Screening equipment with automatic rice gathering and conveying functions

A technology of screening equipment and functions, which is applied in the field of screening equipment with the function of automatic rice transportation, can solve the problems of low efficiency, excessive human resources, and increased workload of farmers, and achieve the effect of reducing workload and achieving good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

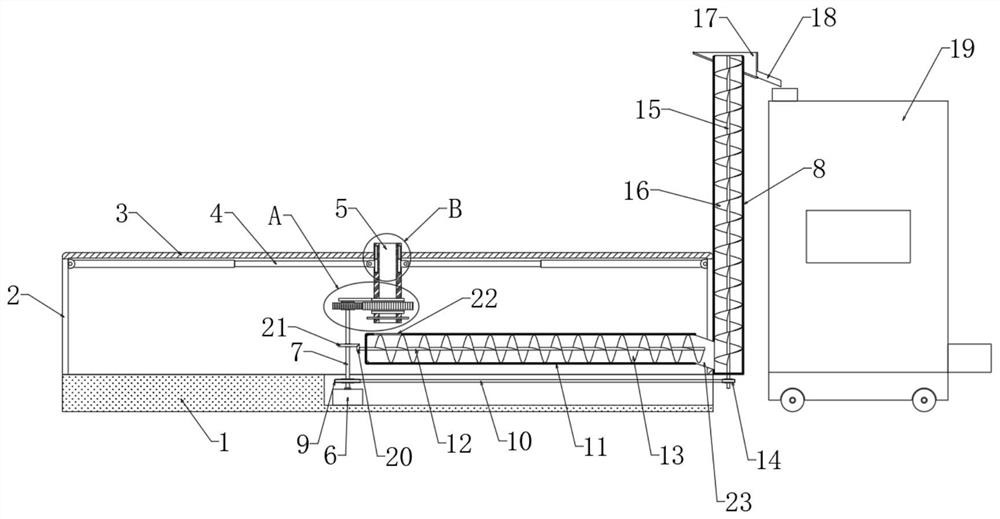

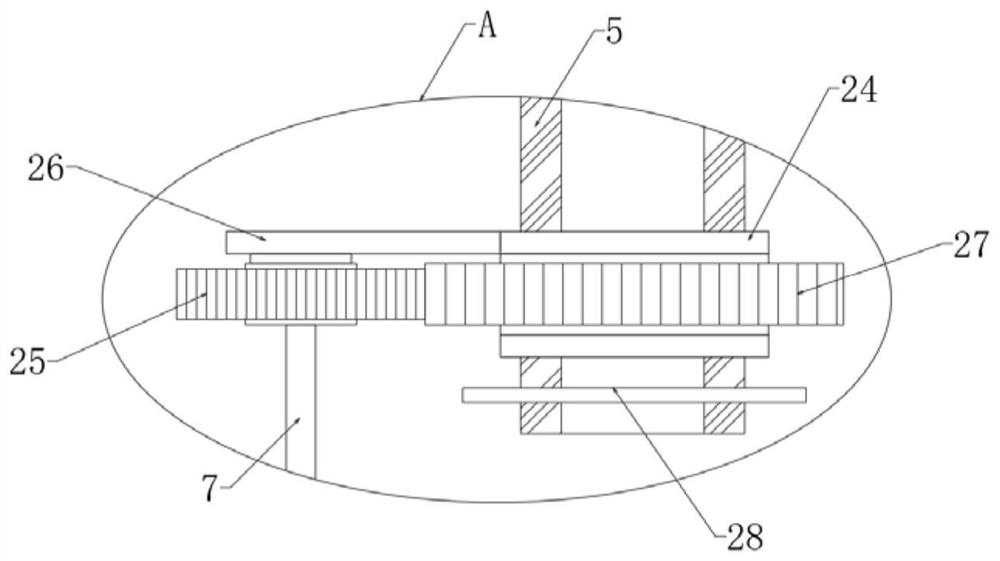

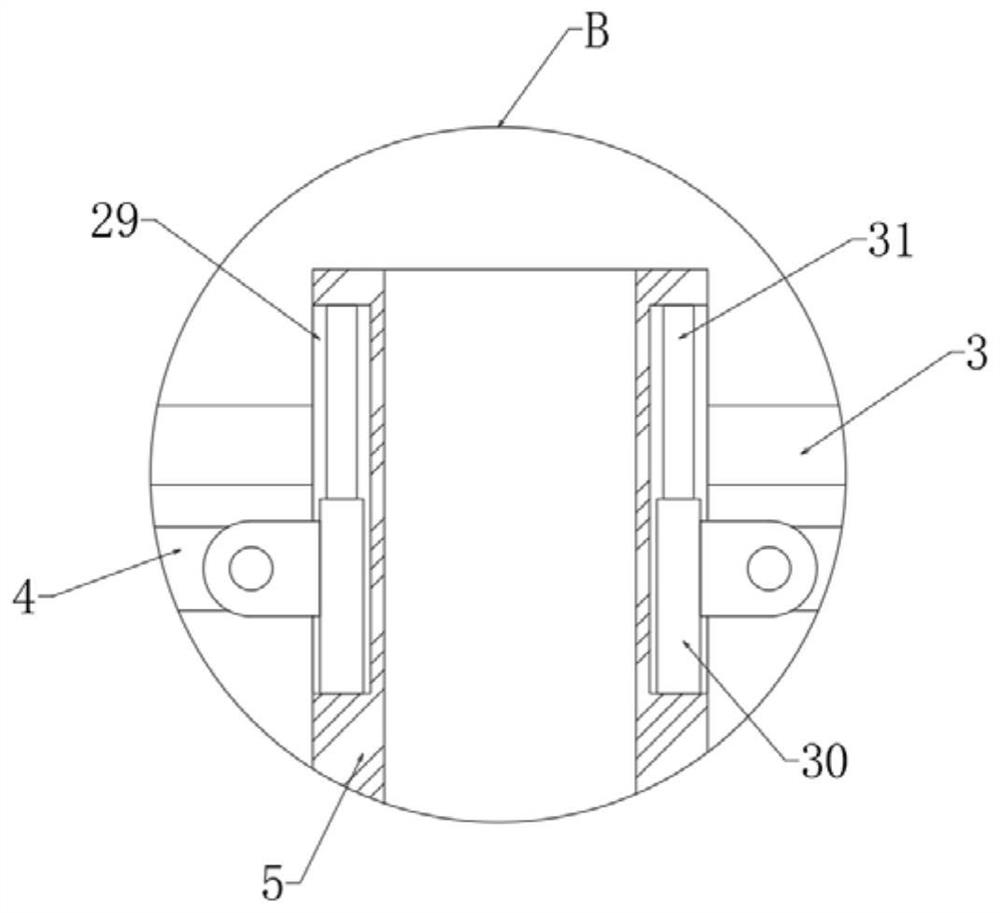

[0026] refer to Figure 1-5 , a screening device with the function of automatically picking up rice and conveying, comprising a screening machine body 19 and a base 1, the base 1 is fixedly connected with an annular bracket 2, the annular bracket is fixedly connected with an elastic drying cloth 3, and the inner wall of the annular bracket 2 is fixedly connected There is a U-shaped support 24, the first gear 27 is installed in the U-shaped support 24, the U-shaped support 24 is provided with a feed pipe 5 that is movably connected with it up and down, and the U-shaped support 24 is provided with a communication groove. 5 runs through the communication groove and does not offset it; the feed pipe 5 runs through the first gear 27 and is threadedly connected with it, the inner ring of the first gear 27 is provided with internal threads, and the outer wall of the feed pipe 5 is provided with external threads.

[0027] The feeding pipe 5 runs through the center of the elastic dryin...

Embodiment 2

[0037] refer to figure 1 and 6 The difference between this embodiment and Embodiment 1 is that the outer wall of the feeding pipe 5 in this embodiment is provided with a sliding ring 35 slidingly connected with it, and the upper end of the side wall of the feeding pipe 5 is fixedly connected with a limit ring 34, and the elastic drying cloth 3. It is fixedly connected with the outer wall of the sliding ring 35; when the feeding pipe 5 moves downward, the sliding ring 35 moves and resists the limit ring 34, so that the mouth of the feeding pipe 5 can be lowered as much as possible, which can be more effective The gathered rice is transported.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com