Clothes processing equipment

A technology for clothes processing equipment and housings, which is applied in household clothes dryers, textiles, papermaking, washing devices, etc., which can solve the problems of unsuitable air duct bases, poor versatility, and inability to produce molds, etc. Good vibration performance and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

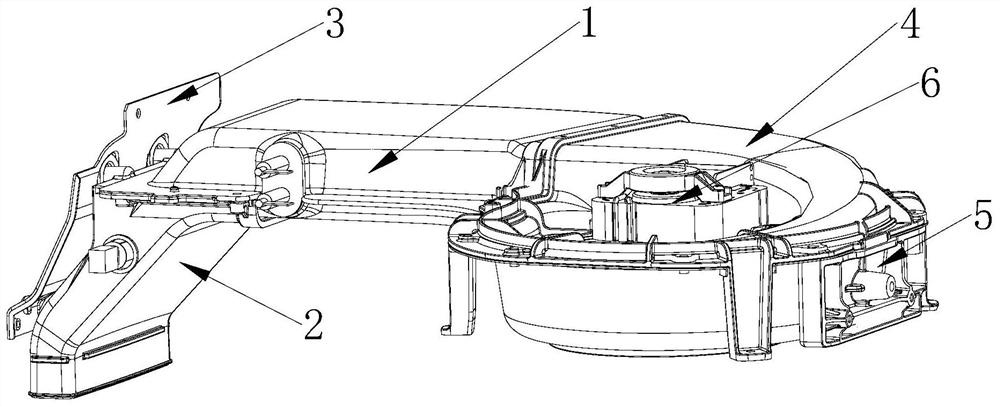

[0080] In this embodiment, the drying air duct 1 includes a first casing 11 and a second casing 12 connected to each other to form a fluid passage, and the fan fixing base 4 is connected to the first casing 11 and the second casing 12. The casings 12 are all connected, and the second transition structure 5 is connected to the fan fixing base 4 , the second casing 12 and / or the first casing 11 . In this application, due to the installation of the fan fixing base 4 and the second transfer structure 5, the first housing 11 and the second housing 12 are suitable for cast aluminum parts, injection molded parts, and sheet metal parts at the same time. better. Preferably, the first casing 11 is arranged above the second casing 12, and the fan fixing seat 4 is arranged above the second casing 12 and docked with the first casing 11, The second transition structure 5 is connected with the fan fixing base 4 and the second casing 12 .

[0081] A specific embodiment is that the second tr...

Embodiment 2

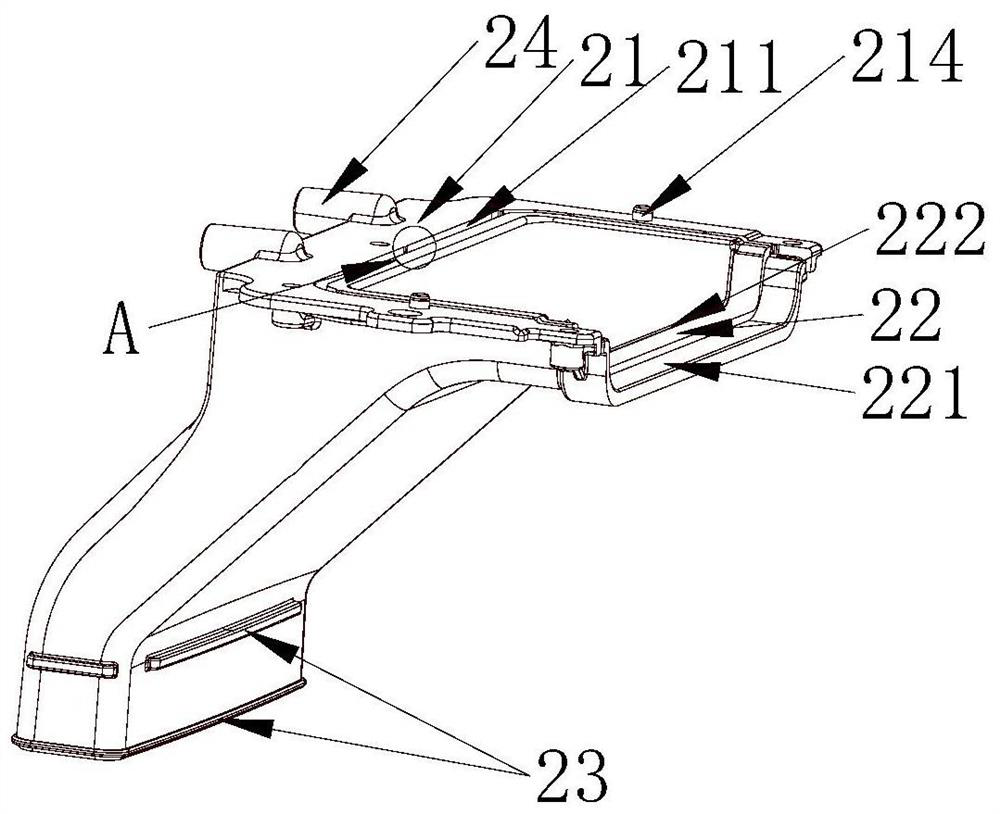

[0087] In this embodiment, the drying device further includes a first transfer structure, the drying air duct 1 and the cylinder communicate through the first transfer structure, and the first transfer structure is a section connecting the ventilation road. The drying air duct 1 is connected to the box body through the first transfer structure. Since the anti-vibration performance of the box body is better than that of the cylinder body, the fixing of the drying device is more reliable, and it is not easy to loosen, reducing the vibration noise. Due to the limitation of the internal space of the clothes processing equipment, the drying air duct 1 cannot be arranged at the front of the cylinder. Generally, the drying air duct 1 is provided with a bend at the front of the cylinder to guide hot air from the front of the cylinder. Inside the barrel, but because this part of the bend is provided, the drying air duct 1 cannot be applied to sheet metal forming, and its versatility i...

Embodiment 3

[0096] In this embodiment, the drying device further includes a sealing structure, the sealing structure is arranged between the adapter 2 and the drying air duct 1, and the adapter 2 is connected to the drying air duct 1 through the sealing structure. The dry air duct 1 is sealed and connected, the sealing structure is arranged between the fan fixing base 4 and the drying air duct 1, and the fan fixing base 4 is sealed with the drying air duct 1 through the sealing structure Connection, to prevent gas leakage, destroy the structure inside the box, or prevent gas leakage from being poured into the cylinder normally, and the drying effect is poor.

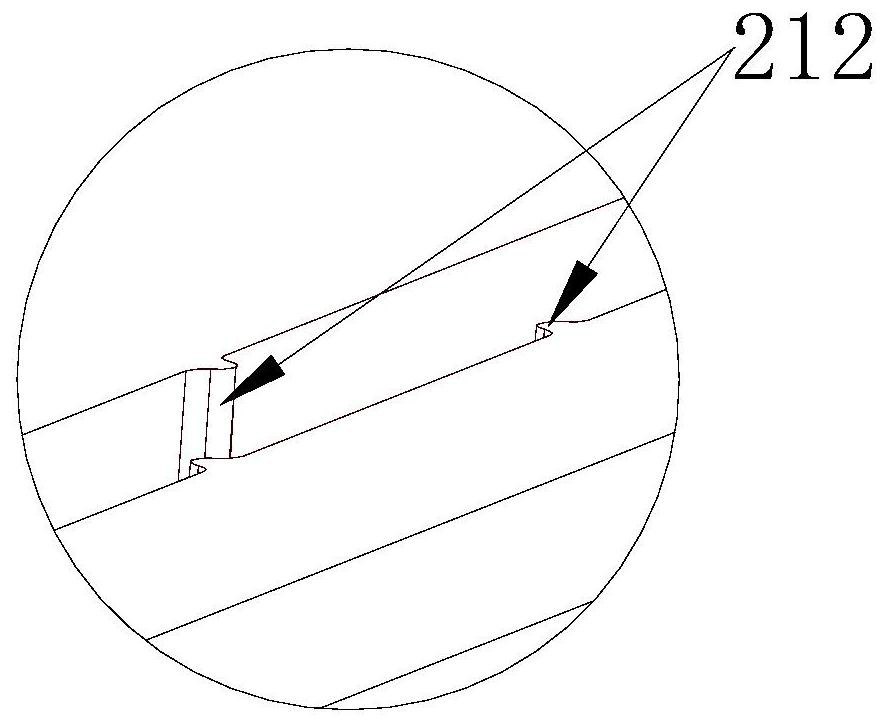

[0097] The sealing structure includes a first sealing part and a second sealing part, the first sealing part is arranged between the first transfer part 21 and the first housing 11, and the first transfer part 21 Sealed connection with the first casing 11, the second sealing part is arranged between the second transfer part 22 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com