Heat exchange core plate, total heat exchange module, air interchanger and air conditioner

A technology of full heat exchange and ventilation device, which is applied in the field of heat exchange core board, ventilation device, air conditioner, and full heat exchange module, and can solve the problems of short heat exchange time and low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

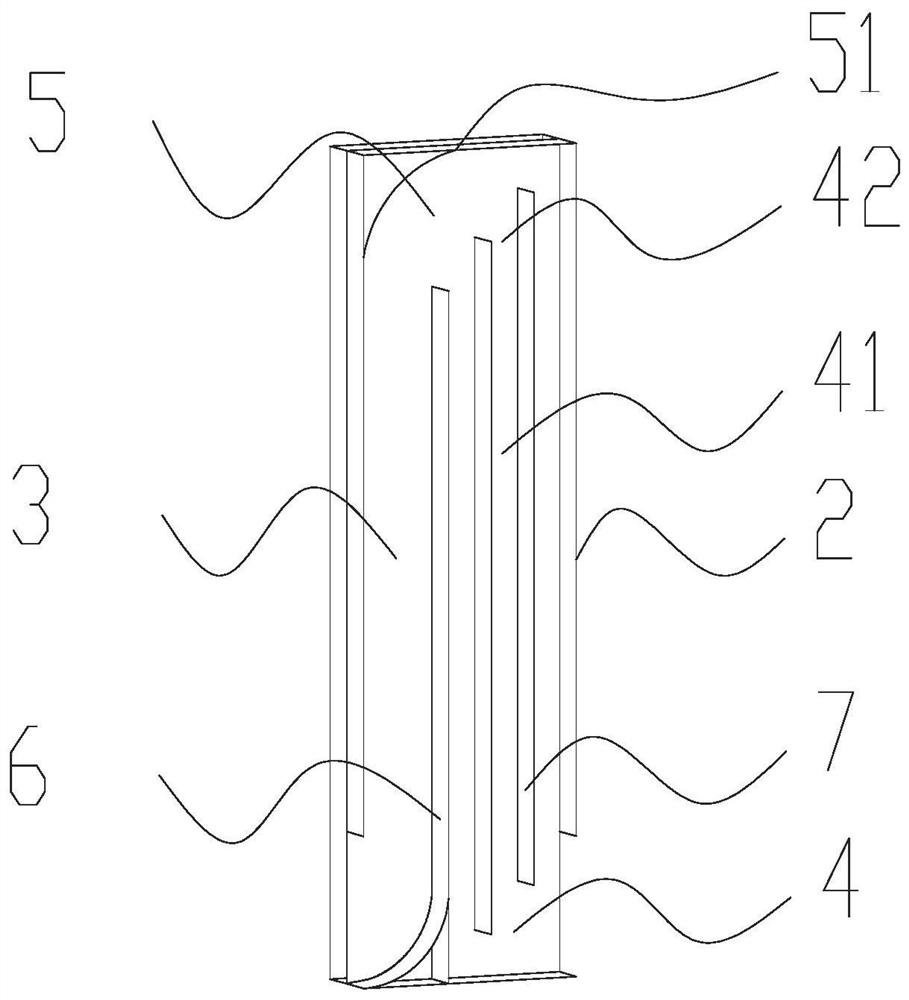

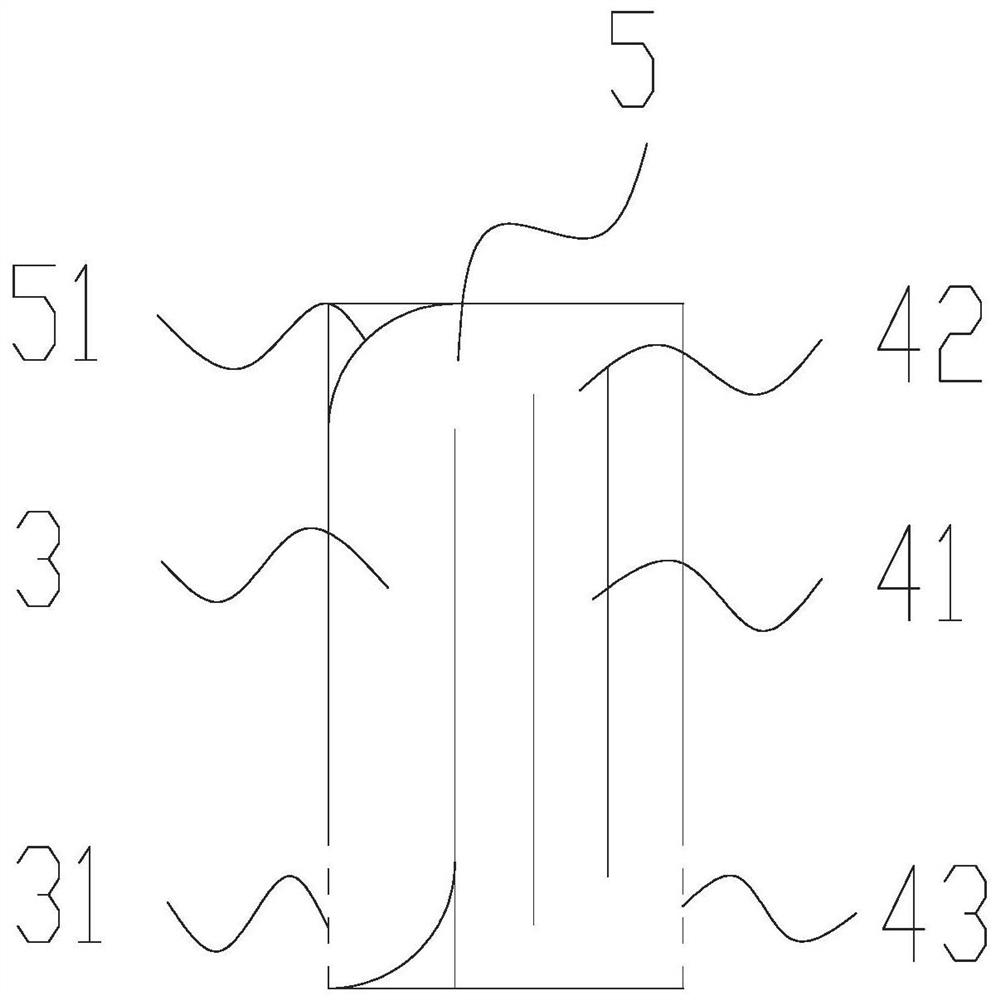

[0037] This embodiment provides a heat exchange core plate. Flow channels are formed on one side of the heat exchange core plate. The flow channels include a first flow channel in the first flow direction, a second flow channel in the second flow direction, and a flow channel connected to the first flow channel and the turning channel between the second flow channel; the outer guide edge of the turning channel is formed with an inclined guide surface, and the inclined guide surface extends from the first flow channel side to the second flow channel side; and in the second flow channel A plurality of parallel sub-channels are formed, and each sub-channel is formed at the end close to / connected with the diversion channel to communicate with the diversion channel, and the flow channel communication port is for the fluid flowing through the heat exchange core plate to flow in or out The connection structure; specifically, the flow channel communication openings of the multiple para...

Embodiment 2

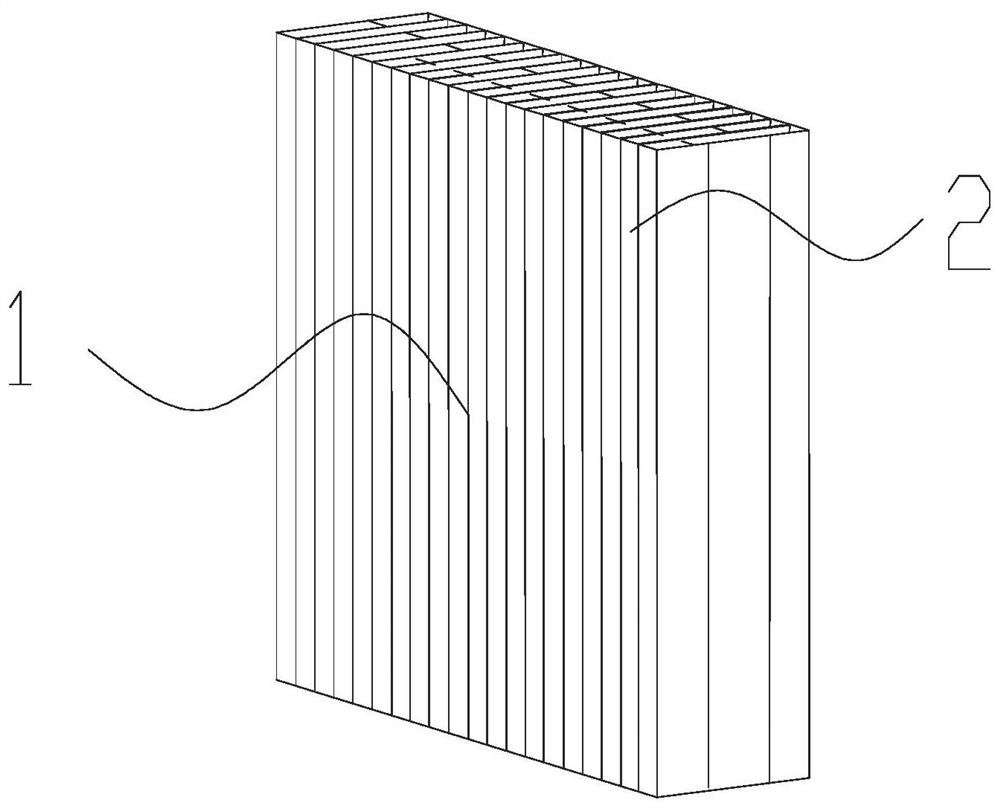

[0045] This embodiment provides a heat exchange core plate. Specifically, the heat exchange core plate has a mirror-symmetrical structure with the heat exchange core plate described in Embodiment 1, and further has a mirror-image symmetrical flow structure with the heat exchange core plate in the embodiment. road structure. By forming a mirror-image symmetrical arrangement with the heat exchange core plate of Example 1, a heat exchange core plate structure similar to but not identical to that of Example 1 is formed; further, the heat exchange core plate in the embodiment The plates are alternately stacked with the heat exchange core plates in this embodiment to form a total heat exchange module. Specifically, the first flow passages of the multiple heat exchange core plates are arranged on the same side of the total heat exchange module; the second flow passages of the multiple heat exchange core plates are arranged on the same side of the total heat exchange module.

[0046]...

Embodiment 3

[0053] This embodiment provides a total heat exchange and ventilation device, the total heat exchange and ventilation device is equipped with the heat exchange core plate described in embodiment 1 or the total heat exchange module described in embodiment 2; further optimized, when the total heat exchange When the heat exchange and ventilation device is equipped with a total heat exchange module in which the heat exchange core plates alternately form the flow layer of the turbid air and the flow layer of the fresh air, the total heat exchange and ventilation device is also equipped with an indoor turbid air inlet duct, an indoor turbid air The wind outlet wind channel, the outdoor fresh air inlet air channel and the outdoor fresh air outlet air channel; the indoor turbid air flow inlet of the turbid wind flow layer is connected to the indoor turbid wind inlet air channel; the indoor turbid air flow outlet of the turbid wind flow layer is connected to the The indoor dirty air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com