Rectifying system and method for X-ray intensifier

An X-ray and intensifier technology, applied in the field of image processing, can solve problems such as high computational complexity, decreased corner point accuracy, and inability to extract feature points, achieving accurate measurement and calculation and low distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

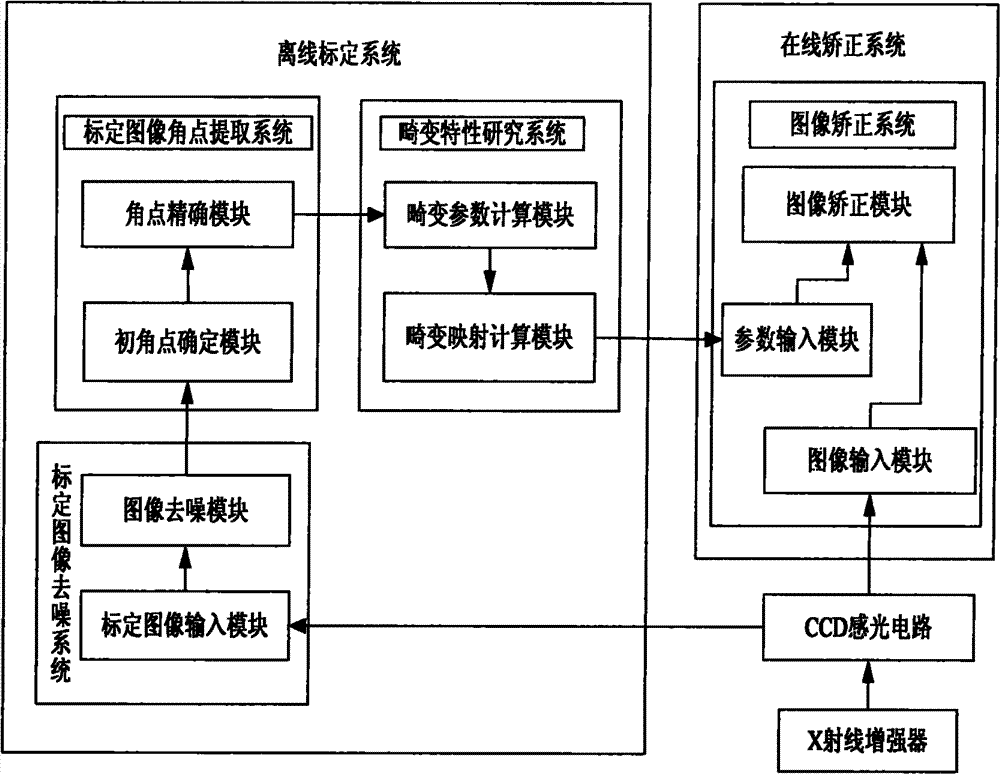

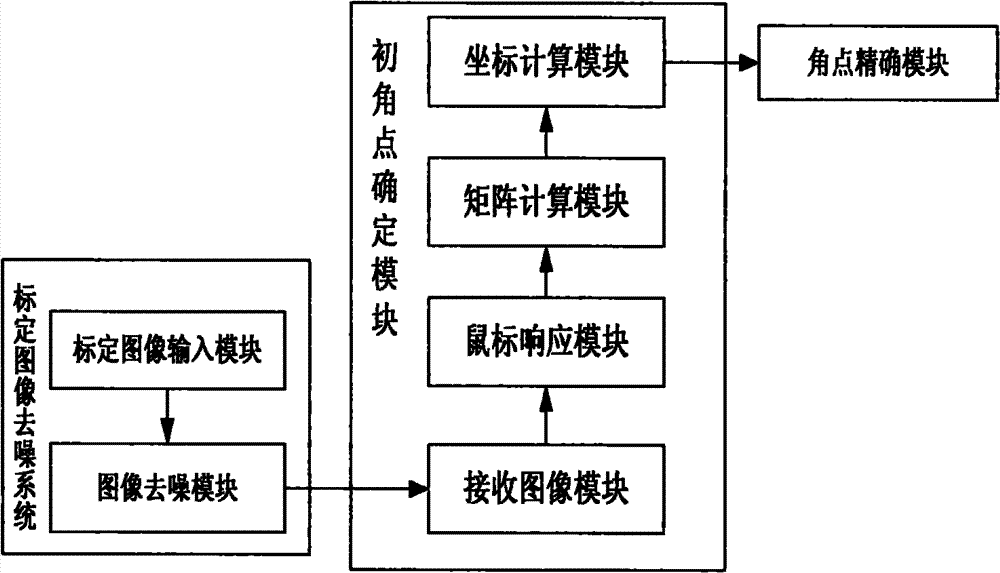

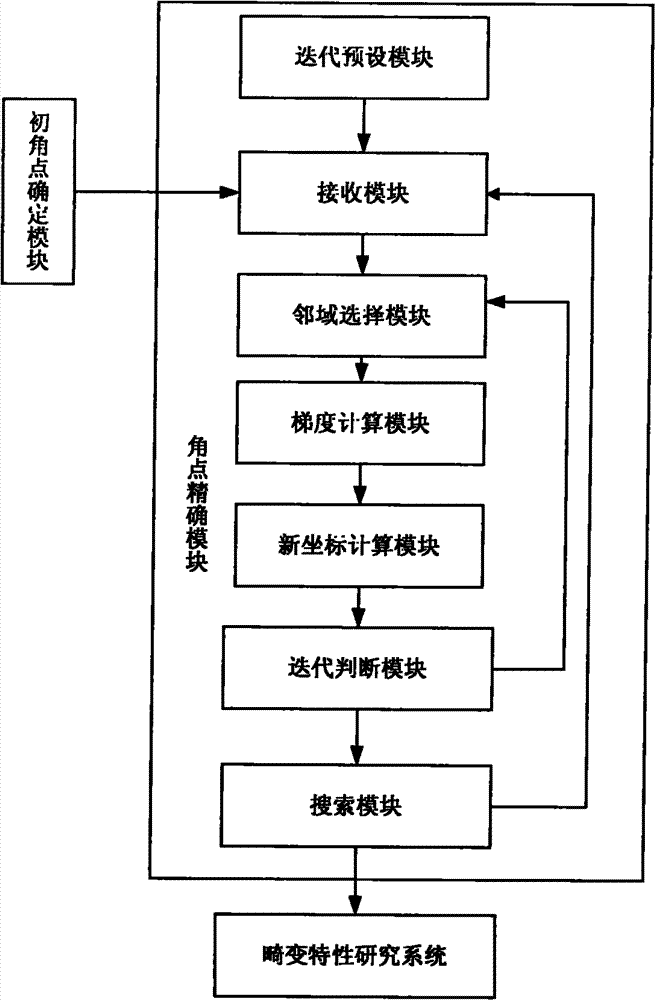

[0058] Such as figure 1 As shown, the X-ray intensifier correction system includes an X-ray source, an X-ray intensifier, a CCD photosensitive circuit and a control computer sequentially connected by an optical path. The control computer is provided with an offline calibration system and an online correction system. The offline calibration The system includes a calibration image denoising system, a calibration image corner extraction system and a distortion characteristic research system connected in sequence, the CCD photosensitive circuit is connected with the calibration image denoising system, the distortion characteristic research system is connected with an online correction system, and the The online correction system is connected to the CCD photosensitive circuit; a special calibration plate or a product under test is also placed between the X-ray source and the X-ray intensifier to connect with its optical path. When performing offline calibration through an offline c...

Embodiment 2

[0095] Other features of this embodiment are the same as embodiment 1 except the following features:

[0096] In the step (1-3-1), the several frames of calibration images are 25 frames of calibration images;

[0097] In the step (1-6), the number of sheets is twenty;

[0098] In the step (1-4-2), the number of corner points is ten.

[0099] The special calibration plate is a checkerboard calibration plate made of several metal sheets arranged at intervals on the base plate. The metal sheet is a high-density metal sheet; the substrate is a low-density non-metallic glass plate.

Embodiment 3

[0101] Other features of this embodiment are the same as embodiment 1 except the following features:

[0102] The special calibration plate is a checkerboard calibration plate made of several metal sheets arranged at intervals on the base plate. The metal sheet is a high-density metal sheet; the substrate is a low-density non-metallic wood board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com