On-line measurement system for inner diameter of large thin-walled workpiece

A technology of large thin-walled parts and thin-walled parts, which is applied in the field of parts processing, can solve problems such as large errors, and achieve the effect of improving measurement accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

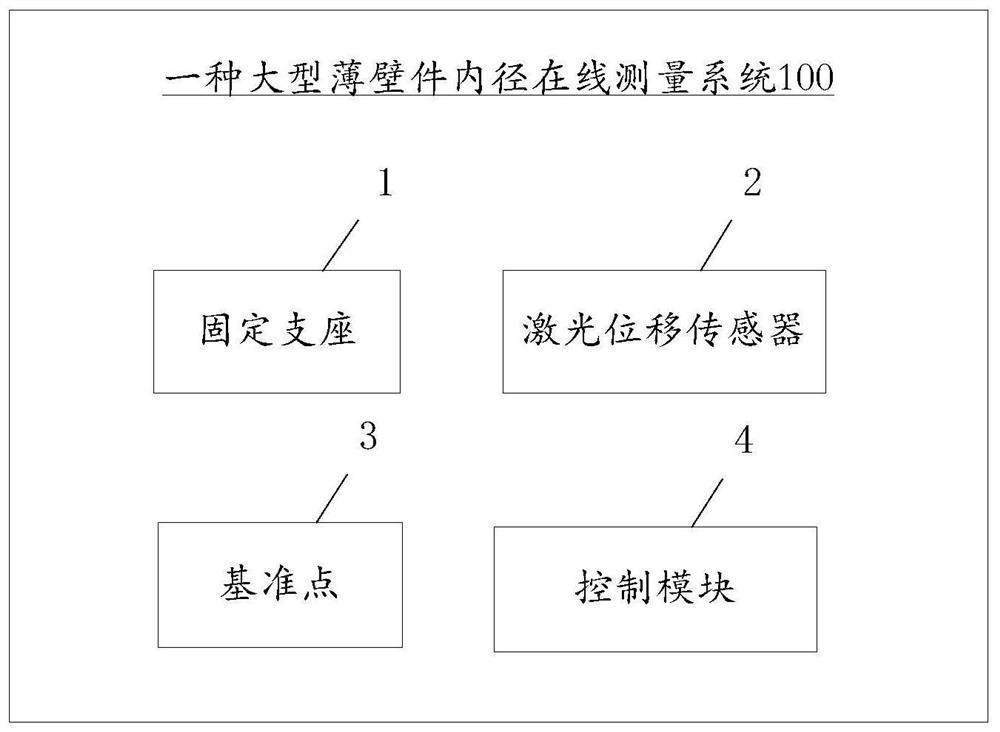

[0053] Such as figure 1 As shown, this embodiment provides an online measurement system 100 for the inner diameter of a large thin-walled part, including: a fixed support 1 , a laser displacement sensor 2 , a reference point 3 and a control module 4 .

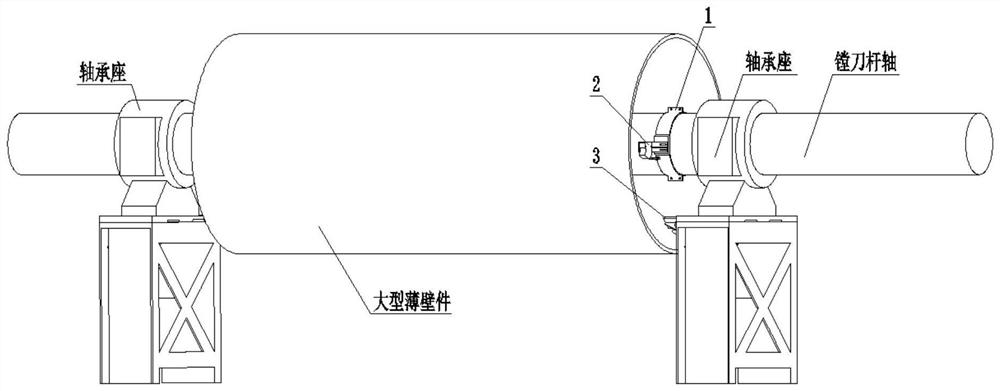

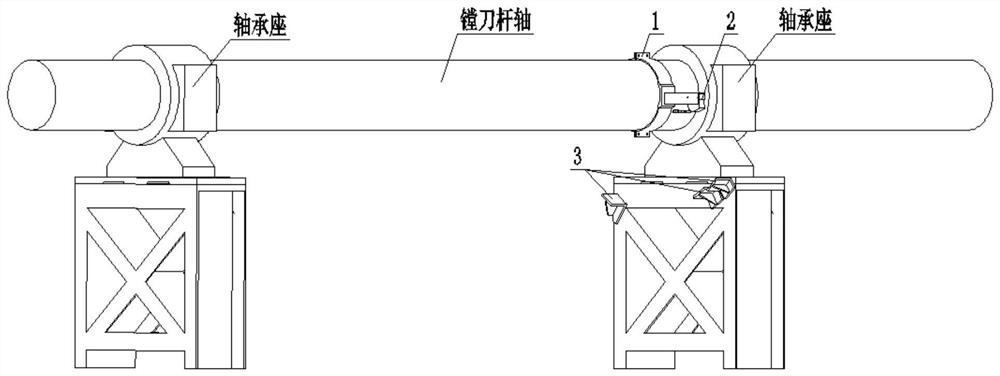

[0054] further, such as Figure 2-4 As shown, the assembly method of the measurement system 100 is as follows:

[0055] The fixed support 1 is arranged on the boring bar shaft of the special boring machine, wherein the thin-walled part to be measured is placed on the special boring machine;

[0056] The laser displacement sensor 2, the rear end of the laser displacement sensor 2 is fixed on the fixed support 1, the front end of the laser displacement sensor 2 is provided with a sensor head, and the laser displacement sensor 2 is located in the thin-walled part;

[0057] The control module 4 is connected with the laser sensor 2, and the control module 4 is used to: control the laser displacement sensor 2 to measure the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com