Oil field block overall profile adjusting device and adjusting method

An adjustment method and technology for adjusting devices, which are applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of high safety risk, many measures, and long well occupation time, and achieve the effect of less corrosiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

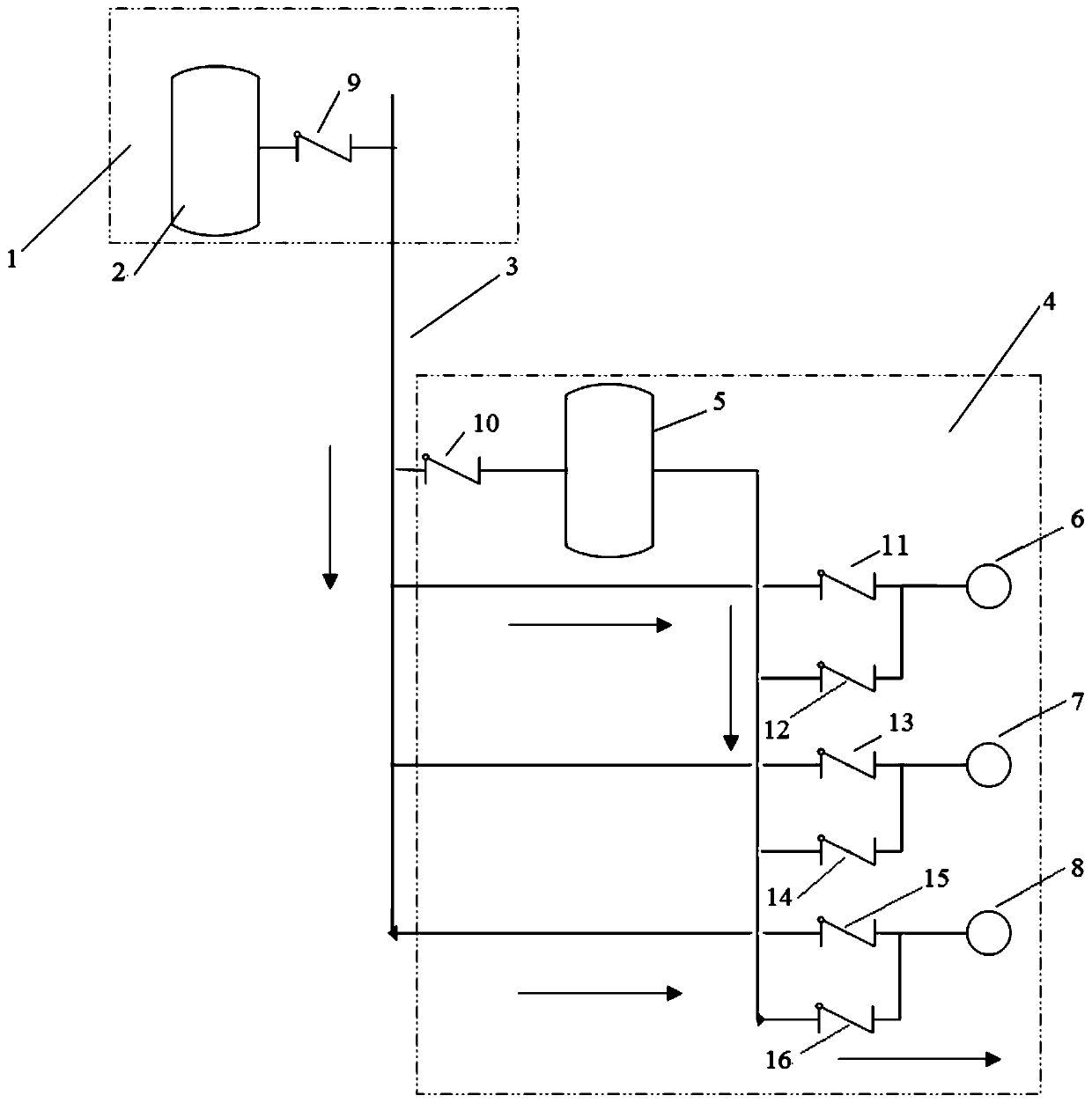

[0051] refer to figure 1 , taking a certain block of Jiyuan Oilfield as an example, due to the influence of reservoir heterogeneity and fracture development, the water absorption status of some wells gradually deteriorated, and the proportion of wells with uneven water absorption increased year by year, accounting for nearly 50% at present. Contradictions gradually became prominent, the form of water absorption became worse, and the contradictions in development were gradually exposed. In order to improve the development effect of this block, it is planned to carry out the overall profile adjustment operation of 31 water injection wells with uneven water absorption in this block, and remove the plugging wells in the stratum. Dispensing volume. The diversion acidizing well is mainly determined by observing the water absorption profile, the water injection volume and water absorption degree of different layers. Among them, 15 wells are used for acidizing and plugging removal o...

Embodiment 2

[0058] For the 16 injection wells that require diversion acidification, to figure 1 Take the second water injection well 7 as an example. Under normal water injection conditions, the first dosing device 2 (also called plugging removal equipment) of the water injection station and the second dosing device 5 (also called temporary plugging equipment) of the well site are required. ). First open the second check valve 10 and the sixth check valve 14 to allow the diversion agent to enter the hypertonic zone of the second water injection well 7; 15 parts of surfactant, 10 parts of dispersant and 40 parts of organic solvent. When the amount of diverting agent is , close the second check valve 10 and the sixth check valve 14, and then open the first check valve 9 and the fifth check valve 13, so that the neutral plug-removing agent and the flow-diverting agent can merge to form a blocking barrier, so that the following The neutral plugging removal agent turns to enter the low per...

Embodiment 3

[0062] The situation and steps of this embodiment are the same as those of Embodiment 2, except that the specific components of all neutral plug-removing agents and diverting agents are different.

[0063] Wherein, the diverting agent entering the hypertonic zone of the second water injection well 7 includes 35 parts of thermosetting resin, 7.5 parts of polyol, 12.5 parts of surfactant, 7.5 parts of dispersant and 35 parts of organic solvent in parts by weight.

[0064] When the hypertonic zone is clogged, the first check valve 9 and the fifth check valve 13 are first opened to allow the neutral plugging agent to enter the hypertonic zone. The neutral plugging agent used at this time consists of the following parts by weight: Material composition: 35 parts of biological enzyme, 7.5 parts of suspending agent, 7 parts of oxidizing agent, 12.5 parts of corrosion inhibitor, 7.5 parts of penetrating agent, 25 parts of chelating agent and 7.5 parts of surfactant.

[0065] Wherein, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com