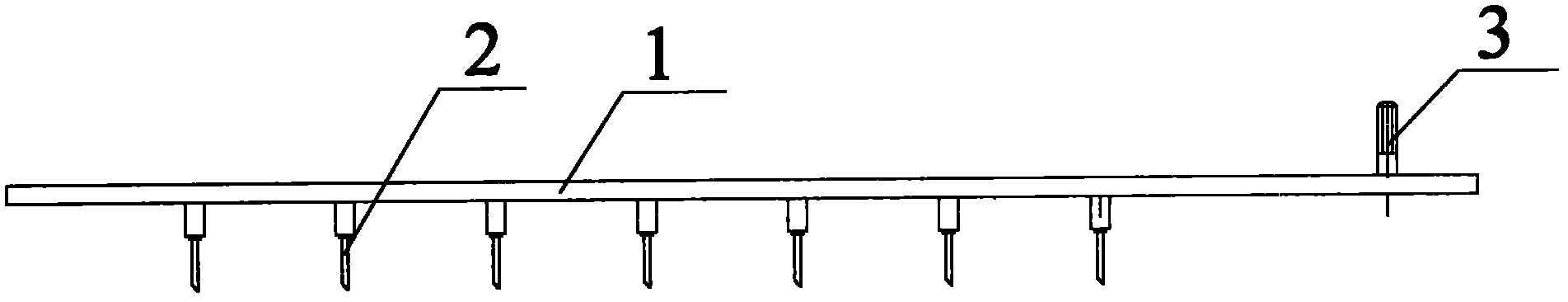

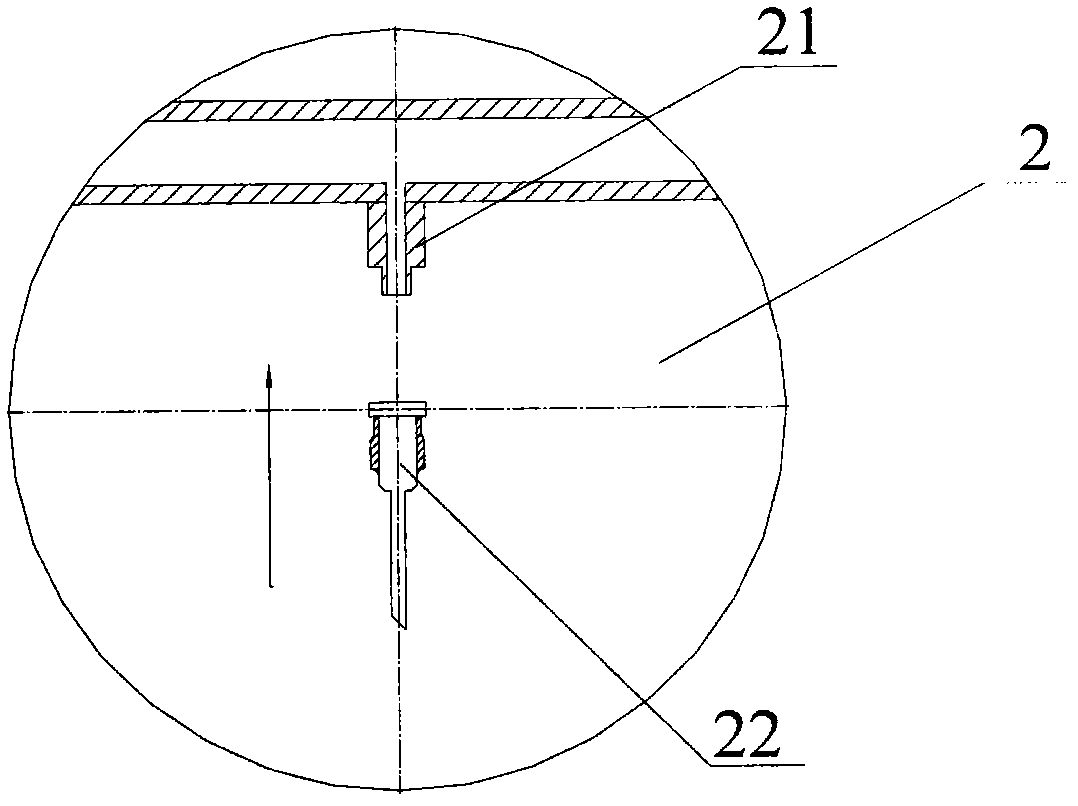

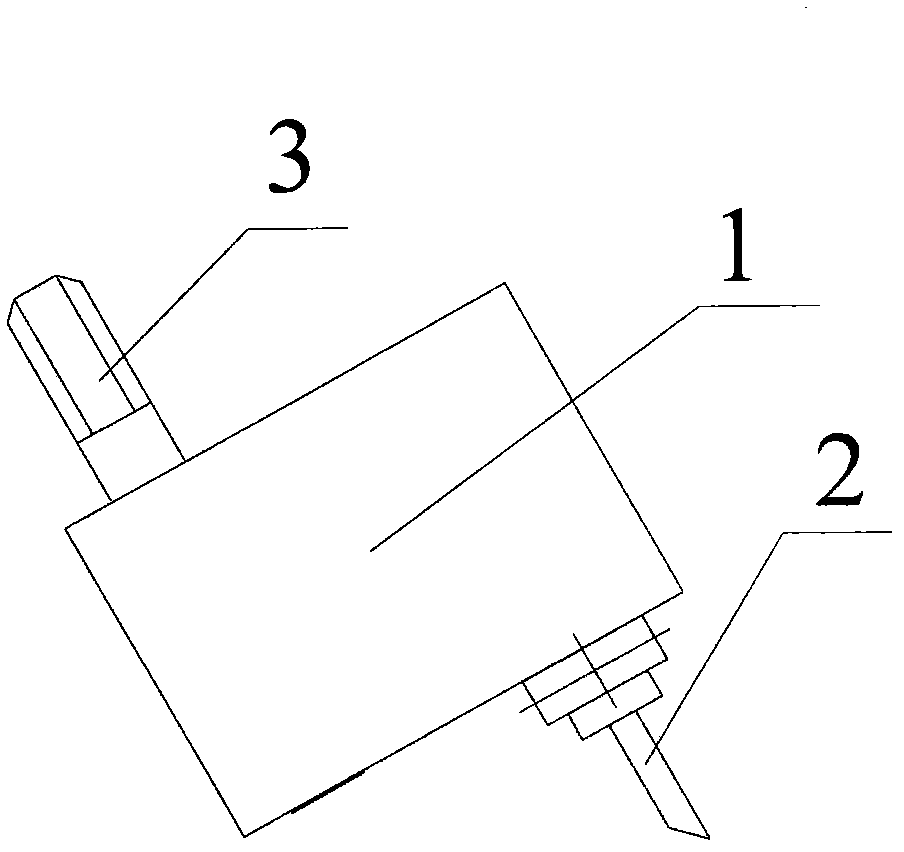

Spraying type water injection device and water injection type double mirror jointing method

A water injection equipment and spray technology, which is applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of not bright enough color, not clear texture, and no water penetration on the surface, so as to achieve simple design and color. Vivid, surface effect water-permeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Double mirror blank

[0043]1. The first surface layer: the slurry prepared according to the first surface layer slurry in Table 1, with AR-80 paper as the carrier, the viscosity of the slurry is controlled between 2500-3000CPS, the coating thickness is 0.18mm, and then enters the drying process. Drying in the dry area, the drying temperature is divided into four sections, namely 80°C, 90°C, 95°C and 100°C, each section is 4m long, and the vehicle speed is 5.5-6m / min

[0044] 2. Middle layer: apply the middle layer slurry prepared according to Table 1 on the dried first surface layer slurry, the slurry viscosity is controlled between 7000-8000CPS, the coating thickness is 0.25mm, and then enters the drying area For drying, the drying temperature is divided into four sections, namely 70°C, 85°C, 100°C and 115°C, each section is 4m long, and the vehicle speed is 5.5-6m / min.

[0045] 3. The first bonding layer: apply the first bonding layer slurry prepared according to...

Embodiment 2

[0053] 1. Double mirror blank

[0054] 1. The first surface layer: the slurry prepared according to the first surface layer slurry in Table 1, with AR-80 paper as the carrier, the viscosity of the slurry is controlled between 2500-3000CPS, the coating thickness is 0.18mm, and then enters the drying process. Drying in the dry area, the drying temperature is divided into four sections, namely 80°C, 90°C, 95°C and 100°C, each section is 4m long, and the vehicle speed is 5.5-6m / min

[0055] 2. Middle layer: apply the middle layer slurry prepared according to Table 1 on the dried first surface layer slurry, the slurry viscosity is controlled between 7000-8000CPS, the coating thickness is 0.25mm, and then enters the drying area For drying, the drying temperature is divided into four sections, namely 70°C, 85°C, 100°C and 115°C, each section is 4m long, and the vehicle speed is 5.5-6m / min.

[0056] 3. The first adhesive layer: apply the first adhesive layer slurry prepared according...

Embodiment 3

[0064] 1. Double mirror blank

[0065] 1. The first surface layer: the slurry prepared according to the first surface layer slurry in Table 1, with AR-80 paper as the carrier, the viscosity of the slurry is controlled between 2500-3000CPS, the coating thickness is 0.18mm, and then enters the drying process. Drying in the dry area, the drying temperature is divided into four sections, namely 80°C, 90°C, 95°C and 100°C, each section is 4m long, and the vehicle speed is 5.5-6m / min

[0066] 2. Middle layer: apply the middle layer slurry prepared according to Table 1 on the dried first surface layer slurry, the slurry viscosity is controlled between 7000-8000CPS, the coating thickness is 0.25mm, and then enters the drying area For drying, the drying temperature is divided into four sections, namely 70°C, 85°C, 100°C and 115°C, each section is 4m long, and the vehicle speed is 5.5-6m / min.

[0067] 3. The first adhesive layer: apply the first adhesive layer slurry prepared according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com