Temperature calibration system and method for printer nozzle

A technology for calibrating systems and calibration methods, applied in printing devices, printing, etc., can solve problems such as different resistance values, nozzle temperature detection errors, damage, etc., to achieve the effect of improving printing effects, increasing service life, and eliminating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

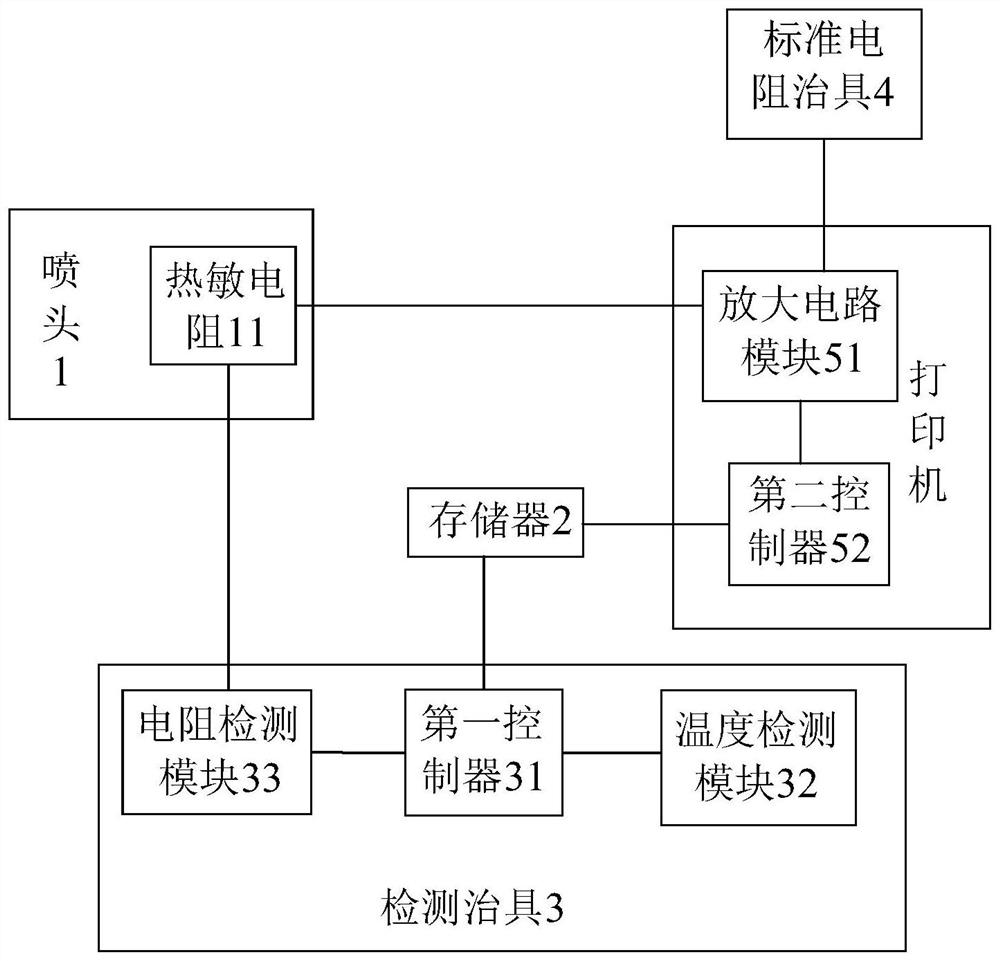

[0018] Such as figure 1 As shown, the printer nozzle temperature calibration system in this embodiment includes a nozzle 1, a memory 2, an amplifier circuit module 51, a second controller 52, a detection fixture 3, and a standard resistance fixture 4 with a known resistance value.

[0019] Wherein the nozzle 1 is provided with a thermistor 11 for detecting the temperature of the nozzle 1. The setting method of the thermistor 11 is set according to specific needs. The thermistor 11 is used to detect the real-time temperature of the nozzle 1 when it is working, thereby preventing the nozzle 1 The temperature is too high and the nozzle 1 is damaged. The resistance value of the thermistor 11 will change with the change of the temperature of the shower head 1 . The resistance-temperature relationship of the thermistor 11 is determined according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com