Chemical dosing system for main steam humidity test and using method thereof

A technology of humidity test and dosing system, applied in the field of main steam system, can solve the problem that chemical tracer is not suitable for dosing device to measure the humidity of main steam, and achieve the effect of eliminating influence and accurate measurement and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

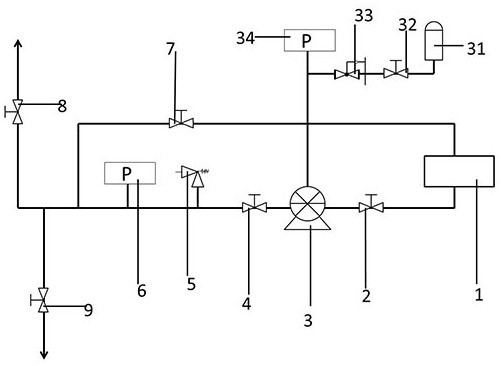

[0035] A chemical dosing system for the main steam humidity test, the chemical dosing system for the main steam humidity test includes a self-circulating closed pipeline, a dosing pipeline, and a sewage pipeline, wherein the self-circulating closed pipeline includes sequentially connected dosing boxes 1. Dosing box outlet isolation valve 2, pneumatic pump 3, pump outlet isolation valve 4, safety valve 5, pressure gauge behind the pump 6, self-circulation isolation valve 7, wherein the pneumatic pump 3 is connected to the high-pressure cylinder 31 through a pipeline , and between the high-pressure gas cylinder 31 and the pneumatic pump 3, a gas cylinder outlet isolation valve 32, a pressure reducing valve 33, and a pressure gauge 34 before the pump are arranged in sequence; Between the self-circulation isolation valve 7 and the pressure gauge 6 behind the pump, a drug addition isolation valve 8 is provided on the drug addition pipeline, and a sewage discharge isolation valve 9 i...

Embodiment 2

[0037] A chemical dosing system for the main steam humidity test, the chemical dosing system for the main steam humidity test includes a self-circulating closed pipeline, a dosing pipeline, and a sewage pipeline, wherein the self-circulating closed pipeline includes sequentially connected dosing boxes 1. Dosing box outlet isolation valve 2, pneumatic pump 3, pump outlet isolation valve 4, safety valve 5, pressure gauge behind the pump 6, self-circulation isolation valve 7, wherein the pneumatic pump 3 is connected to the high-pressure cylinder 31 through a pipeline , and between the high-pressure gas cylinder 31 and the pneumatic pump 3, a gas cylinder outlet isolation valve 32, a pressure reducing valve 33, and a pressure gauge 34 before the pump are arranged in sequence; Between the self-circulation isolation valve 7 and the pressure gauge 6 behind the pump, a drug addition isolation valve 8 is provided on the drug addition pipeline, and a sewage discharge isolation valve 9 i...

Embodiment 3

[0039] A method for using a chemical dosing system for a main steam humidity test, comprising the following steps:

[0040] (1) Flushing before dosing: inject desalinated water into the dosing box 1, and the sewage pipeline is connected to the sewage tank; open the outlet isolation valve 2 of the dosing box, the pump outlet isolation valve 4, and the self-circulation isolation valve 7, and close the sewage isolation Valve 9, dosing isolation valve 8, adjust the air pressure of the high-pressure gas cylinder 31 so that the gauge pressure of the pressure gauge in front of the pump is 0.30 MPa, start the pneumatic pump 3 for self-circulation; after 3 minutes of circulation, open the sewage isolation valve 9, and close the self-circulation isolation valve 7; repeat the above operation 3 times, shut down the pneumatic pump;

[0041] (2) Dosing operation: connect the dosing pipeline to the dosing point, open the upstream valve of the main steam system; add tracer and 10L desalted wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com