Annular high-precision measuring device and method based on speckle structured light

A measurement device and structured light technology, applied in the field of 3D modeling, can solve problems such as inability to integrate vertically subdivided fields, 3D reconstruction solutions that cannot be satisfied at the same time, and ignoring technical index requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention will be further described below with reference to the accompanying drawings.

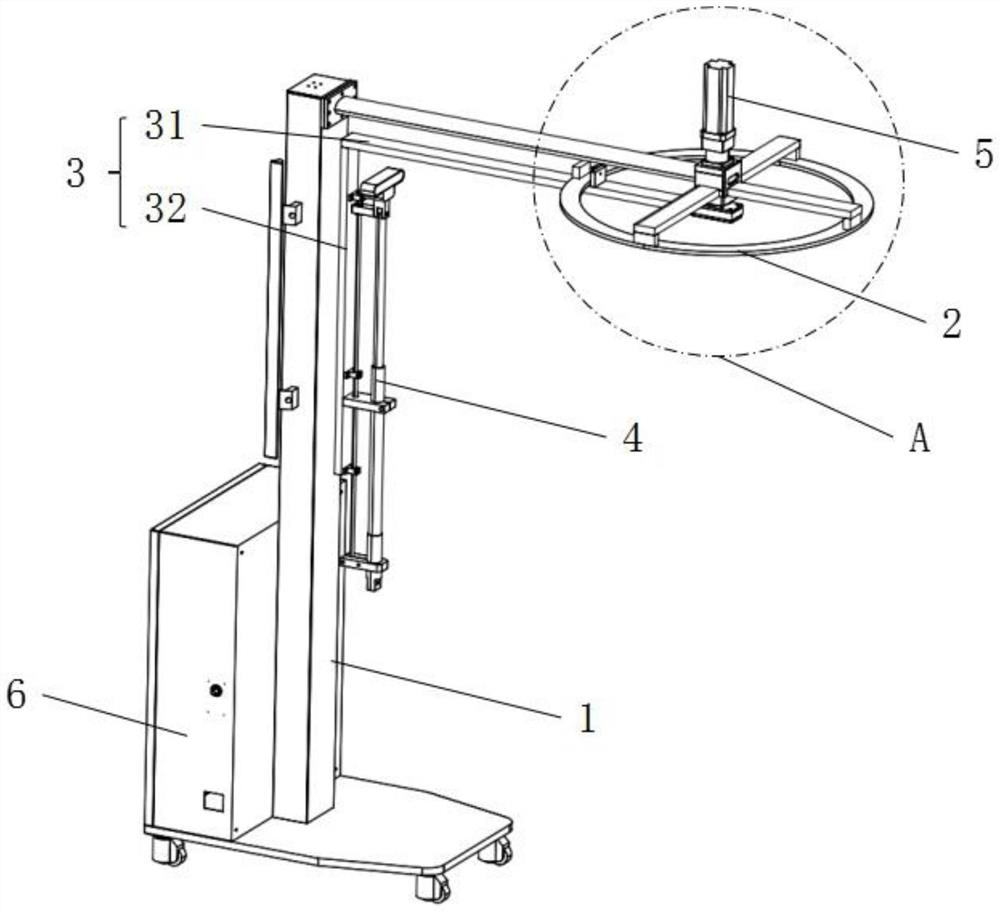

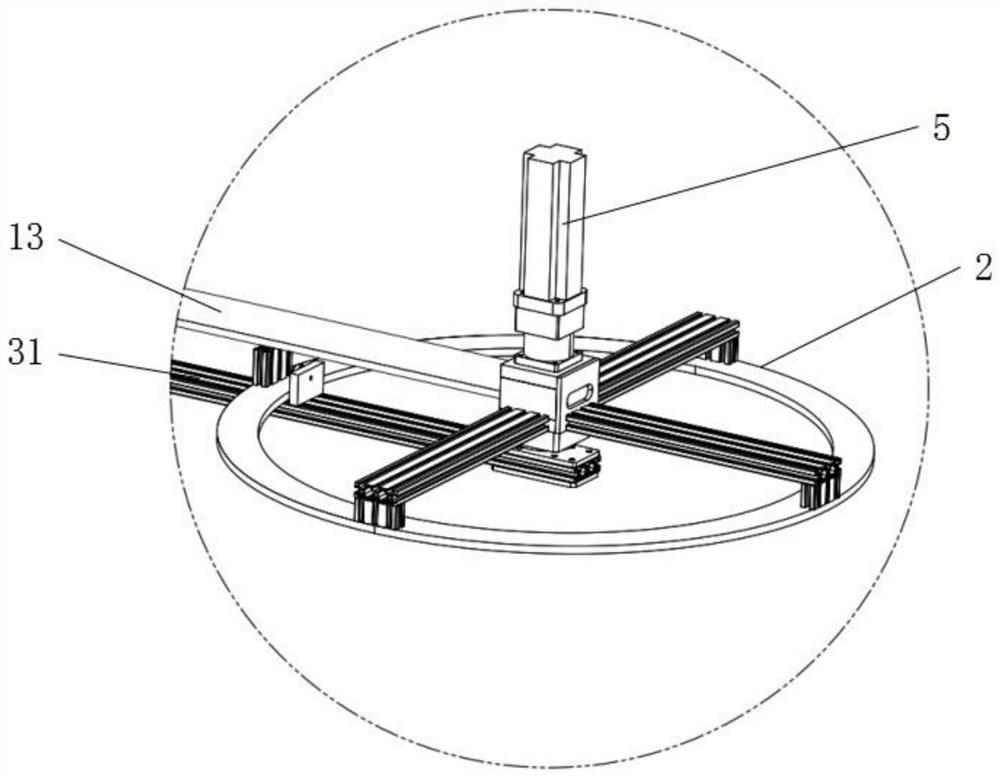

[0036] like Figure 1-4 As shown, a ring-shaped high-precision measurement device based on speckle structured light provided by this embodiment includes:

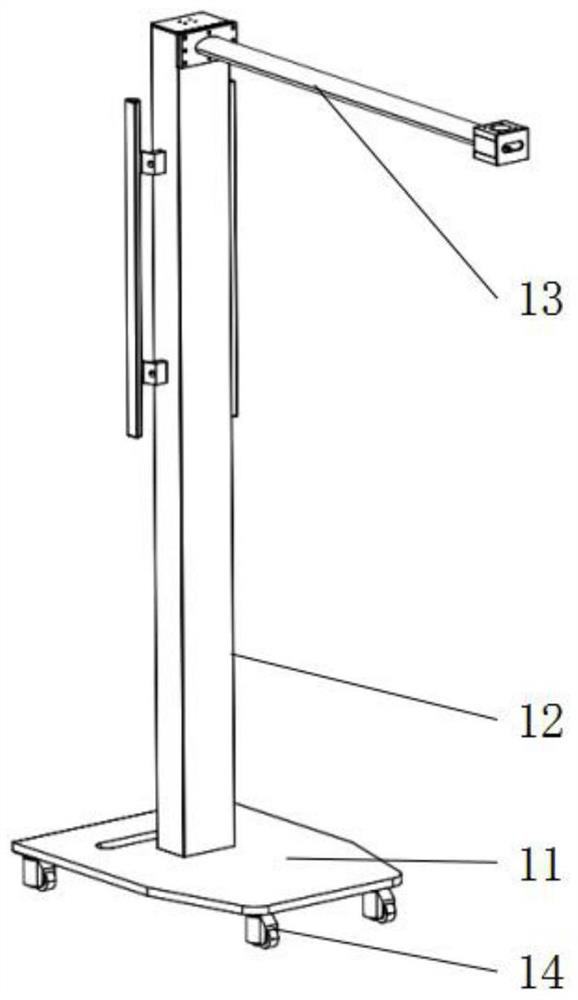

[0037] support structure 1;

[0038] an annular guide rail 2, the annular guide rail 2 is connected to one end of the support structure 1;

[0039] Cantilever 3, said cantilever 3 is rotatably connected to the lower end of said annular guide rail 2;

[0040] a depth camera module assembly 4, the depth camera module assembly 4 is vertically connected to the cantilever 3;

[0041] The servo system 5 is arranged above the annular guide rail 2 and fixed on the support structure 1 , and the output end of the servo system 5 is connected to the cantilever 3 .

[0042] The working principle and beneficial effects of the present invention are:

[0043] The present invention provides a ring-shaped high-precision measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com