Asynchronous starting permanent magnet auxiliary type synchronous reluctance motor

A synchronous reluctance motor and permanent magnet technology, applied in synchronous machines, synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, etc., can solve high manufacturing costs, magnetic circuit design permanent magnets Problems such as installation obstruction and low saliency rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

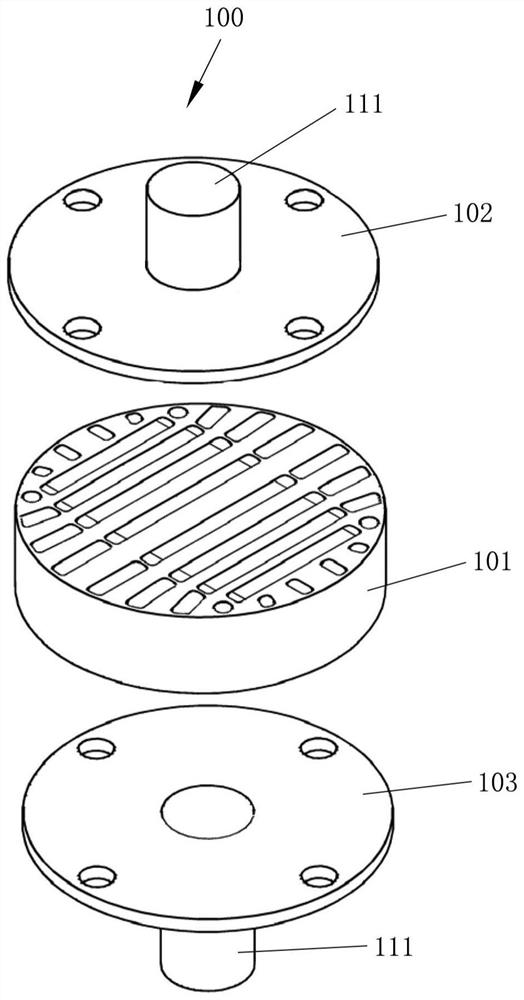

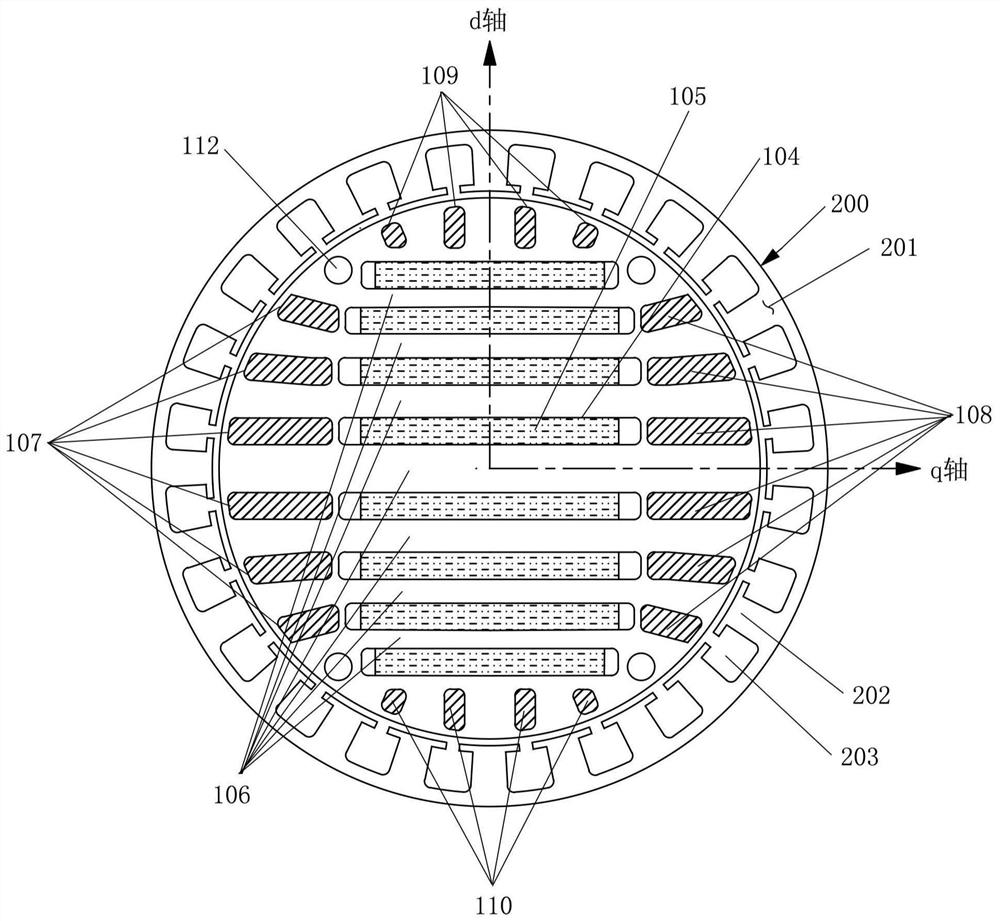

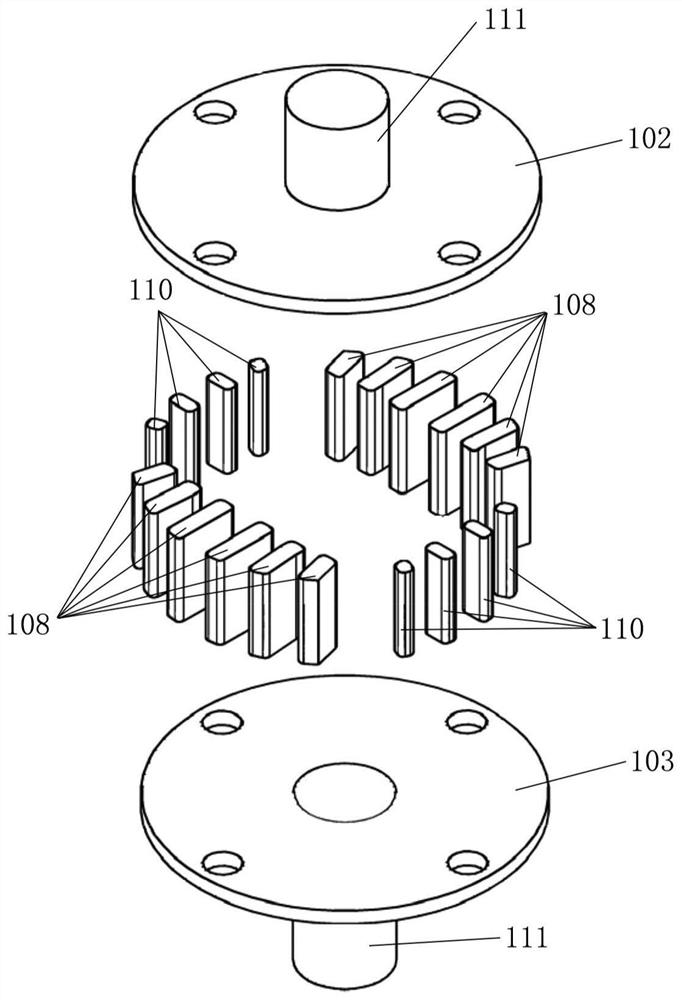

[0024] In order to solve the above-mentioned problems in the prior art, the present invention adopts a new motor rotor structure. In the new rotor structure, the through hole for installing the motor shaft on the rotor is removed, end covers are arranged at both ends of the rotor, the motor shaft is arranged on the end covers, and the motor shaft does not penetrate the rotor. This fundamentally solves the design difficulty of the permanent magnet synchronous reluctance motor, and can greatly increase the setting capacity of the permanent magnet.

[0025] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] figure 1 It is an exploded schematic view of the rotor assembly of the asynchronous start permanent magnet assisted synchronous reluctance motor according to the present invention, figure 2 is a radial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com