Multi-joint bionic mechanical chela with autonomously-distributed power

A bionic machine, multi-joint technology, applied in the field of bionic robots, can solve the problems of single movement mode, inconvenient installation and maintenance, less freedom, etc., and achieve the effects of convenient installation and disassembly, improved work reliability, and reduced wear and tear failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

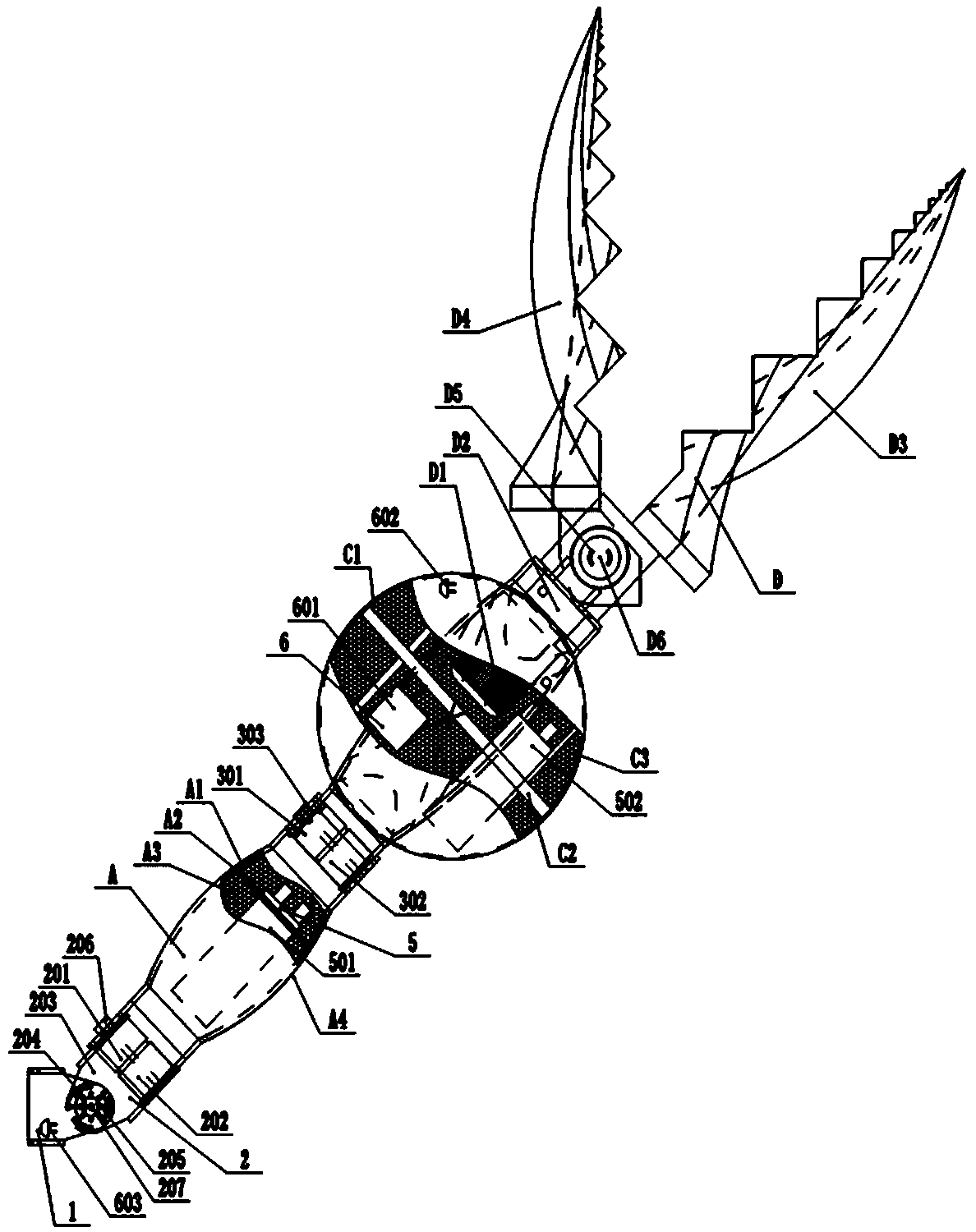

[0033] Reference figure 1 , figure 2 , This embodiment of the multi-joint bionic mechanical chelator with autonomously distributed power includes the connecting frame 1, the three-dimensional joint 2, the chelating section A, the two-dimensional joint I3, the chelating shield section C, the clamp section D, the power device 5, and the electric control device. 6; The three-dimensional joint 2 is fixed on the connecting frame 1 and connected to the chelating section A, the cheating section A is connected to the chelating shield section C through the two-dimensional joint Ⅰ3, and the clamp section D is fixed to the chelating shield section C. The power unit 5 includes a battery pack 501 and battery pack Ⅱ502 are respectively fixed in the cavity of chelating section A and chelating shield section C. The electric control device 6 is fixed in the cavity of chelating shield section C. The electric control device 6 is connected to the power device 5 and the three-dimensional joint 2 res...

Embodiment 2

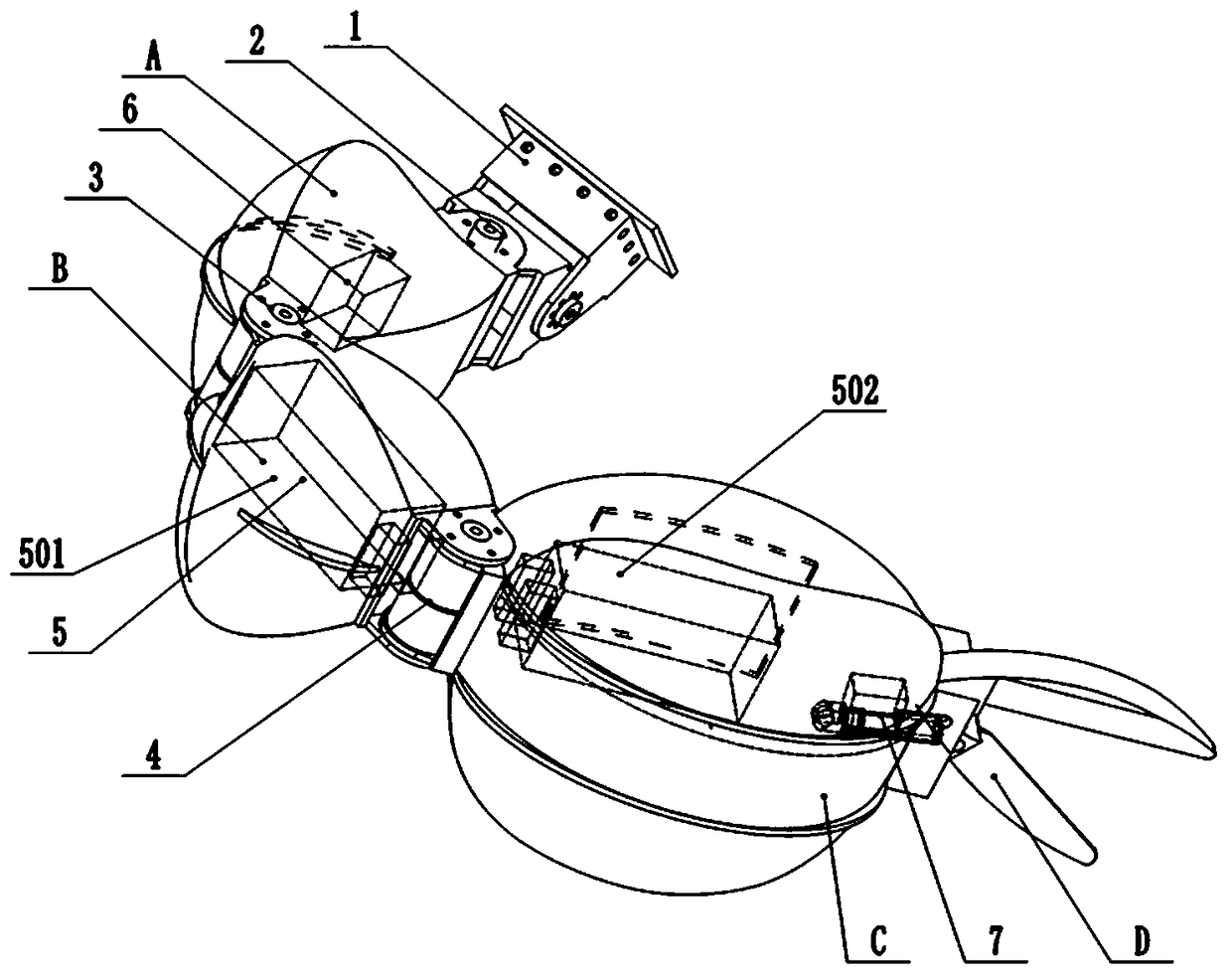

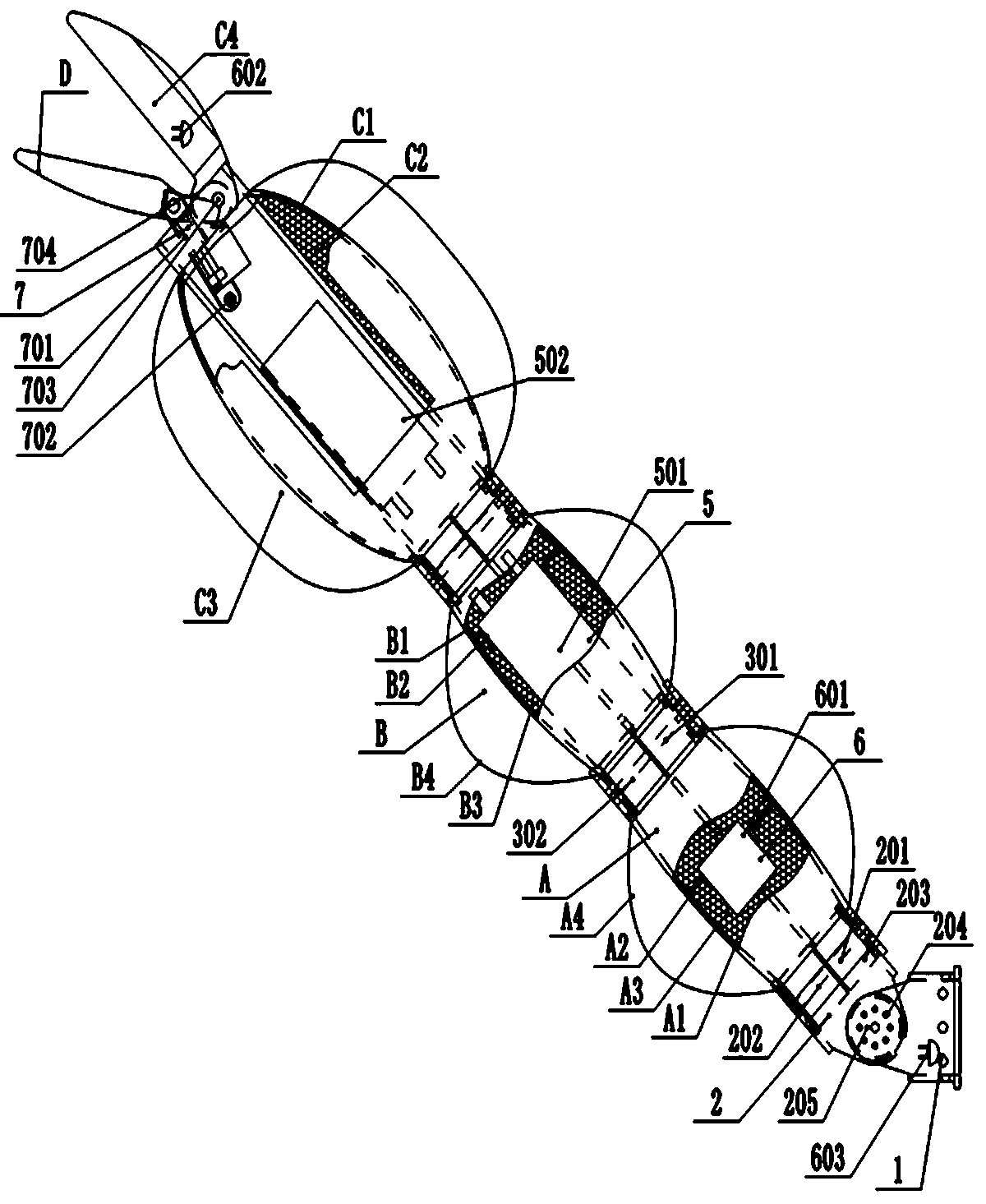

[0039] Reference image 3 , Figure 4 , This embodiment of the multi-joint bionic mechanical chelating forceps with autonomously distributed power includes the connecting frame 1, the three-dimensional joint 2, the chelating section A, the two-dimensional joint Ⅰ3, the chelating section B, the two-dimensional joint II4, the chelating shield section C, and the clamp movement. Mechanism 7, forceps section D, power device 5, electric control device 6; three-dimensional joint 2 is fixed on the connecting frame 1 and connected to the chelating section A, which is connected to the chelating section B through the two-dimensional joint I3, and the cheating section B passes through The two-dimensional joint Ⅱ 4 is connected to the chelating shield section C, and the chelating shield section C is connected to the clamp section D through the clamping mechanism 7. The power unit 5 mainly includes the battery pack I 501 and the battery pack Ⅱ 502, which are respectively fixed to the chelating...

Embodiment 3

[0046] Reference Figure 5 , Image 6 , Figure 7 The difference between the multi-joint bionic mechanical pliers with autonomously distributed power in this embodiment and the second embodiment is that: the mechanical pliers is additionally equipped with a swing saw 8, which is fixed on the upper middle of the chelating shield section C; the swing saw 8 includes a drive Motor 801, swing saw blade 802; the clamp section D adopts a sawtooth jaw; the charging port 602 adopts a wireless induction charging port, the electrical plug-in 603 adopts wireless Bluetooth for communication, and the reducer adopts a multi-stage In the planetary reducer, the driving motor adopts a stepping motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com