Automatic umbrella rib riveting device

A technology of a riveting device and a driving device, applied in the field of rivet riveting, can solve the problems of finger injury, long and short nails, poor riveting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

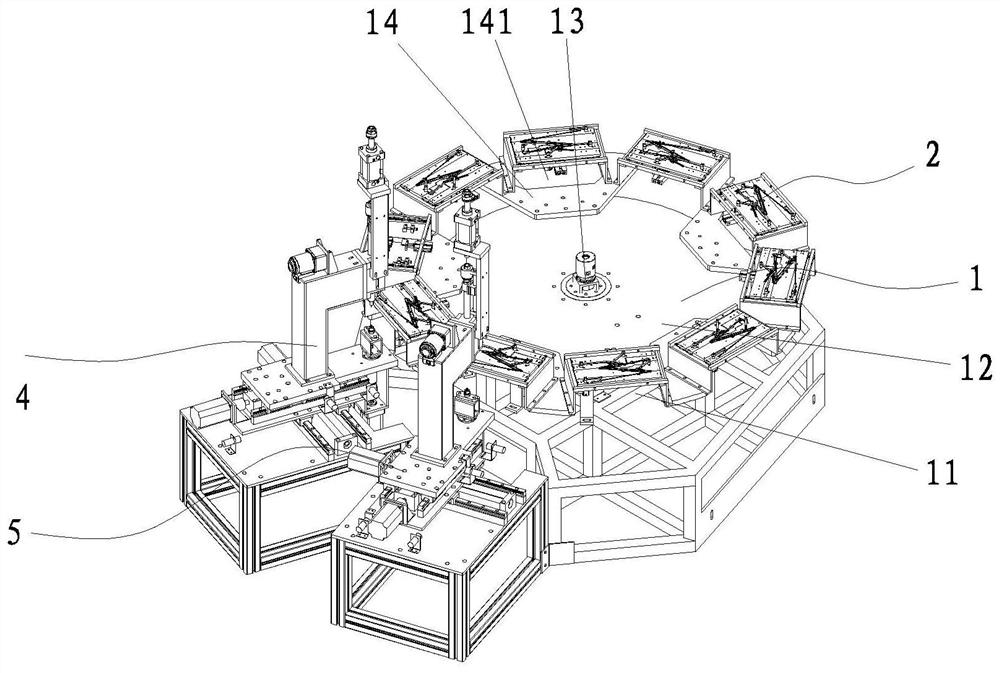

[0054] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

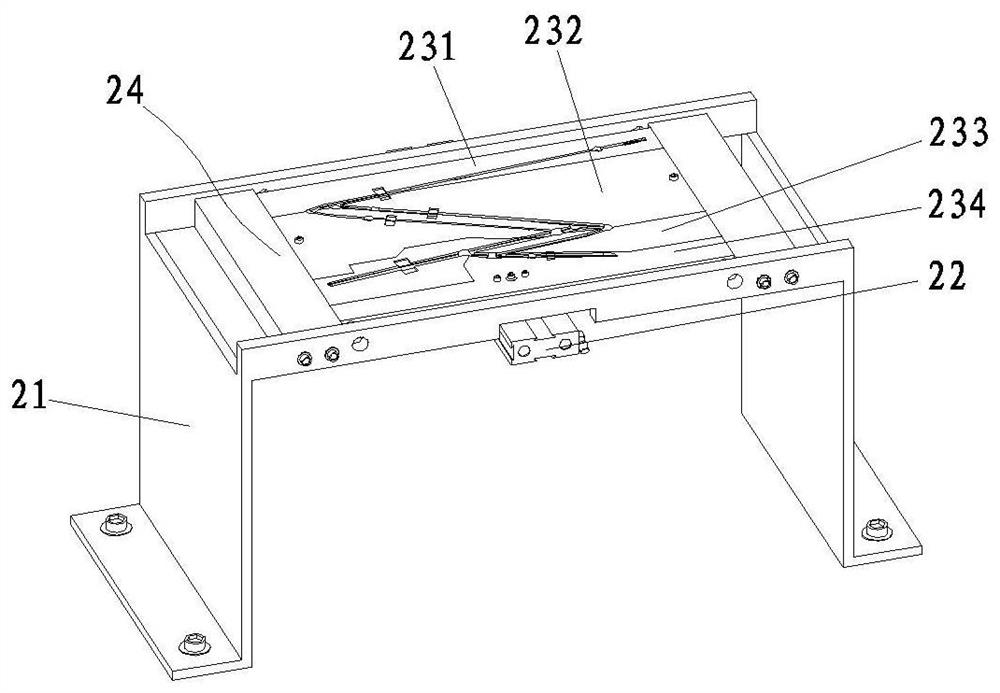

[0055] Such as Figure 1-12 As shown, an automatic riveting device for umbrella ribs, which includes a rotating conveying mechanism 1, on which an umbrella rib tooling 2 for fixing and splicing the umbrella ribs is provided; the outer side of the rotating conveying mechanism 1 is provided with a spike riveting device 4 and the short nail riveting device 5 , the umbrella frame tooling 2 includes several positioning tools, and the positioning tooling includes a first module 231 , a second module 232 , a third module 233 and a fourth module 234 that are sequentially adjacent.

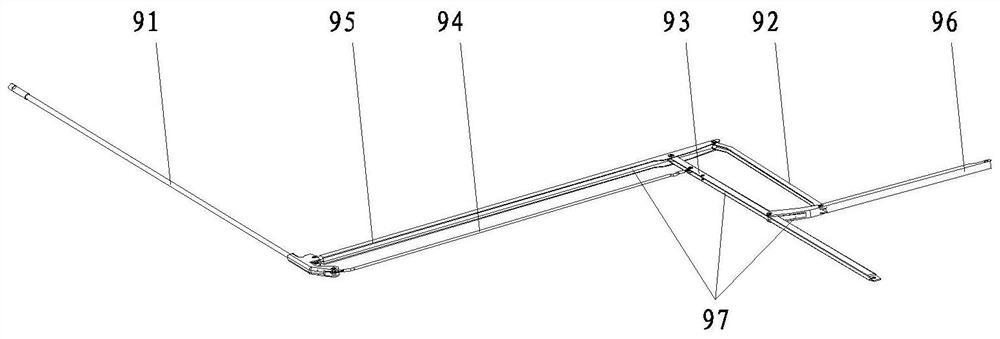

[0056] In the embodiment of the present invention, the structure of the ribs is as figure 2 As shown, the first module 231 is provided with a first positioning groove 271, and the first positioning groove 271 places the round bone 31; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com