Component carrier structure aligned by combining evaluation pad pattern and hole pattern alignment marks

A technology for component bearing and alignment marks, which is used in electrical components, multilayer circuit manufacturing, printed circuit manufacturing, etc., to achieve high-precision and high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

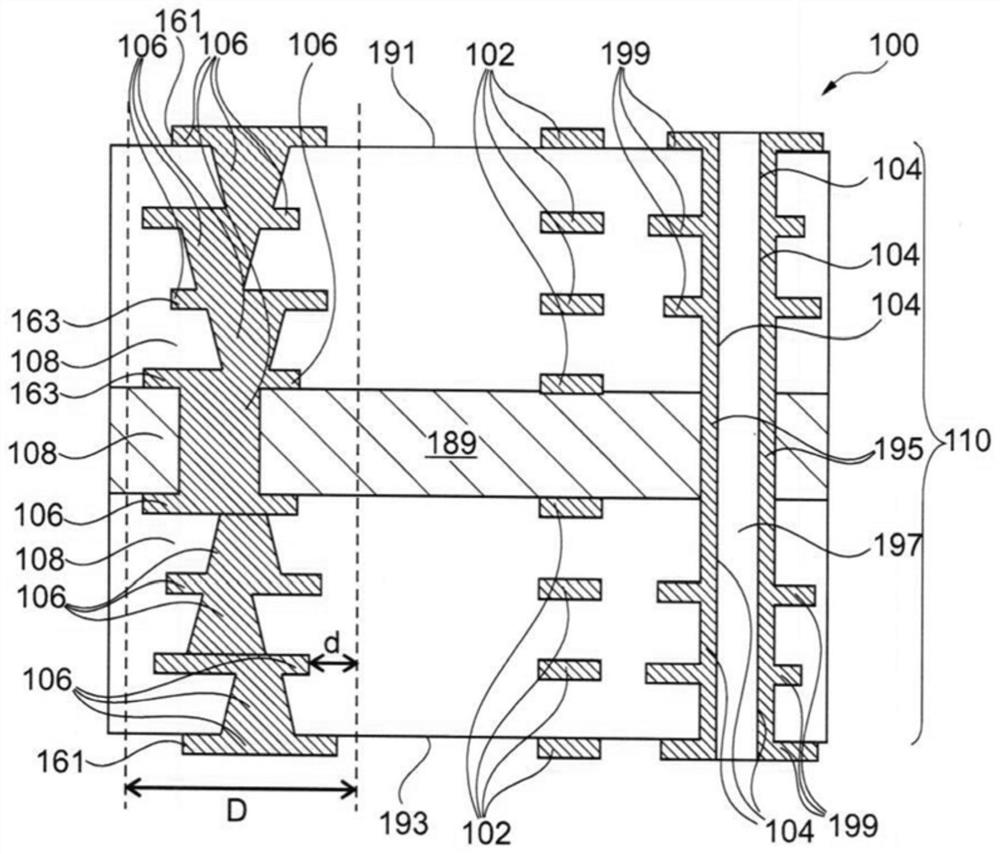

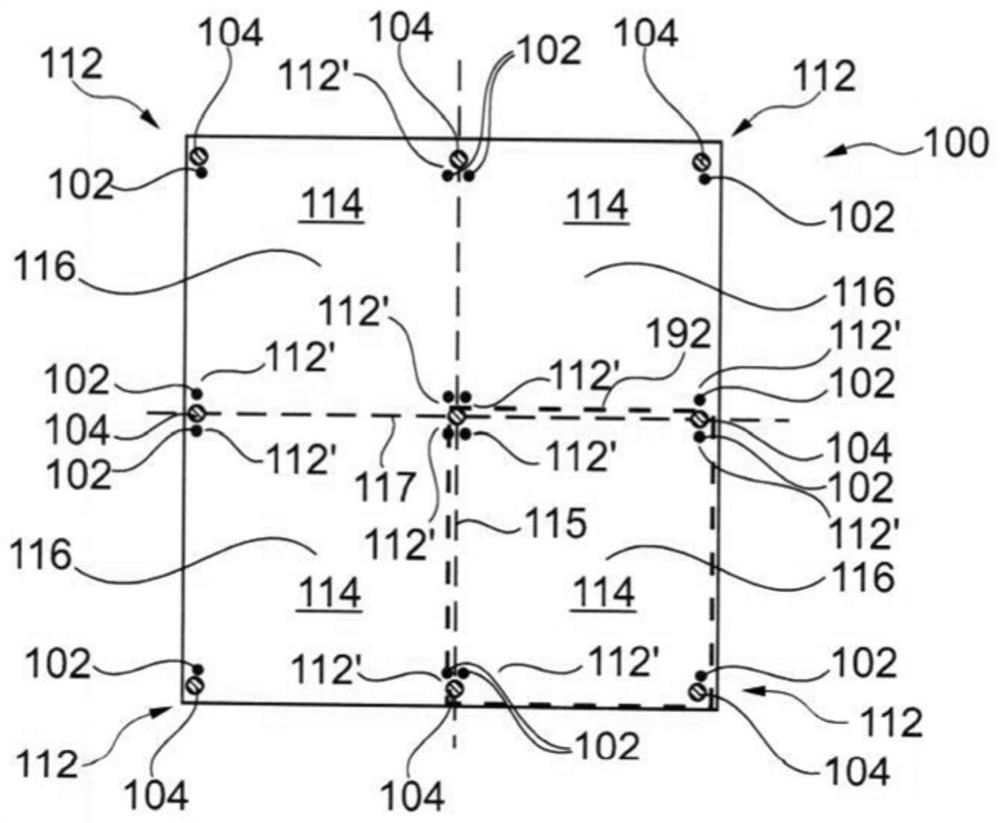

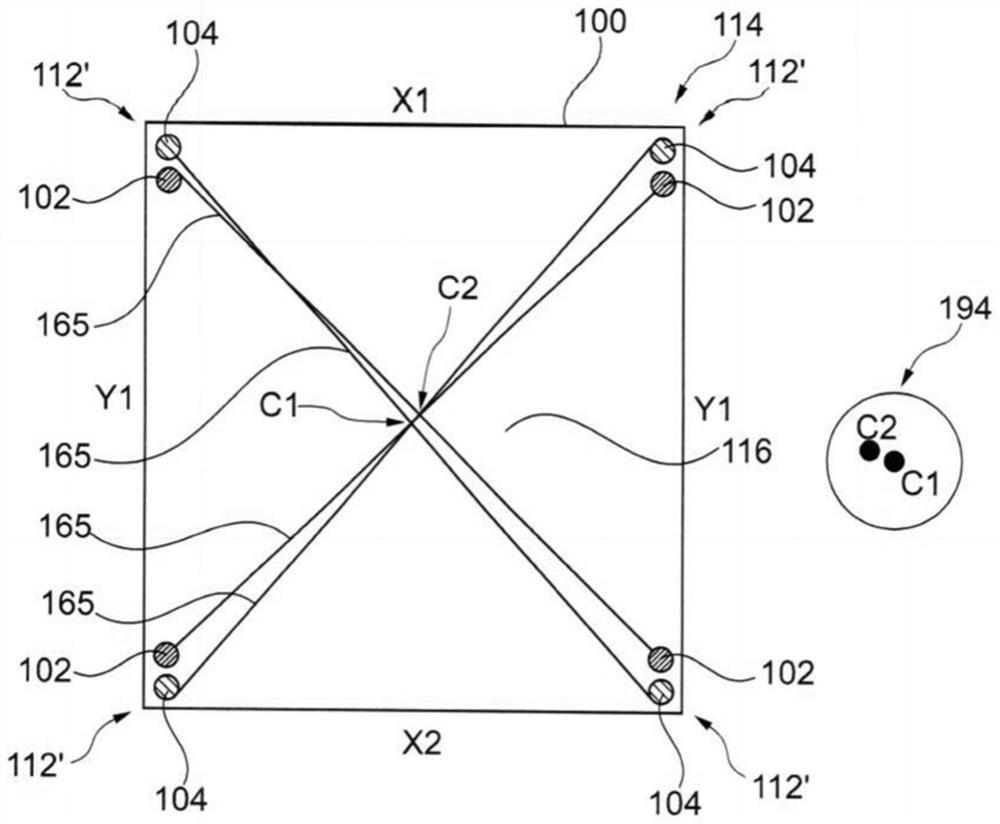

[0066] Exemplary embodiments will be described in further detail, and some basic considerations will be summarized based on exemplary embodiments of the present invention that have been developed, before referring to the drawings.

[0067] According to an exemplary embodiment of the present invention, the determination of alignment information based on pad-type alignment marks is synergistically combined with the determination of alignment information based on one or more hole-type alignment marks.

[0068] In a particularly preferred embodiment, it has been found that pad alignment alone is more accurate than hole alignment. Therefore, according to an exemplary embodiment of the present invention, preliminary alignment information may be derived using pad alignment alone, ie hole type alignment marks are not considered in this first stage. Subsequently, the alignment information may be made more accurate, more precise or may be improved by additionally taking into account the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com