming the first polyimide layer has a viscosity of 16 Pa.s at 30°C, and the polyimide paint forming the second polyimide layer The viscosity is 8Pa.s at 30°C.

Embodiment 3

[0033] It is basically the same as Example 1, except that the polyimide paint forming the first polyimide layer has a viscosity of 14 Pa.s at 30°C, and the polyimide paint forming the second polyimide layer The viscosity is 6Pa.s at 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com