Product taking-out mechanism for battery box forming equipment

A molding equipment and product removal technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of battery box collision, rupture, etc., and achieve the effect of increasing adsorption capacity, easy adsorption, and avoiding tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

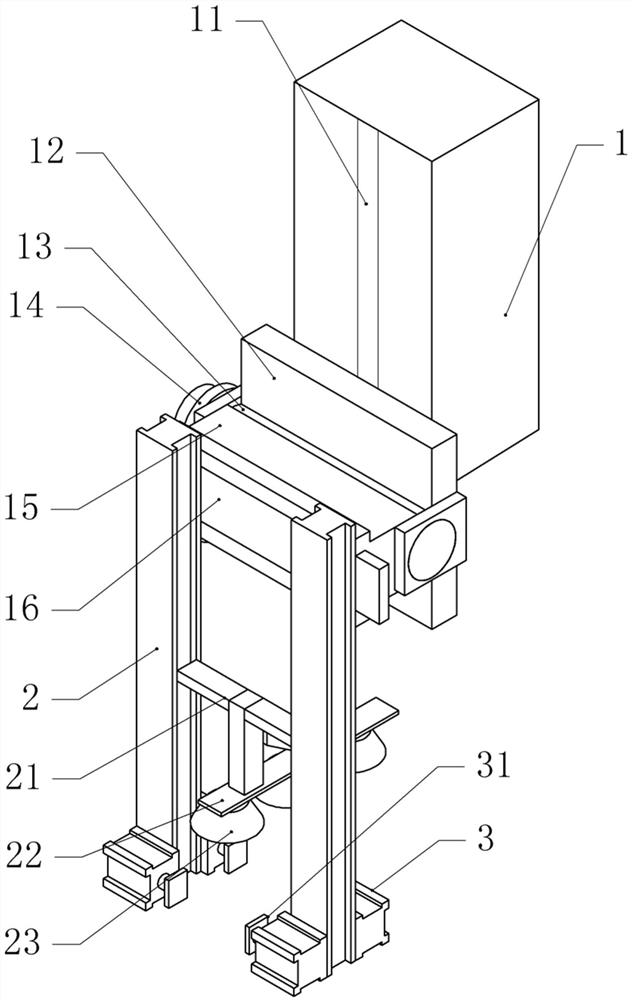

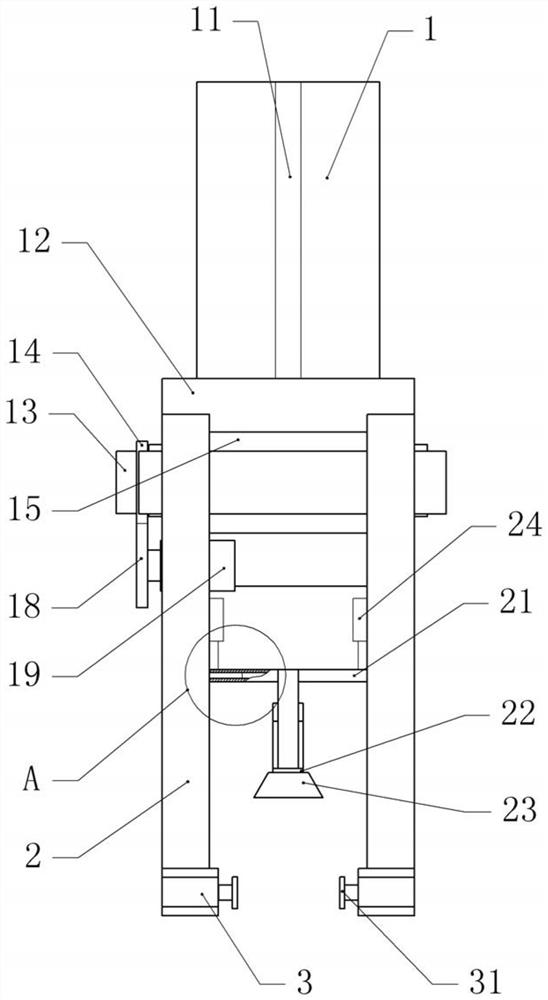

[0036] Basic as attached figure 1 And attached figure 2 Shown: a product take-out mechanism for battery box forming equipment, including a frame and a first linear module fixed on the frame with bolts, and a vertical bracket is bolted on the output end of the first linear module 1. A second vertical linear module 11 is fixed on the bracket 1 by bolts, and a fixed seat 12 is fixed by bolts on the output end of the second linear module 11. A steering mechanism is arranged on the fixed seat 12, and a clip is installed on the steering mechanism. holding mechanism and adsorption mechanism. When the first linear motor module is working, the support 1 is moved to the injection molding machine. When the second linear motor module is working, the position of the fixing seat 12 can be adjusted vertically, and then the height of the steering mechanism and the adsorption mechanism can be adjusted.

[0037] In this embodiment, the steering mechanism includes a rotating shaft 13 and a mo...

Embodiment 2

[0045] The difference between embodiment two and embodiment one is that, as attached Image 6 , attached Figure 7 And attached Figure 8 As shown, the negative pressure pump 4 is fixed with bolts on the bracket 1 , the air inlet of the negative pressure pump 4 is communicated with an air intake pipe 41 , the air intake pipe 41 is communicated with the sucker 23 , and the air outlet of the negative pressure pump 4 is communicated with an air outlet pipe 42 .

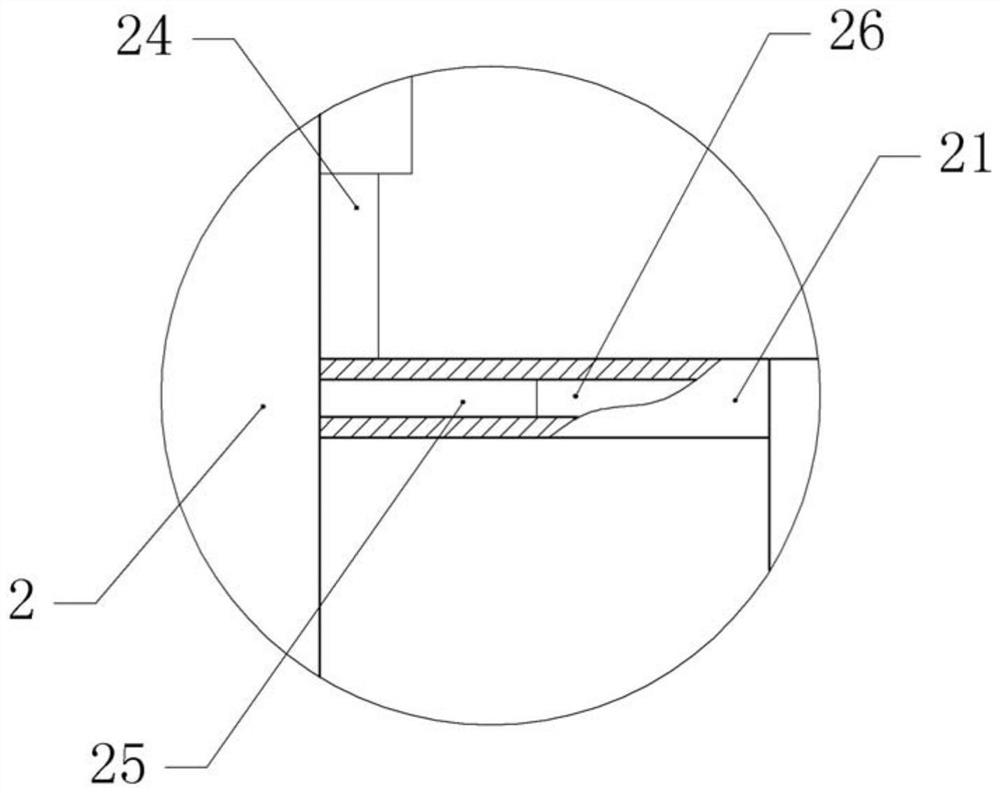

[0046] A cavity 34 is opened in the main clamping plate 31, and a secondary clamping plate 32 is horizontally slidably connected to both sides of the cavity 34. A return spring 36 is arranged between the two secondary clamping plates 32, and the cavity 34 passes through the outlet. The gas pipe 42 communicates with the negative pressure pump 4 , and the cavity 34 communicates with a pressure relief valve 35 . combined with Figure 8 As shown, several protrusions 33 are vertically slidably connected to the auxiliary cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com