Packaging product defect detection equipment based on machine vision

A technology for product defects and detection equipment, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems of product missed inspection, increase the defective rate of product packaging, etc., and achieve the effect of reducing the defective rate and flexible shooting angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

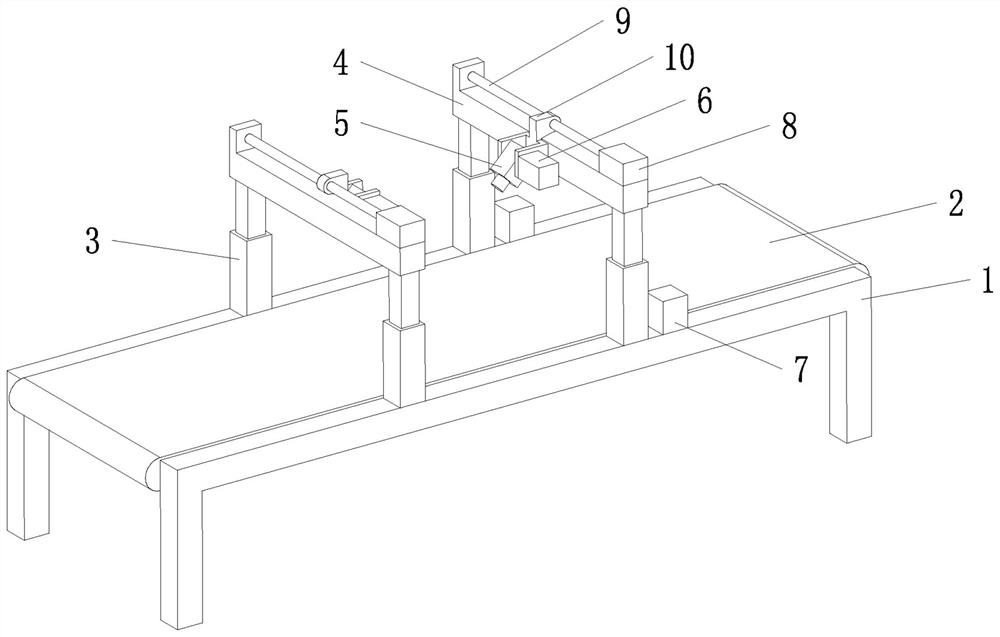

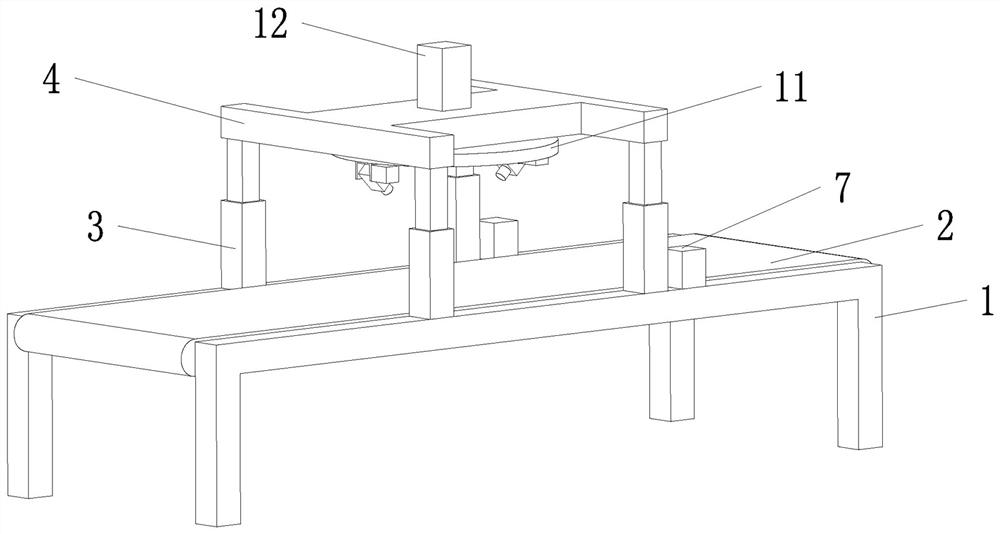

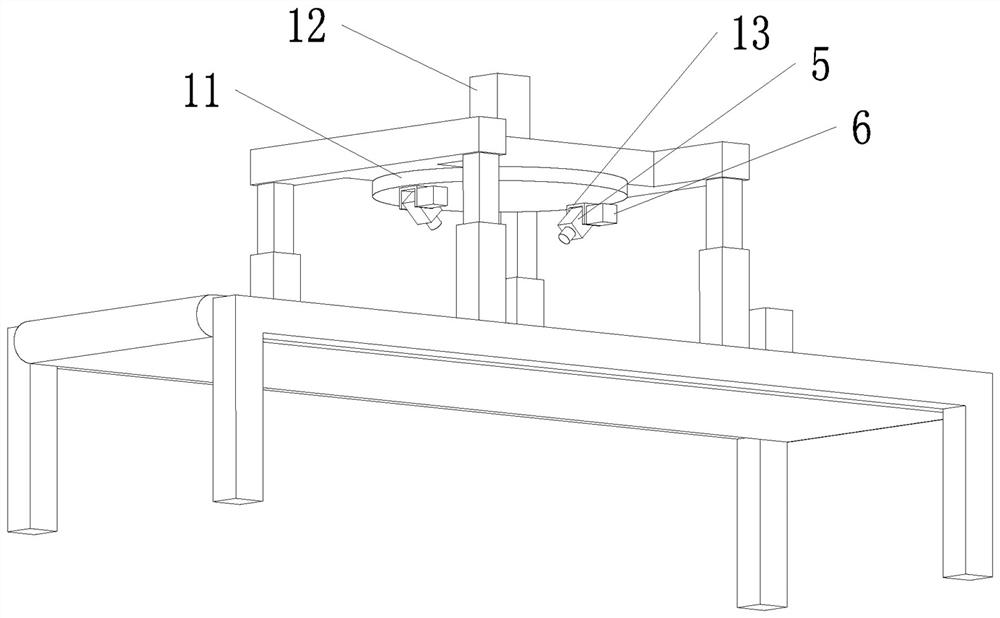

[0016] refer to Figure 1 to Figure 3 , a packaging product defect detection device based on machine vision, comprising a frame 1, a controller, the controller is provided with a memory, an image processing unit, a comparison unit, the frame 1 is provided with a conveyor belt 2, the transmission belt 2 Used to drive the target product, as long as it is a boxed or packaged product, lifting rods 3 are installed on both sides of the conveyor belt 2, and a camera bracket 4 is installed on the top of the lifting rod 3, and a detection device is installed on the camera bracket 4. Camera 5, the detection camera 5 is equipped with a reduction motor 6 for adjusting the shooting angle, an induction grating 7 is installed symmetrically on both sides of one end of the conveyor belt 2, the transmission belt 2, lifting rod 3, detection camera 5, reduction motor 6. The induction grating 7 is electrically connected to the controller. When the product package is conveyed on the conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com