Auxiliary pressure-dividing cable trench

A cable trench and voltage dividing technology, which is applied in the installation of cables, ground cables, electrical components, etc., can solve the problems of structural deformation of the cover plate and reduction of the strength of the cover plate, so as to prolong the service life, protect from damage, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

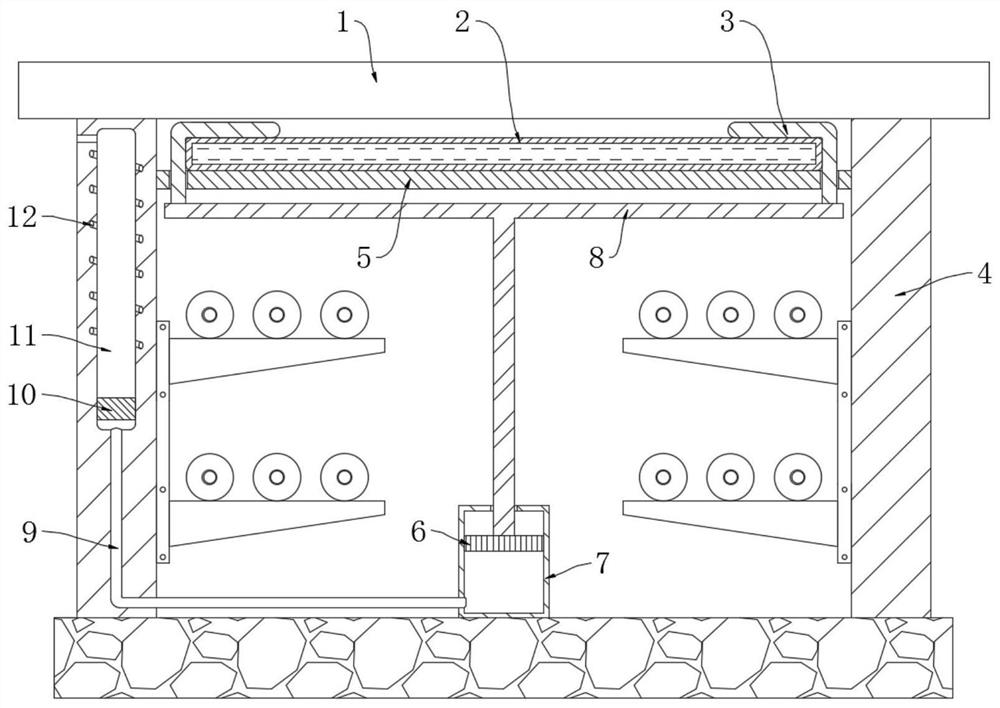

[0024] refer to figure 1 , an auxiliary pressure-dividing cable trench, including a trench body, a cover plate 1 and two side plates 4, a limit cylinder 7 is fixedly arranged in the trench body, and a sliding plate 6 is arranged for sealing and sliding in the limit cylinder 7, and on the slide plate 6 A T-shaped plate 8 is fixedly connected, and two L-shaped pressure plates 3 are symmetrically installed on the upper surface of the T-shaped plate 8, and a pressure dividing plate 5 is fixedly supported between the two side plates 4, and a capsule body 2 is placed on the pressure dividing plate 5. Both L-shaped pressing plates 3 include a horizontal section and a vertical section, the horizontal sections of the two L-shaped pressing plates 3 are located above the capsule body 2, and the vertical sections of each L-shaped pressing plate 3 slide through the dividing plate 5, wherein A trigger mechanism is also arranged in a side plate 4 .

[0025] In this embodiment, the trigger m...

Embodiment 2

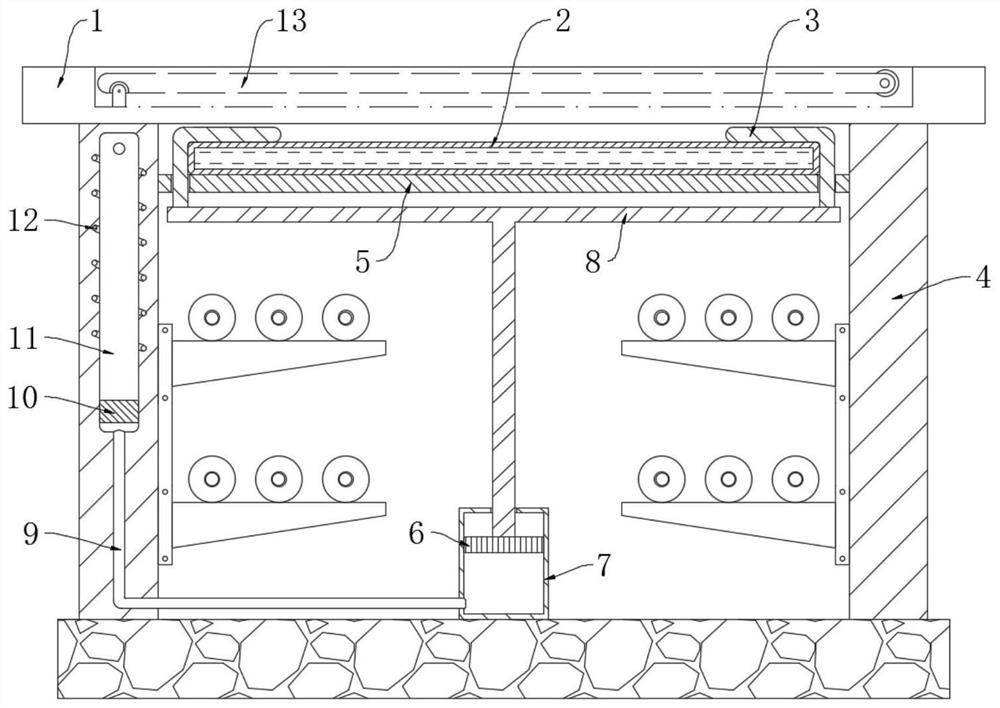

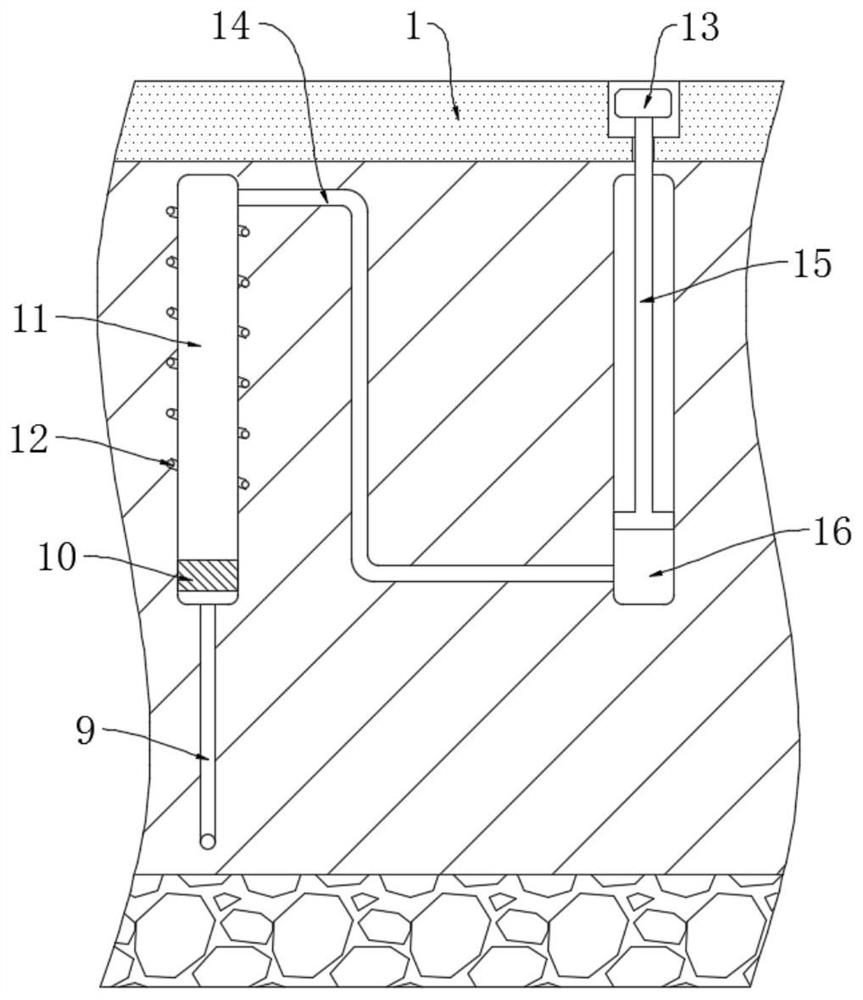

[0032] refer to Figure 2-5 The difference between this embodiment and Embodiment 1 is that a waterproof groove 16 is provided in the side plate 4, and a strut 15 is sealed and slidably installed in the waterproof groove 16, and the upper end of the strut 15 penetrates the corresponding side plate 4 and extends to On the top of the ditch body, the side wall of the cover plate 1 is connected with a gear rod 13 through the rotating shaft, and the end of the gear rod 13 away from the rotating shaft is slidably connected with the top of the pole 15, and the gear rod 13 is located on two adjacent cover plates 1 between, and the gear rod 13 is flush with the cover plate 1.

[0033] In this embodiment, a pressure-resistant pipe 14 communicates between the lower end of the waterproof groove 16 and the upper end of the vertical groove 11, and the pressure-resistant pipe 14 is a hard PVC pipe.

[0034] This embodiment can illustrate its functional principle through the following operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com