System-level reinforcement method and circuit for high-voltage diodes used in aerospace against single-event burning

A high-voltage diode, anti-single event technology, applied in the direction of utilizing plasma, control/regulation system, high-efficiency power electronic conversion, etc., can solve the limitation of SiCSBD device aerospace application pace, device power loss and reverse recovery time increase, reinforcement means Insufficient and other problems, to achieve the effect of improving the anti-single event burnout voltage level, reducing the possibility of device failure, and making the process implementation less difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

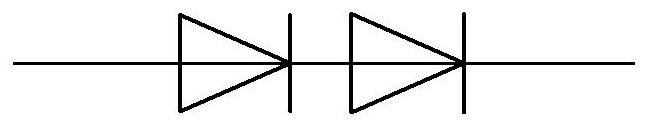

[0032] Such as figure 1 The diode series structure shown in this embodiment can be used for system-level reinforcement of high-voltage diodes against single event burning.

[0033] Typical application scenarios of the system-level hardening method proposed in this embodiment are as follows:

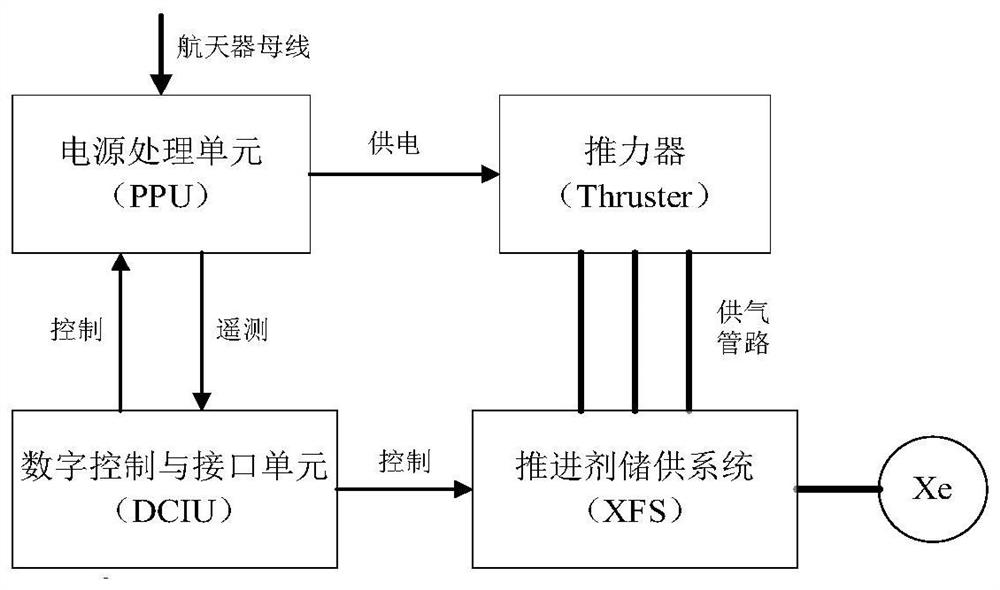

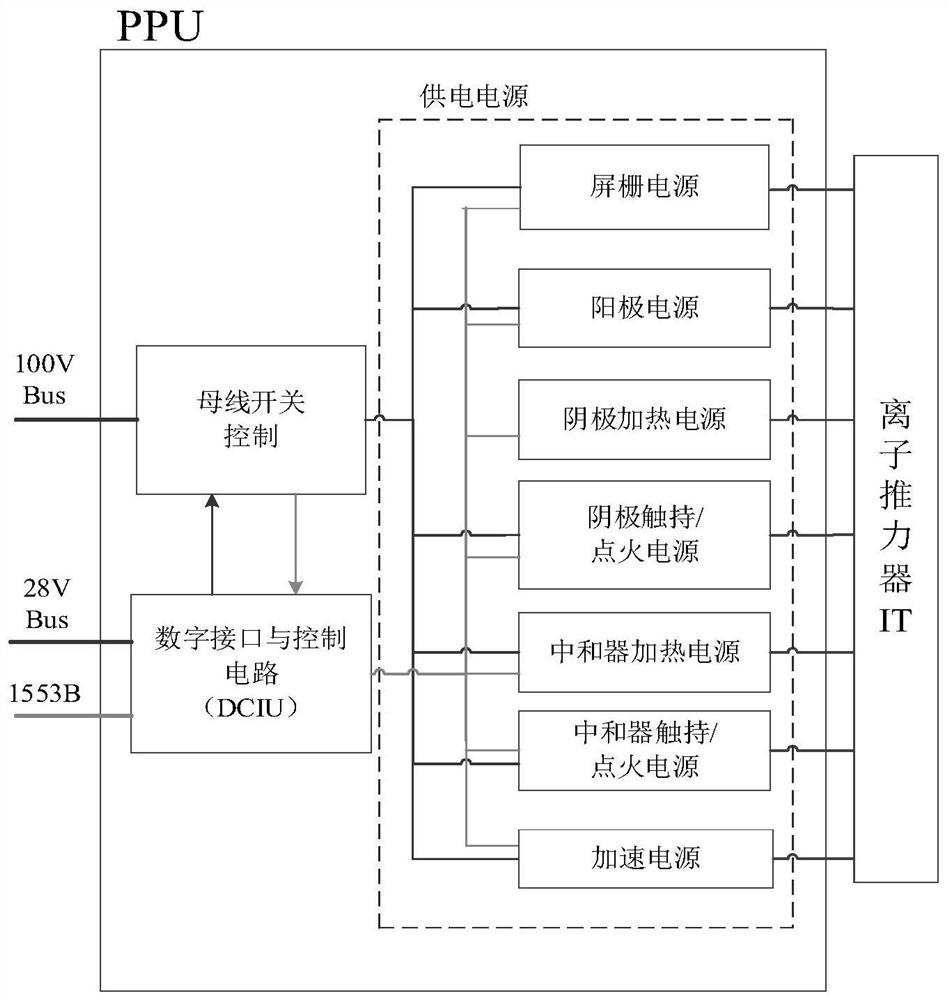

[0034] As an advanced propulsion technology, electric propulsion has become an important indicator to measure the advanced nature of a satellite due to its advantages of high specific impulse, which can reduce the quality of the spacecraft system, improve the service life and increase the payload. figure 2 It is a schematic diagram of the composition of the electric propulsion system, which consists of four parts: thruster, power processing unit (Power Processing Unit, PPU), propellant supply system (Xenon Feed System, XFS) and digital control and inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com