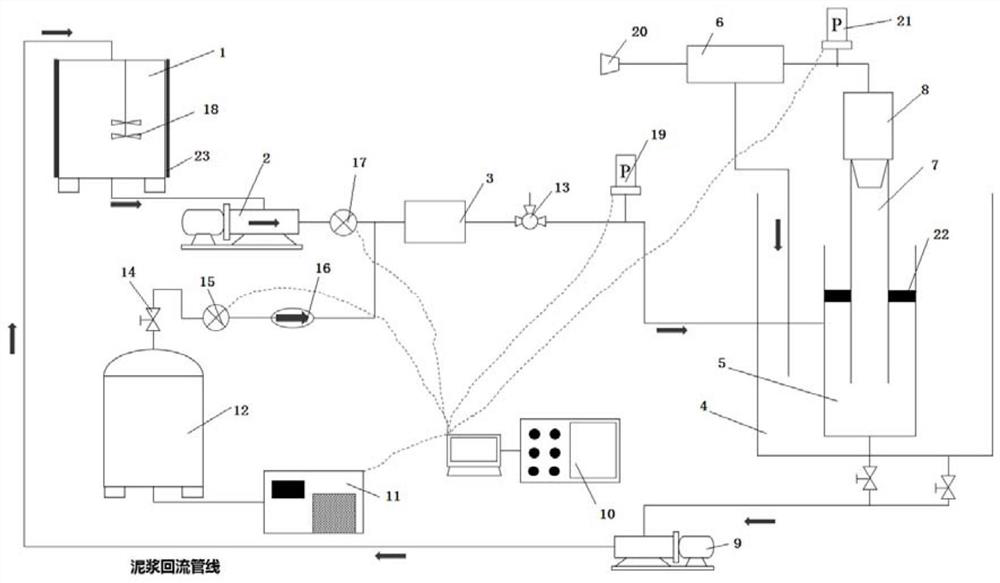

Experimental device and method for evaluating erosion resistance of check valve of arrow-shaped drilling tool under condition of simulating internal spraying of gas well drilling tool

An experimental device, check valve technology, applied in the direction of mechanical valve testing, etc., can solve the problem of no arrow-shaped drilling tool check valve erosion performance evaluation research, no study of safety grabbing operation time, and inability to simulate mixing and continuous spraying Erosion arrow drill tool check valve and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

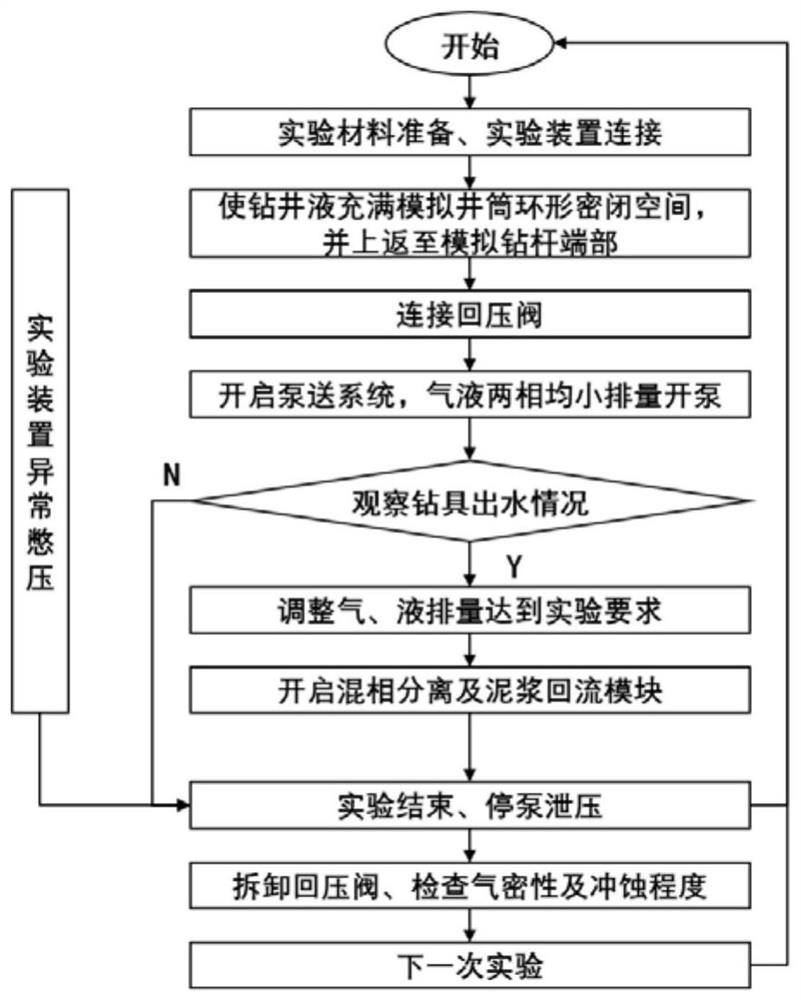

[0059] Such as figure 2 As shown, an experimental method for evaluating the anti-erosion performance of arrow-shaped drilling tool check valve under the condition of simulating gas well drilling tool internal injection, using the above-mentioned experimental device, includes the following steps:

[0060] (1) According to the drilling status of the experimental target block, the corresponding experimental drilling fluid is prepared and placed in the mud storage tank 1, and the prepared density is 1.9g / cm 3 The experimental drilling fluid was placed in the mud storage tank 1 and the agitator 18 was turned on to prevent the drilling fluid from consolidating. The electric heating jacket 23 was installed and adjusted to 80°C to preheat the drilling fluid for 3 hours, and the agitator 18 was turned on to prevent the drilling fluid from solidifying. Liquid solidification, the electric heating jacket 23 is installed on the outside of the mud storage tank 1, and the drilling fluid is ...

Embodiment 2

[0071] Such as figure 2 As shown, an experimental method for evaluating the anti-erosion performance of arrow-shaped drilling tool check valve under the condition of simulating gas well drilling tool internal injection, using the above-mentioned experimental device, includes the following steps:

[0072] (1) According to the drilling status of the experimental target block, the corresponding experimental drilling fluid is prepared and placed in the mud storage tank 1, and the prepared density is 1.9g / cm 3 The experimental drilling fluid was placed in the mud storage tank 1 and the agitator 18 was turned on to prevent the drilling fluid from consolidating. The electric heating jacket 23 was installed and adjusted to 80°C to preheat the drilling fluid for 3 hours, and the agitator 18 was turned on to prevent the drilling fluid from solidifying. Liquid solidification, the electric heating jacket 23 is installed on the outside of the mud storage tank 1, and the drilling fluid is ...

Embodiment 3

[0083] Such as figure 2 As shown, an experimental method for evaluating the anti-erosion performance of arrow-shaped drilling tool check valve under the condition of simulating gas well drilling tool internal injection, using the above-mentioned experimental device, includes the following steps:

[0084] (1) According to the drilling status of the experimental target block, the corresponding experimental drilling fluid is prepared and placed in the mud storage tank 1, and the prepared density is 1.9g / cm 3 The experimental drilling fluid was placed in the mud storage tank 1 and the agitator 18 was turned on to prevent the drilling fluid from consolidating. The electric heating jacket 23 was installed and adjusted to 80°C to preheat the drilling fluid for 3 hours, and the agitator 18 was turned on to prevent the drilling fluid from solidifying. Liquid solidification, the electric heating jacket 23 is installed on the outside of the mud storage tank 1, and the drilling fluid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com