New energy automobile charging pile with double charging guns

A technology for new energy vehicles and charging piles, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of shortening the service life of charging guns and affecting the charging of new energy vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

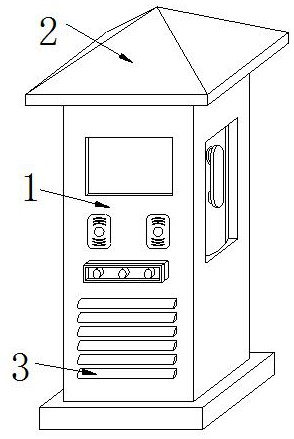

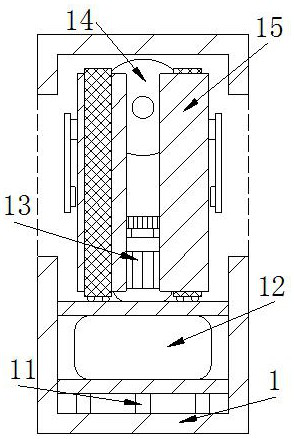

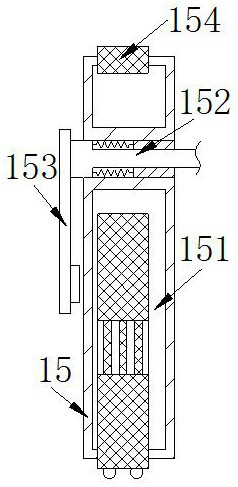

[0029] The present invention provides a charging pile for new energy vehicles with double charging guns. Its structure includes a charging pile 1, a ceiling 2, and a heat dissipation port 3. Located on the front side of the charging pile 1, the charging pile 1 includes a support plate 11, a storage box 12, a driver 13, a wire take-up 14, and a fixing block 15, and the support plate 11 is connected to the inner bottom of the charging pile 1 by welding, The battery box 12 is embedded on the upper surface of the support plate 11, the driver 13 is connected to the battery box 12, the wire take-up device 14 is connected to the inside of the charging pile 1 by bolts and is located above the driver 13, the fixed The block 15 is embedded and fixed on the left and right sides of the interior of the charging pile 1. The fixed block 15 is viewed as two symmetrical arc-shaped blocks, and the left and right sides of the charging pile 1 are provided with openings, and there are two wire take...

Embodiment 2

[0035]The present invention provides a charging pile for new energy vehicles with double charging guns. Its structure includes a charging pile 1, a ceiling 2, and a heat dissipation port 3. Located on the front side of the charging pile 1, the charging pile 1 includes a support plate 11, a storage box 12, a driver 13, a wire take-up 14, and a fixing block 15, and the support plate 11 is connected to the inner bottom of the charging pile 1 by welding, The battery box 12 is embedded on the upper surface of the support plate 11, the driver 13 is connected to the battery box 12, the wire take-up device 14 is connected to the inside of the charging pile 1 by bolts and is located above the driver 13, the fixed The block 15 is embedded and fixed on the left and right sides of the interior of the charging pile 1. The fixed block 15 is viewed as two symmetrical arc-shaped blocks, and the left and right sides of the charging pile 1 are provided with openings, and there are two wire take-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com