Traffic road and bridge construction material mixing treatment device

A technology of material mixing, traffic road and bridge, applied in the direction of roads, roads, road repairs, etc., can solve the problems that affect the efficiency of construction, consume a lot of manpower and time, and achieve the effect of avoiding mutual interference, good effect, and improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

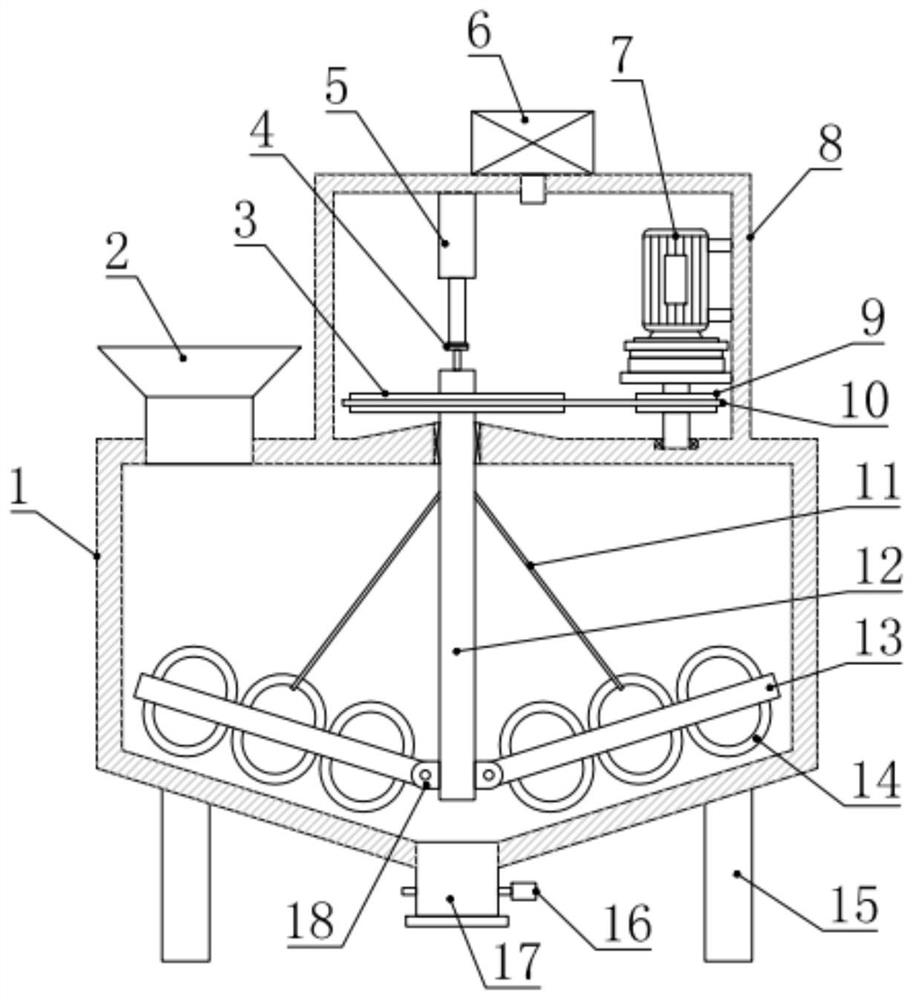

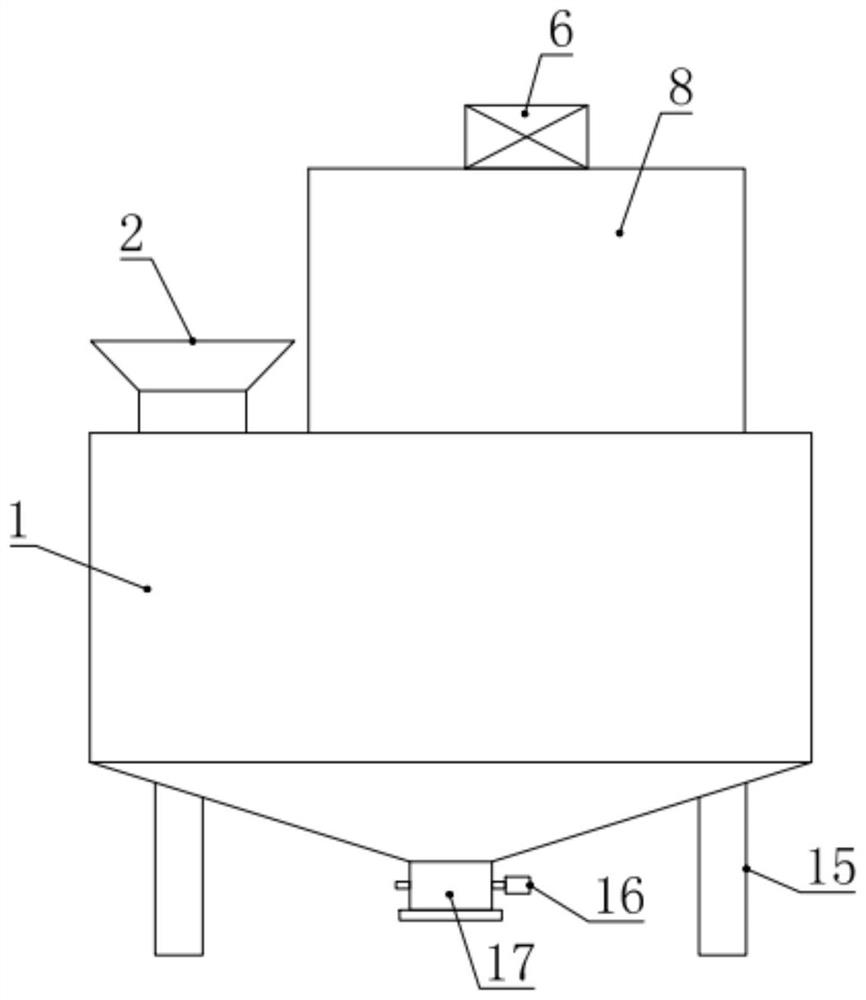

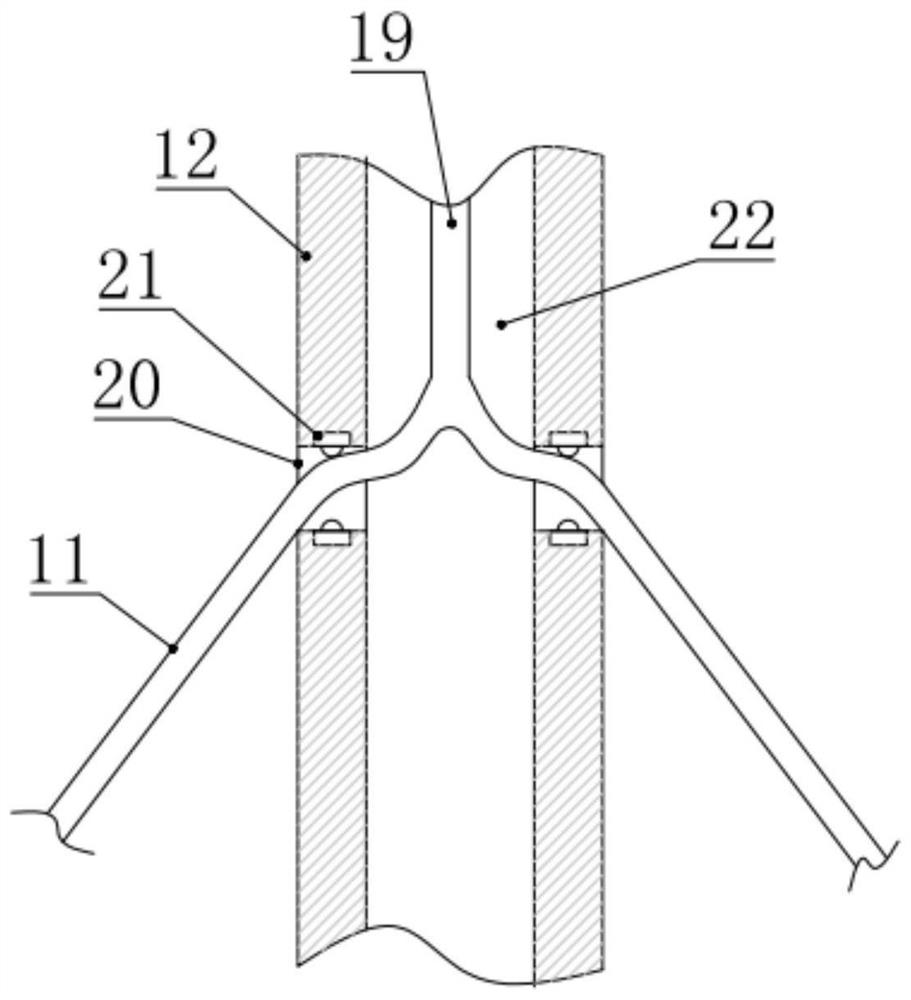

[0026] see Figure 1-2 , in an embodiment of the present invention, a device for mixing and processing traffic, road and bridge construction materials includes a mixing box 1 and a driving box 8, the driving box 8 is installed and fixed on the top of the mixing box 1, and a center is installed in the middle of the mixing box 1 Rotary tube 12, the central rotary tube 12 is connected with the top of the mixing box 1 in a sealed rotation, the upper end of the central rotary tube 12 is located in the drive box 8, and a cavity 22 is provided in the central rotary tube 12, and the inner cavity of the drive box 8 passes through the cavity. The cavity 22 communicates with the inner cavity of the mixing box 1, and the central transfer tube 12 is driven to rotate by the driving mechanism arranged in the driving box 8, and the driving mechanism includes a driven pulley 3, a driving motor 7, a driving pulley 9 and a transmission belt 10 , the driven pulley 3 is installed and fixed on the ...

Embodiment 2

[0029] see figure 1 , 3 And 4, the difference between this embodiment and embodiment 1 is:

[0030] In this embodiment, the stirring mechanism 23 includes a stirring rod 13, a stirring ring 14 and a hinge support 18, the hinge support 18 is fixed on the lower end of the central rotating tube 12, and the hinge support 18 is hinged with a stirring rod 13 , the upper and lower sides of the stirring rod 13 are respectively installed and fixed with a plurality of semicircular stirring rings 14, and the cooperation of the stirring rod 13 and the stirring ring 14 has a good mixing effect on the material; one of the upper sides of the stirring rod 13 A steel wire rope 11 is connected to the stirring ring 14, and the other end of the steel wire rope 11 is connected to the lower end of the main steel wire rope 19 provided in the cavity 22. 4. It is used to prevent the main steel wire rope 19 and the support steel wire rope 11 from twisting the telescopic cylinder 5 when they rotate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com