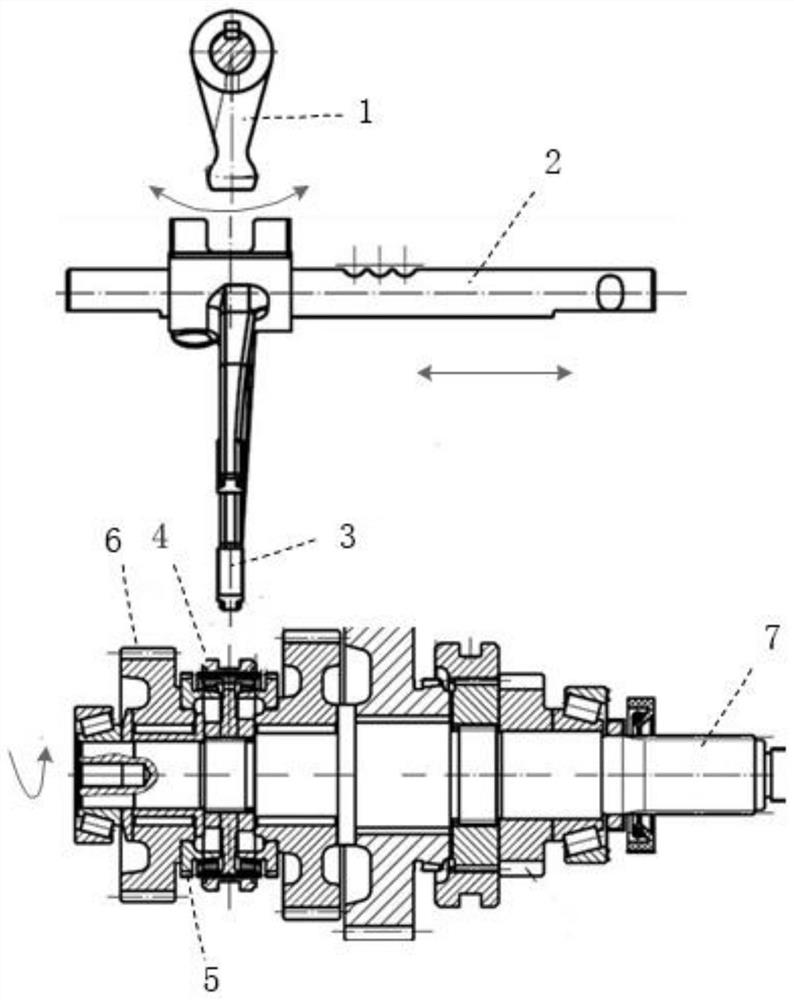

A wear warning control method for an automatic transmission shift system

A technology of automatic transmission and control method, applied in the field of transmission system, can solve the problems of wear and tear of the shifting system, inability to effectively identify the amount of wear, frequent occurrence, etc., and achieve the effect of reducing the frequency of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

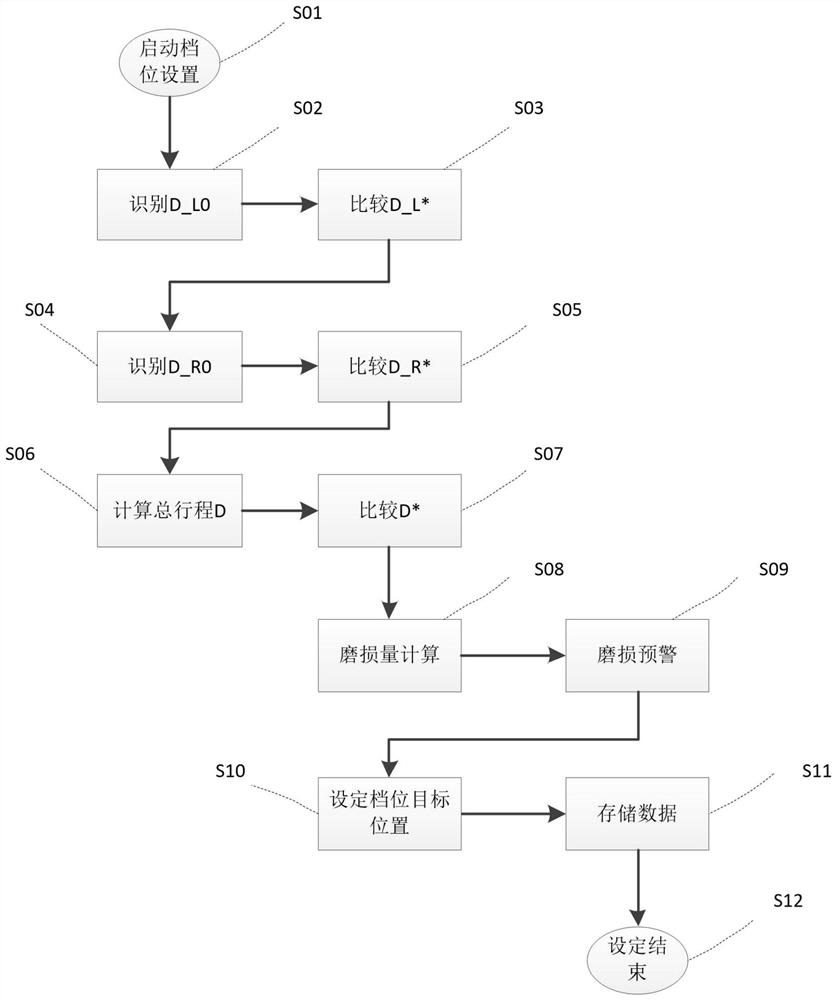

[0044] Step 3, calculate D (corresponding to S06 in Figure 3), D is the total stroke of the shifting system, D=|D_L0|+|D_R0|;

[0047] Specifically, the total wear setting value is set according to the size value of the shifting system, and the trend is: if shifting

[0048] In this embodiment, the calculation method of the total wear amount of the shifting system is clarified, when ΔD is greater than the total wear

[0050]ΔD_L0=|D_L0|‑|D_L*|, wherein, ΔD_L0 is the wear amount of the left side of the shifting system, D_L* is

[0052]△D_L0=|D_L0|‑|D_L*|=|‑8.5|‑|‑8|=0.5mm;

[0053]ΔD_R0=|D_R0|‑|D_R*|, wherein, ΔD_R0 is the wear amount of the right side of the shifting system, and D_R* is

[0055] Then △D_R0=|D_R0|‑|D_R*|=|8.5|‑|8|=0.5mm;

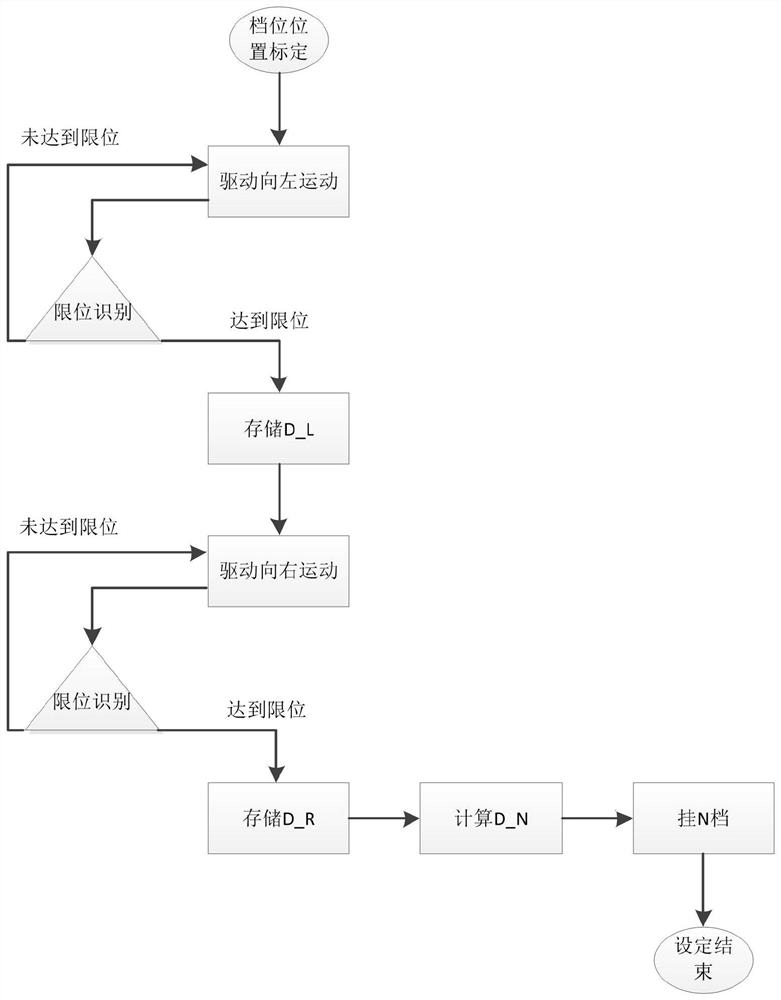

[0059] D_L is the gear setting position to the left,

[0060] D_N is a neutral setting position that does not consider wear compensation,

[0061] D_R is the gear setting position to the right,

[0071] A regular start-up program is set in the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com