Damage identification method for constant cross-section beams based on horizontal support reaction force influence line difference

A support reaction force and damage identification technology, applied in the testing of machine/structural components, using stable tension/compression to test the strength of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

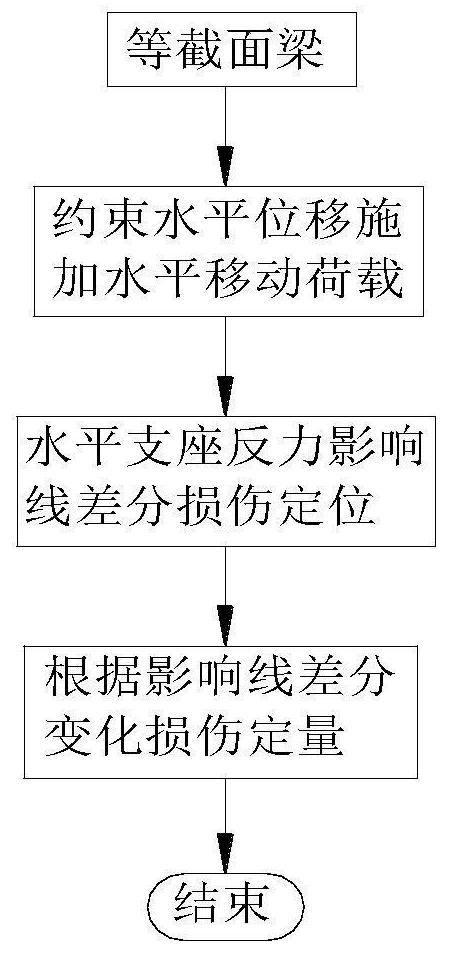

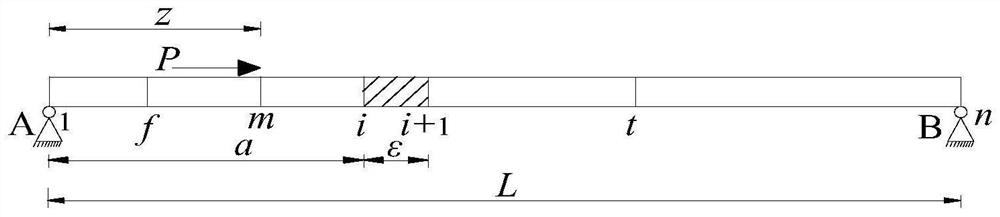

Method used

Image

Examples

Embodiment 1

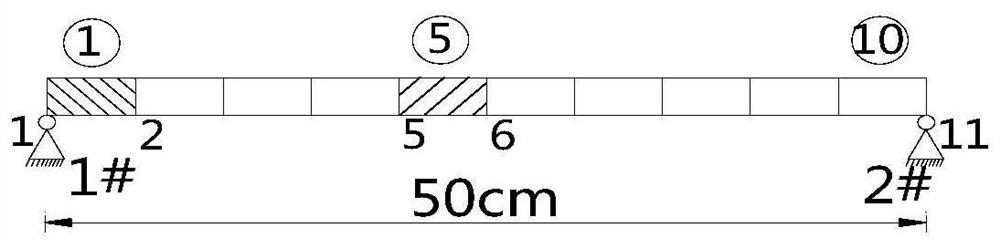

[0072] Embodiment one: see image 3 , the simply supported beam span is 50cm, 5cm divides a unit, a total of 10 units, 11 nodes, the number in the circle on the beam in the figure represents the unit number, the number below the beam is the node number, 1# and 2# represent two a stand. The cross-sectional size of the beam is b×h=6cm×3cm, and the elastic modulus of the material is 2.7×10 3 MPa, the density is 1200kg / m 3 .

[0073] In the actual bridge damage, the main manifestations are the corrosion and corrosion of steel bars and concrete materials and the appearance of cracks, resulting in a decrease in the elastic modulus of the bridge, but the cross-sectional area and weight of the bridge have not changed much. Therefore, in the finite element software simulation, the damage part adopts the simulation method of reducing the elastic modulus. The beam structure model is established by finite element software. Taking the damage condition of a single unit and multiple uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com