A method for preventing aeroengine low-pressure turbine shaft front fulcrum bearing wear

A low-pressure turbine shaft and aero-engine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of passive troubleshooting, etc., and achieve the effect of reducing wear and tear, reducing wear probability, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

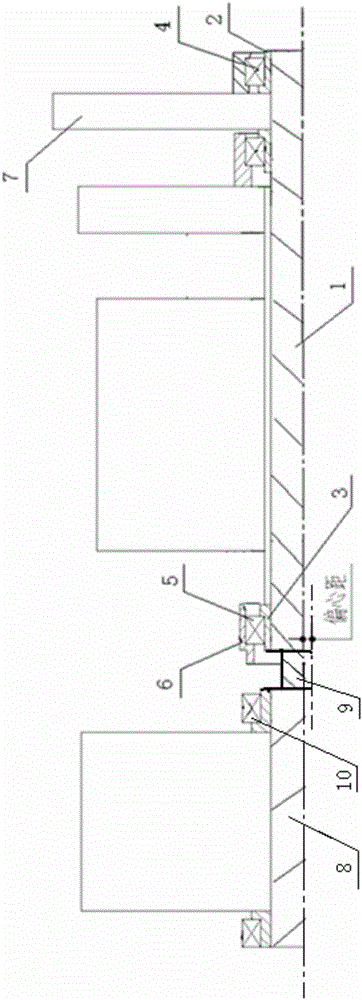

[0025] Such as figure 1 Shown, a kind of method that prevents aeroengine low-pressure turbine shaft front fulcrum bearing from wearing and tearing, comprises the steps:

[0026] (1) Detect and adjust the low-pressure turbine shaft 1. First, detect and adjust the end face runout and radial runout of the low-pressure turbine rear fulcrum bearing housing 2 to 0-0.01mm; then detect the end face runout and the radial runout of the front fulcrum bearing mounting surface 3 Whether the radial runout is 0-0.01mm, and the front fulcrum bearing installation surface 3 whose runout is out of tolerance is repaired with a high-precision grinder to ensure that the end surface runout and radial runout of the front fulcrum bearing installation surface 3 are 0-0.01mm, Thereby ensuring that the straightness of the low-pressure turbine shaft 1 meets the technical requirements;

[0027] (2) Detect and adjust the front fulcrum bearing installation surface 3 in the assembled state of the low-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com