Pump core of independent external spring pump

A self-contained, pump core technology, applied in injection devices, closures, packaging, etc., can solve the problems of corrosive metal springs, mosquitoes polluting materials, and inflexible use, so as to reduce product development and manufacturing costs, prevent loosening, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

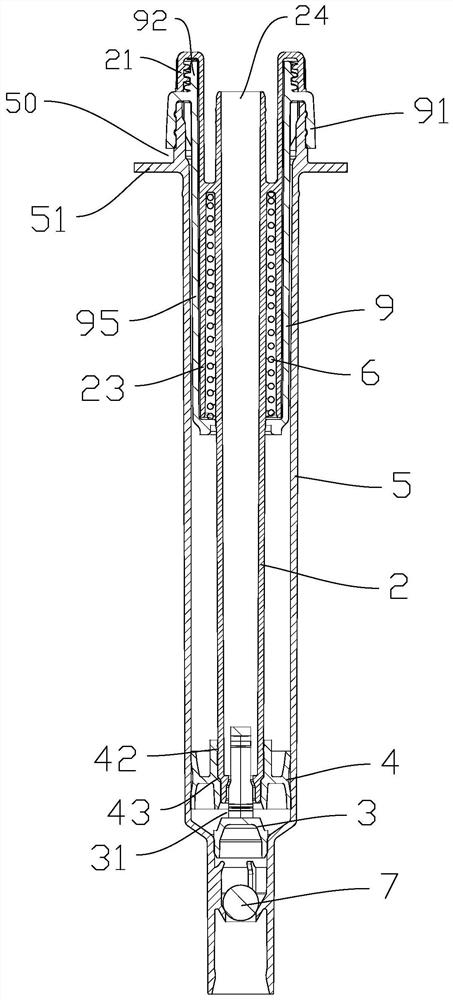

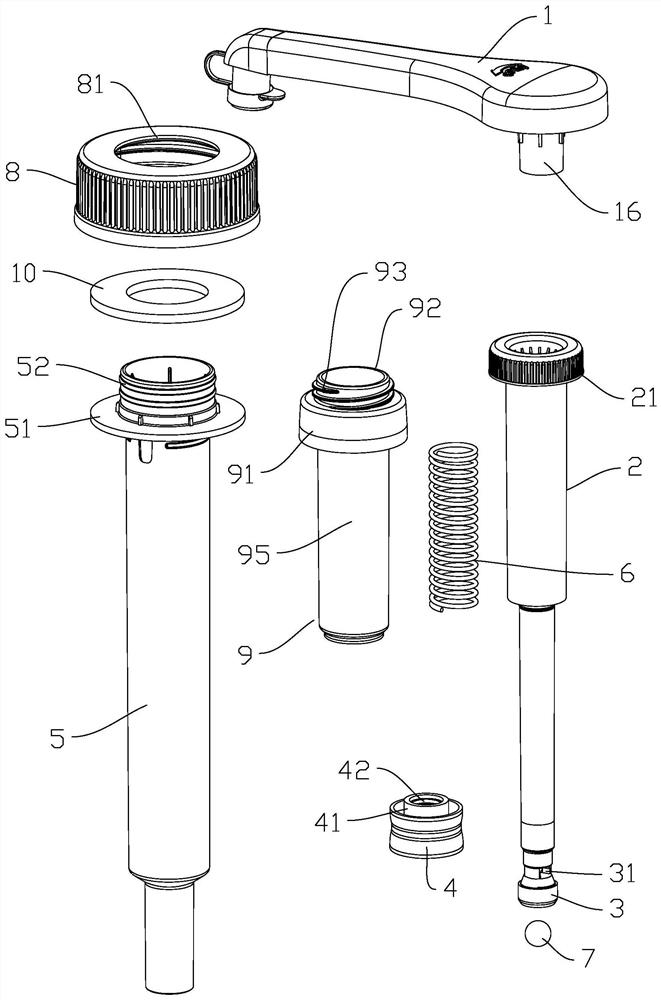

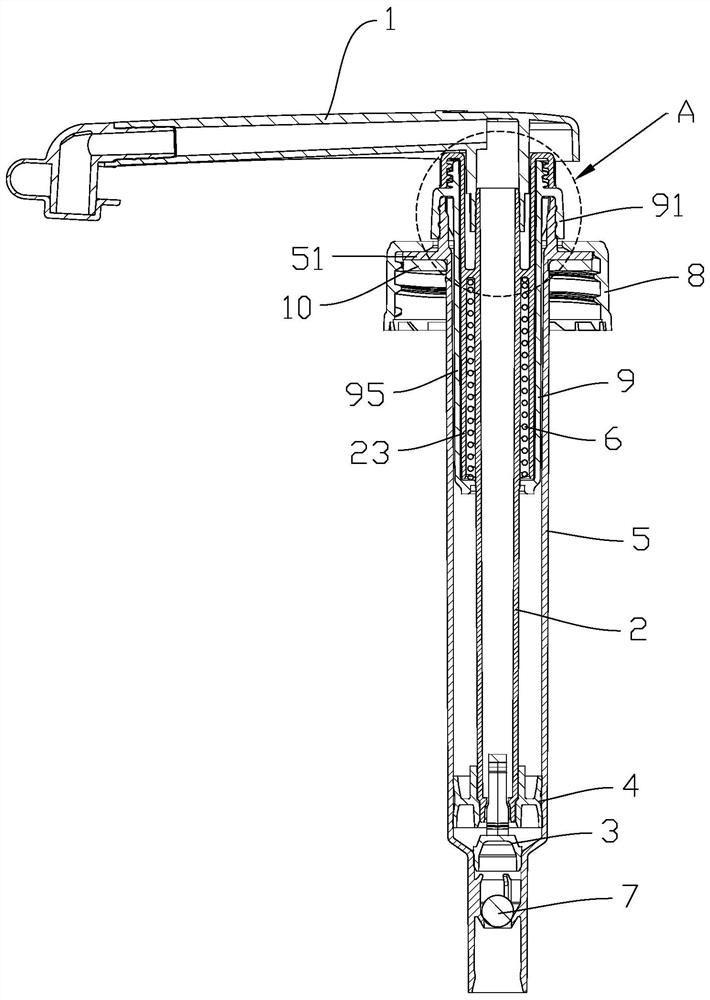

[0022] Such as Figure 1 to Figure 4 As shown, an independent external spring pump core includes a main column 2, an auxiliary column 3, a piston 4, a pump chamber 5, a spring 6 and glass beads 7, and the main column 2 is arranged in the pump chamber 5, so that The auxiliary column 3 is connected to the lower end of the main column 2, the piston 4 is sleeved on the outside of the main column 2 and the auxiliary column 3, and the pump chamber is fixed with a lock cover 9 capable of fixing the main column 2 on the pump chamber 5, The outer side of the upper end of the lock cover 9 is provided with a cover flange 91 that is turned outwards and then turned downwards. The upper end of the pump chamber 5 is plugged and fixed on the inner side of the cover flange 91. The lock cover 9 is provided with a locking opening 92 that protrudes upwards above the cover flange 91, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com