Automatic flying bar assembly assembling machine and assembling method thereof

An assembly machine and flying rod technology, applied in electrical components, waveguide devices, circuits, etc., can solve the problems of low production efficiency and high labor costs, and achieve the effects of reducing labor costs, high automation, and simple and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

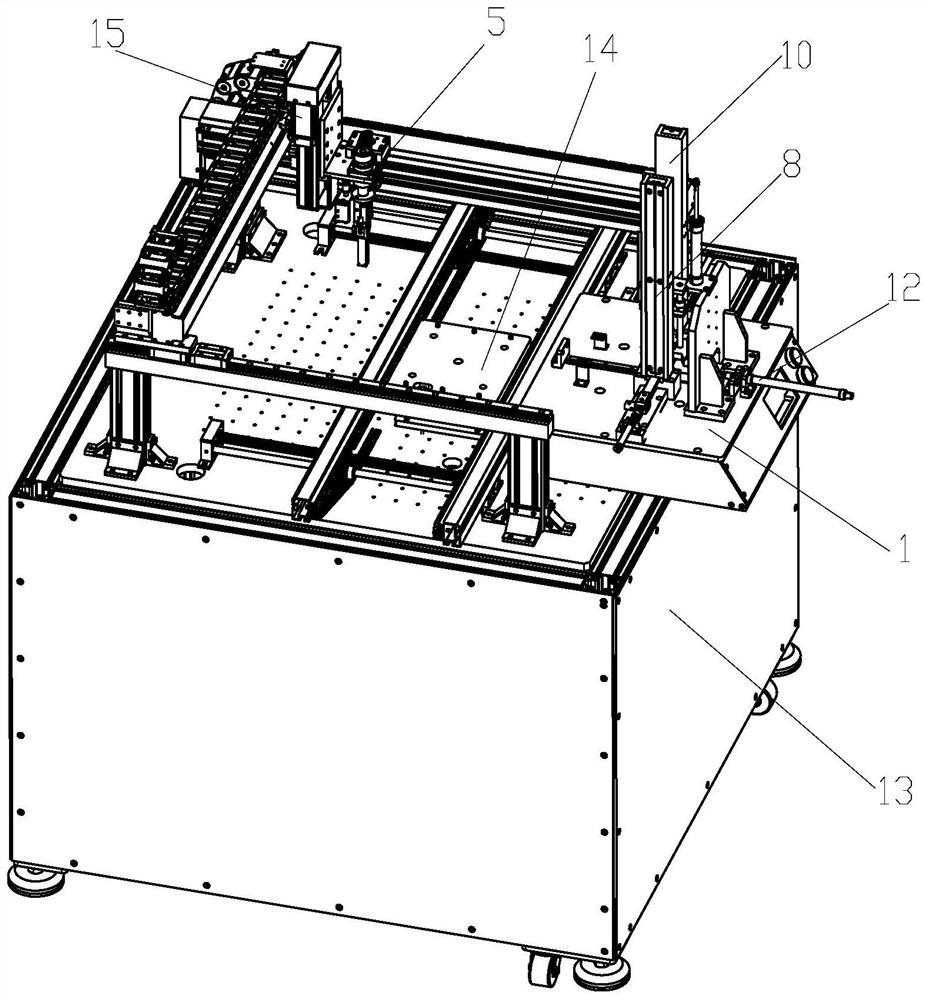

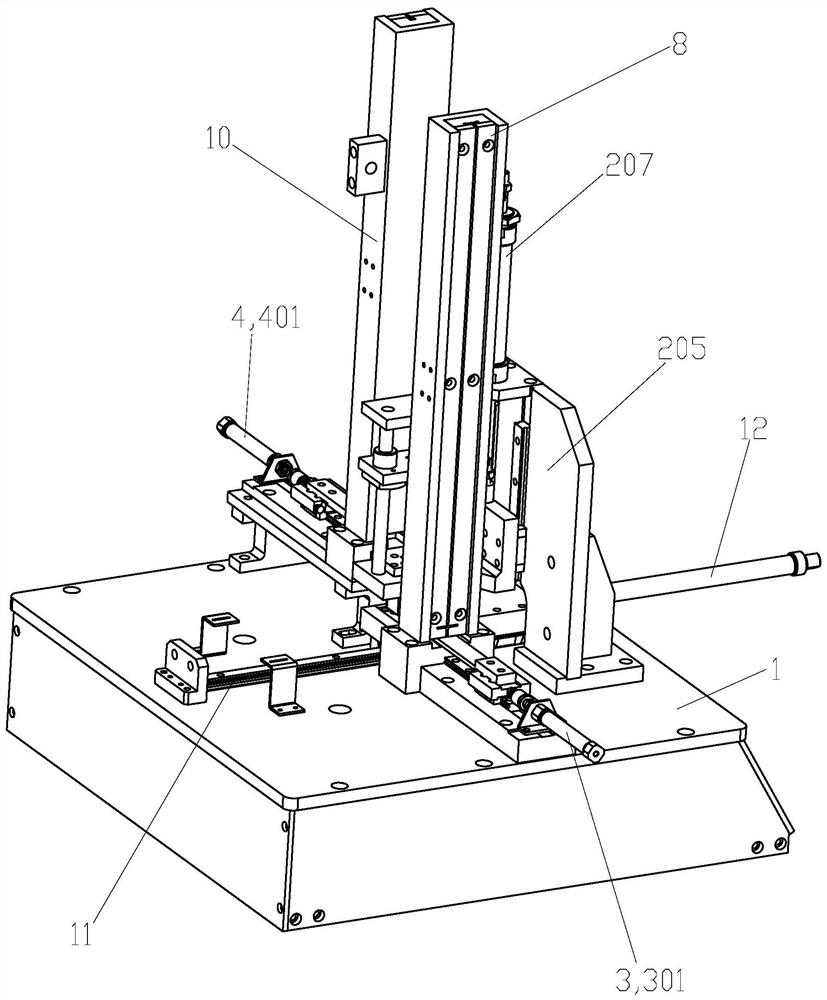

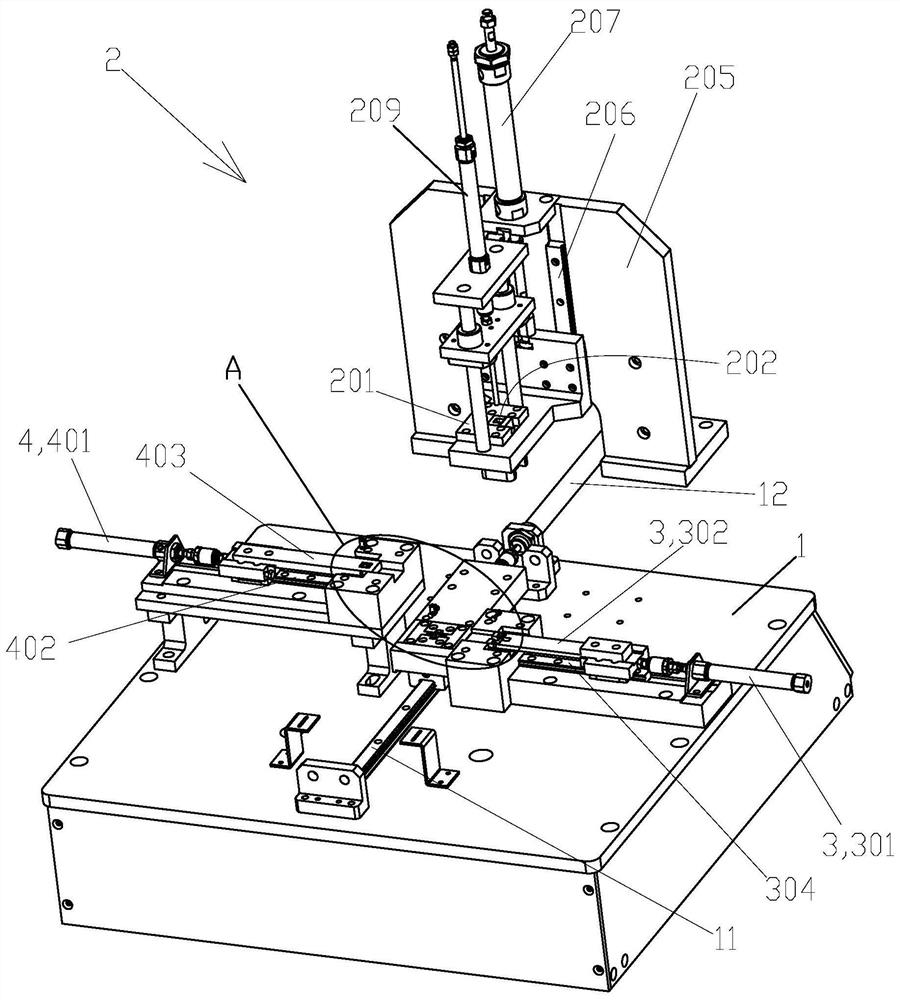

[0036] An automatic assembly machine for fly rod components, such as Figure 1 to Figure 9As shown, a mounting table 1 is included, and a first vertical track 8 for feeding the flying rod 6, a second vertical rail 10 for feeding the flying rod seat 7, and a A fourth slide rail 11 is respectively provided between the first vertical rail 8 and the second vertical rail 10, a first slide plate 9 is slidably provided on the fourth slide rail 11, and an assembly assembly is arranged on the first slide rail 9. The hole 901 is provided with the first pushing device 3 passing through the bottom of the first vertical rail 8 and pushing the flying rod 6 dropped on the first vertical rail 8 to the assembly hole 901 on the mounting table 1, the flying rod 6 falls from the first pushing device 3 to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap