Power supply soft start circuit with hot plug function

A technology of soft start circuit and power supply, applied in the direction of output power conversion device, electrical components, etc., can solve the problem of damage to the switching tube of the system, achieve the protection of components, improve reliability and service life, and suppress surge current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

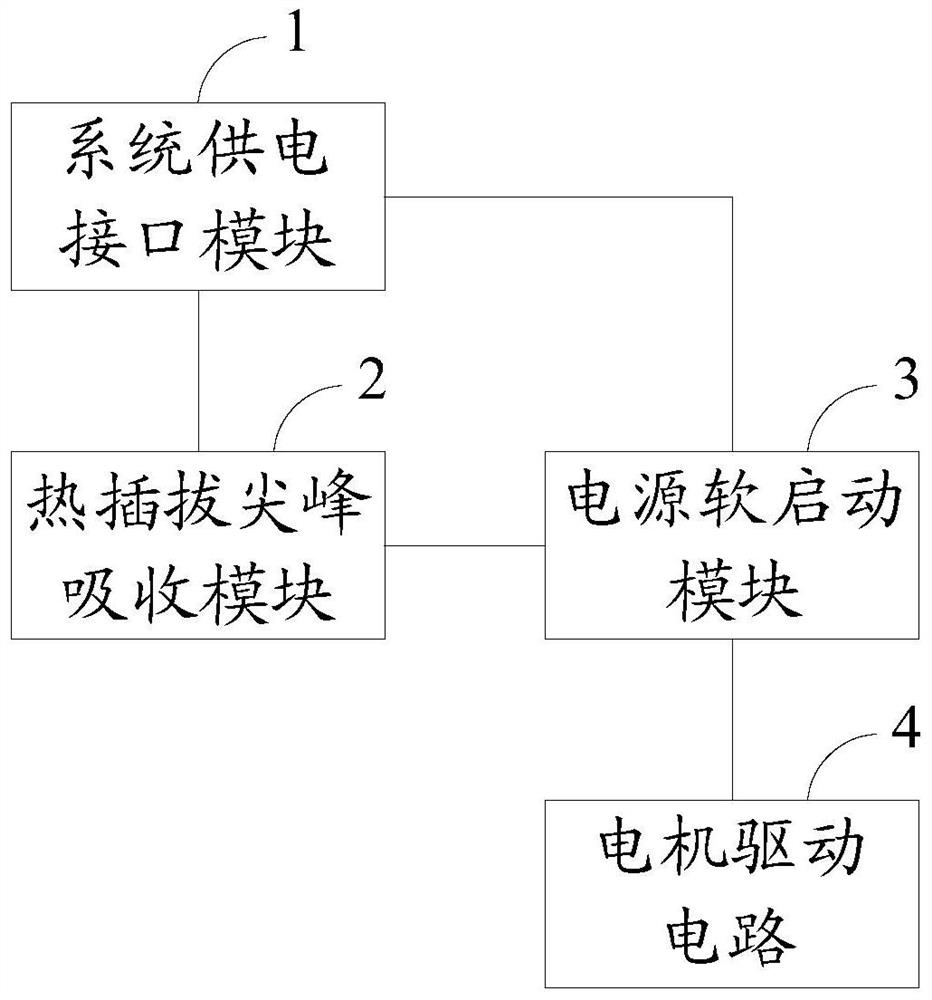

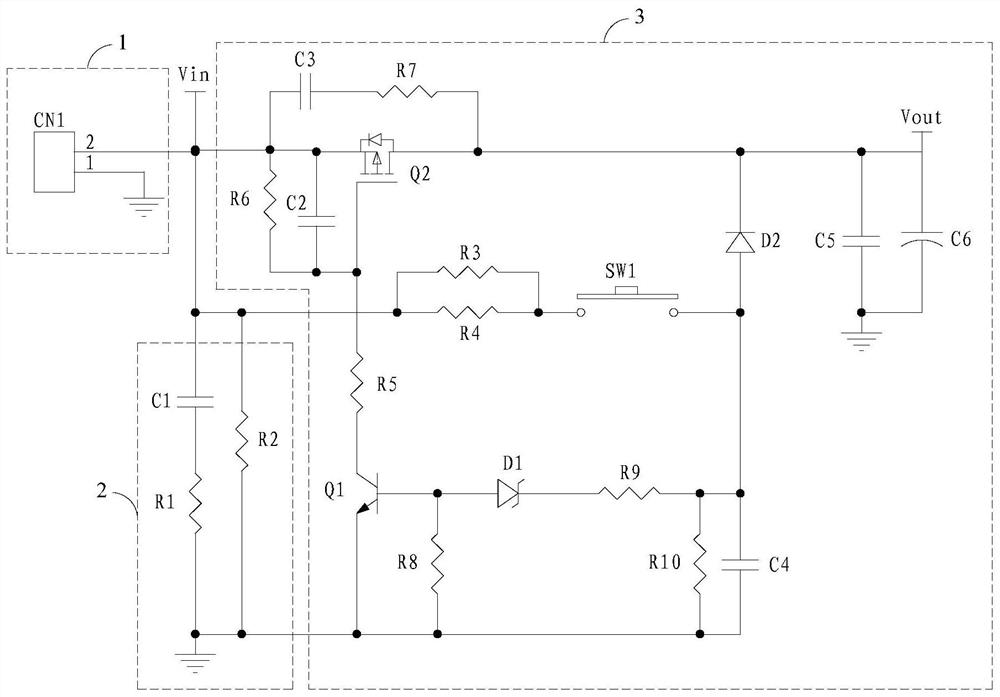

[0032] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is:

[0033] Please refer to figure 1, a power supply soft-start circuit with hot-swap function, comprising a system power supply interface module 1, a hot-swap peak absorption module 2 and a power supply soft-start module 3, the power supply soft-start module 3 is connected with the hot-swap peak absorption module respectively 2 is electrically connected to the system power supply interface module 1, the hot swap peak absorption module 2 is electrically connected to the system power supply interface module 1, and the power soft start module 3 is electrically connected to the peripheral motor drive circuit 4.

[0034] Please refer to figure 2 , the power supply soft start module 3 includes resistor R3 (resistance value is 82Ω), resistor R4 (resistance value is 82Ω), resistor R5 (resistance value is 10kΩ), resistor R9 (resistance value is 1kΩ), resistor R10 (resistance value is 10kΩ), cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com