A kind of processing equipment of mandrel of nasal surgery cutter

A technology of processing equipment and cutter, applied in metal processing equipment, metal processing, turning equipment and other directions, can solve the problems of cumbersome steps and low production efficiency, and achieve the effect of improving production efficiency, high production efficiency and high matching degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

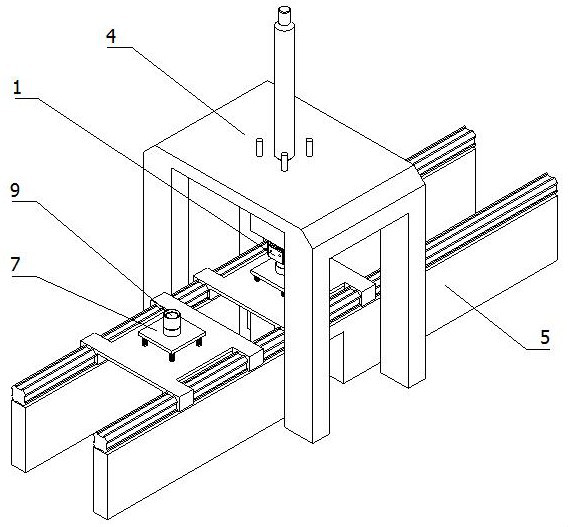

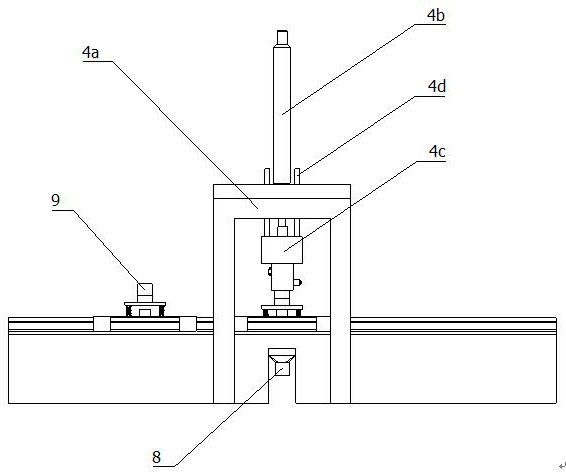

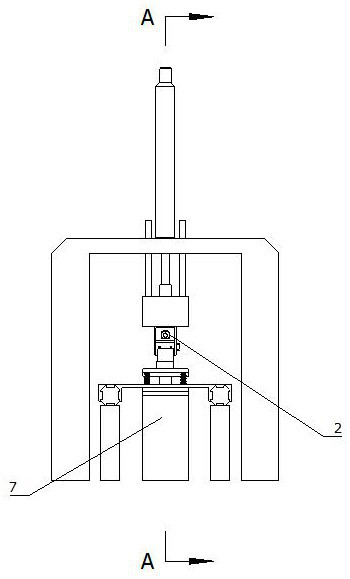

[0086] Such as Figure 1 to Figure 3 and Figure 12 As shown, a processing equipment for the mandrel of a nasal cavity surgery cutter is used to simultaneously cut out a matching groove for accommodating steel balls on the fixed knife seat 9a and ferrule 9b of the workpiece 9, including a pressing block 1, a movable knife rest 2. Cutting mechanism 3, lifting mechanism 4, linear transmission mechanism 5, elastic tooling 6, support frame 7 and debris cleaning mechanism 8;

[0087] The pressing block 1 is fixedly installed at the bottom of the working end of the lifting mechanism 4, and is used to press against the upper end of the fixed knife seat 9a and the ferrule 9b;

[0088] The movable tool rest 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com