Weight and application thereof in determining demoulding time of paste

A technology of demoulding time and weights, which is applied in the field of weights and its application in judging the demoulding time of paste, can solve the problems of affecting filling quality and project progress, affecting project progress, large judgment errors, etc., and achieves improvement Work efficiency and accuracy, high accuracy rate, and the effect of eliminating judgment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

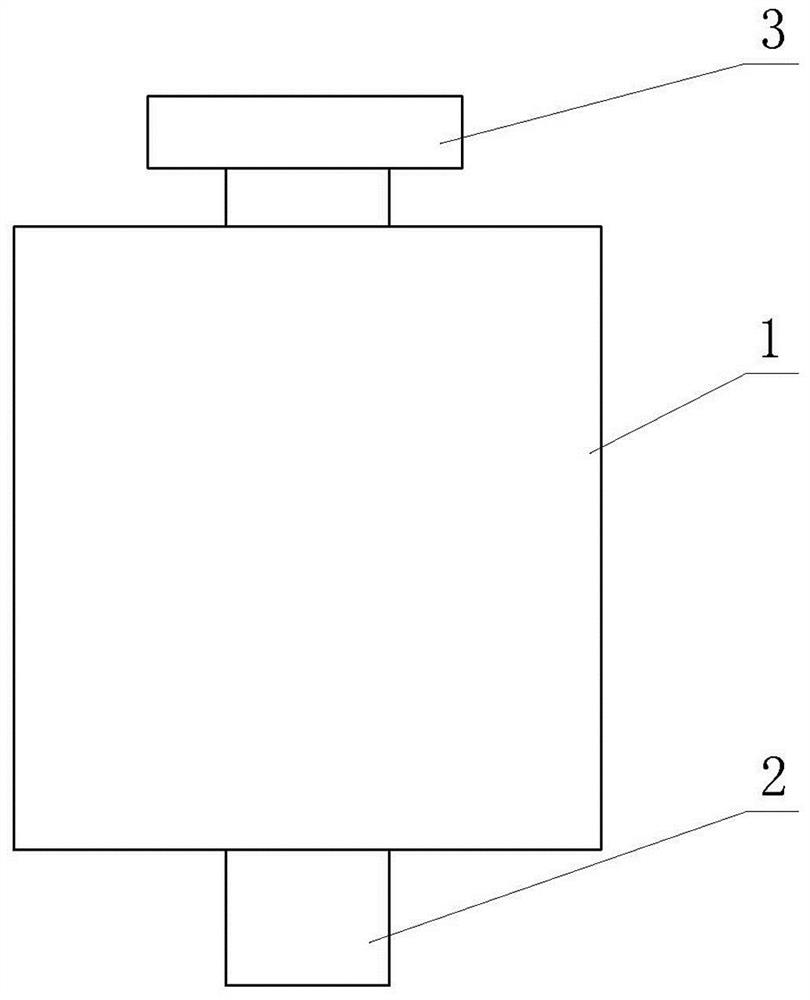

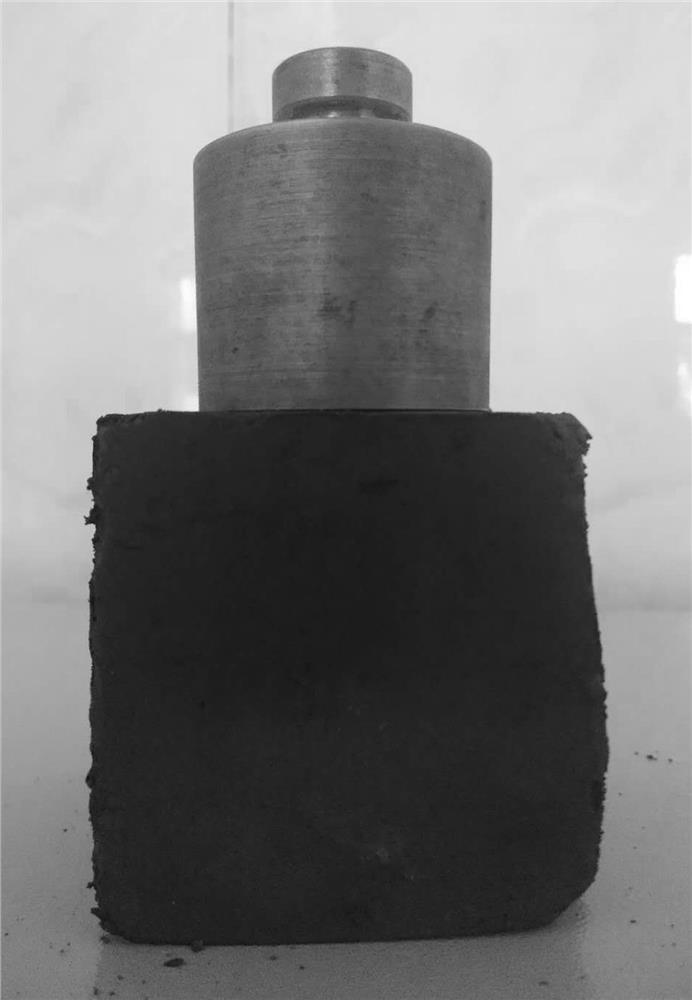

[0031] like figure 1 As shown, the weight of this embodiment includes a weight body 1 and a bump 2, the bump 2 is arranged at the bottom of the weight body 1 and protrudes outward from the weight body 1, and the bump 2 is set in a cylindrical shape , in addition, the cross-section of the bottom end of the bump is not limited to a circle, but can also be quincunx, square, rectangular, rhombus or irregular figure; the weight of the weight is set to 0.6 kg, and the surface area of the bottom end of the bump 2 Set to 1 square centimeter, and m / s=0.6.

[0032] The weight body 1 in this embodiment is configured as a cylinder, and it can also be configured as a cuboid or other shapes in other embodiments of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com