A kind of subway tunnel system and construction method for vibration reduction and noise reduction

A technology for tunnels and subways, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of increased rail deformation, small vibration isolation effect, and high cost, and achieve the effect of improving efficiency, improving vibration reduction effect, and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

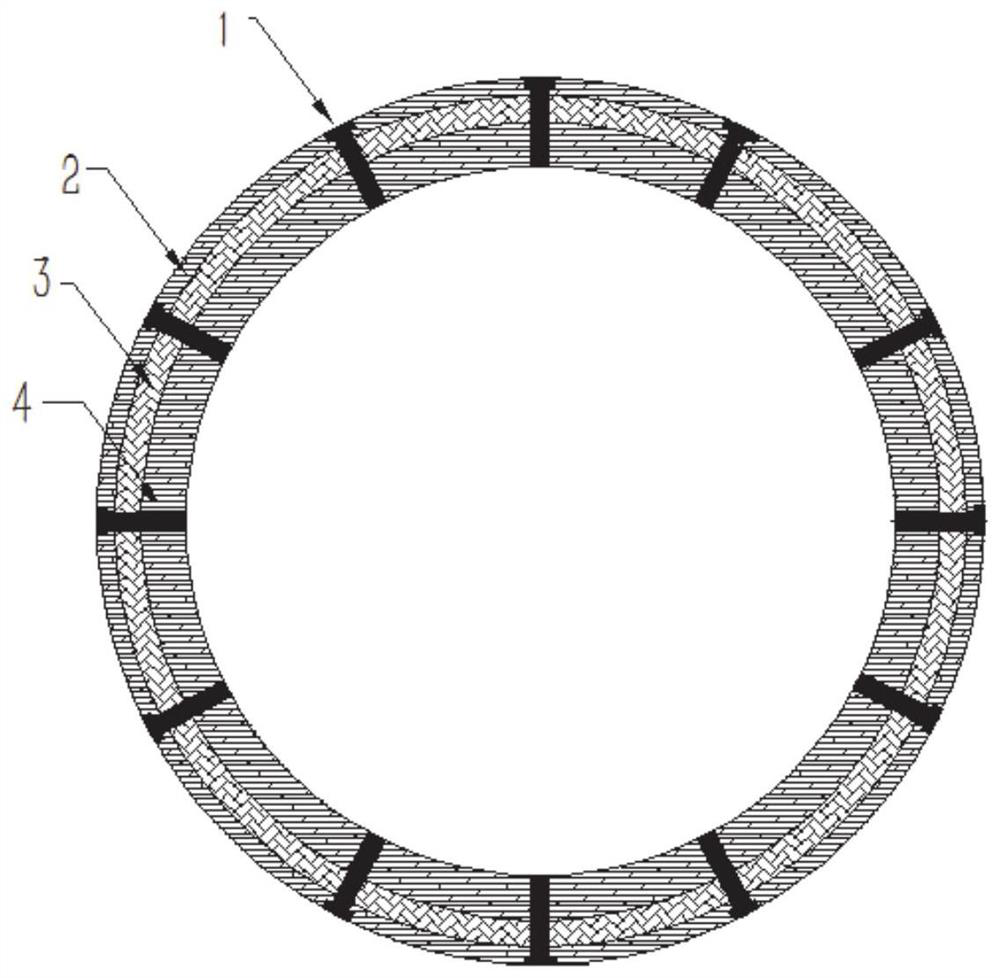

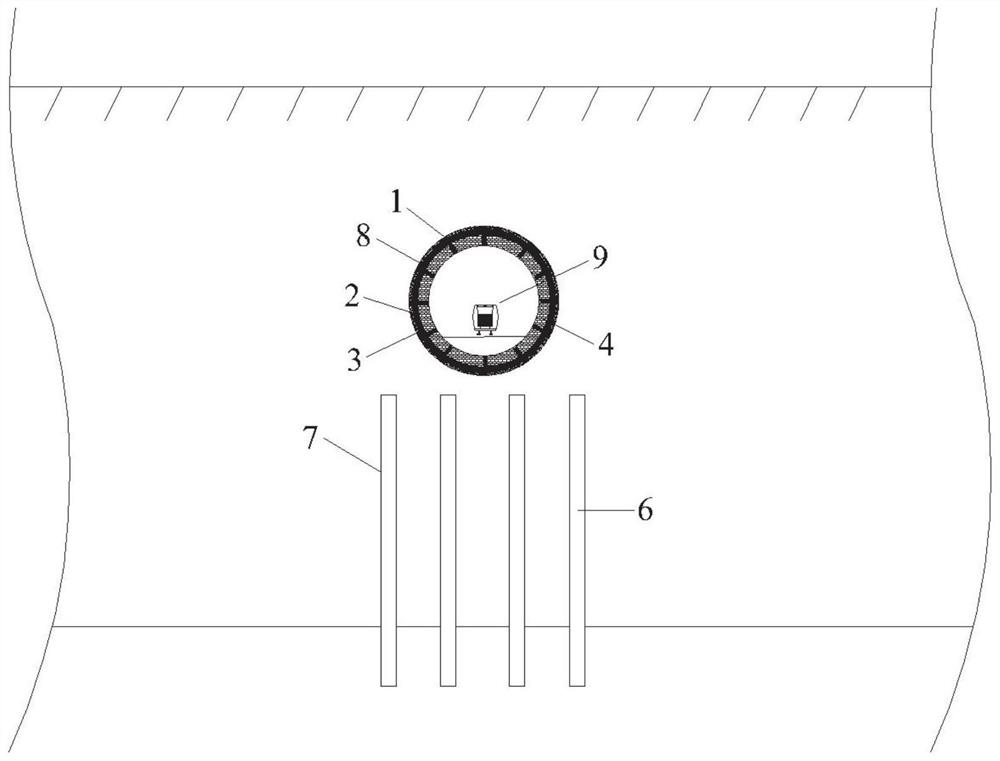

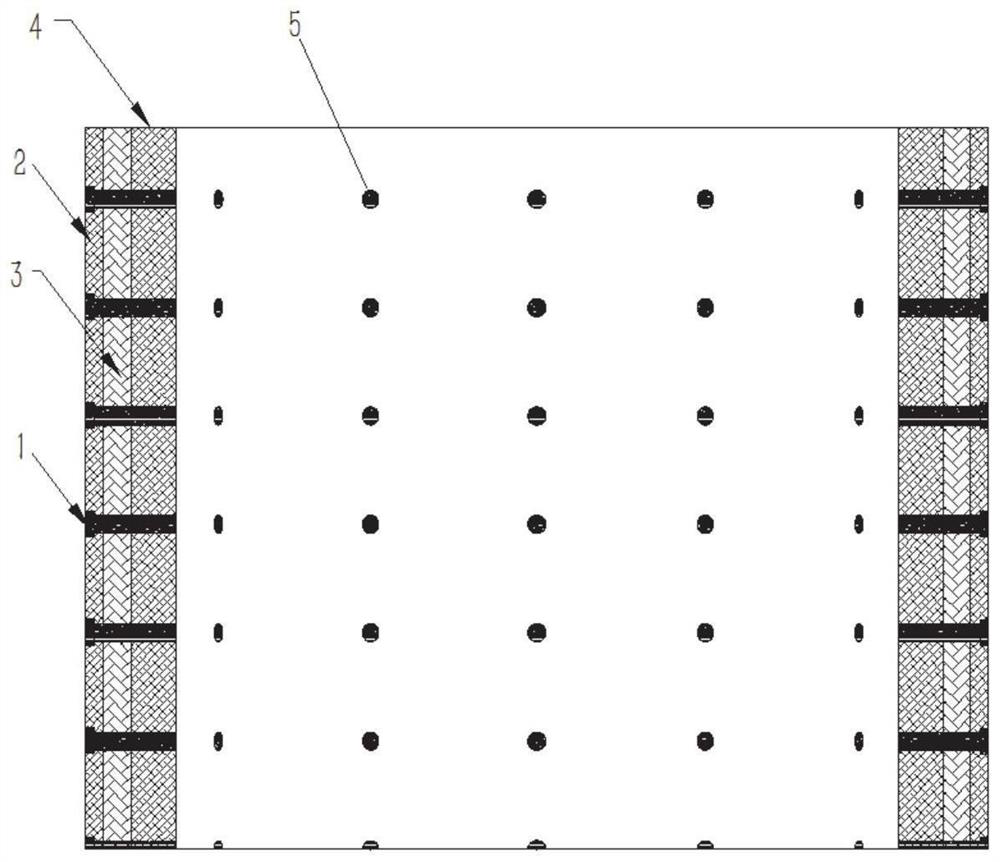

[0030] like Figure 1-Figure 4 As shown, this embodiment provides a subway tunnel system for vibration reduction and noise prevention, including a tunnel lining 8, wherein a plurality of vibration damping holes 5 penetrating the side walls of the tunnel lining 8 are provided, and the vibration damping holes 5 are provided with Porous Duxseal material 1, the vibration damping hole 5 is closed at one end of the outer wall of the tunnel lining 8, the vibration damping hole 5 is used to absorb and attenuate the medium and low frequency vibration of the side wall and inner cavity of the tunnel lining 8, and the Duxseal material 1 is used for Absorb and attenuate the high frequency vibration of the side wall and inner cavity of the tunnel lining 8 .

[0031] In this embodiment, the tunnel lining 8 includes an outer concrete pipe layer 2 and an inner concrete pipe layer 4 that are coaxial and nested with each other, and the gap between the outer concrete pipe layer 2 and the inner co...

Embodiment 2

[0046] The present embodiment provides a construction method for a vibration-damping and noise-proof subway tunnel system, comprising the following steps:

[0047] Carry out the excavation of the foundation soil below the bottom of the tunnel lining, with a width of about 10-12m, and excavate to 1-2m below the bottom lining;

[0048] Along the advancing direction of the tunnel, multiple rows of vibration isolation tubes 7 are buried at equal intervals;

[0049] The waste tire material is made into rubber particles, and the rubber particles are filled into the vibration isolation tube 7;

[0050] Backfill the excavated bottom lining and compact it to the design level.

[0051] The vibration isolation tube 7 is embedded in the soil layer below the tunnel lining 8 by drilling and burying hollow piles.

[0052] Lay tunnel lining 8 along the driving direction;

[0053] The vibration damping hole 5 is reserved in the side wall of the tunnel lining 8;

[0054] The Duxseal materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com