Thin paper glue scraper

A gluing machine and thin paper technology, which is applied in the field of children's book production, can solve the problems of low manual gluing efficiency and low pass rate, and achieve the effects of high pass rate of finished products, improved work efficiency, and uniform glue quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

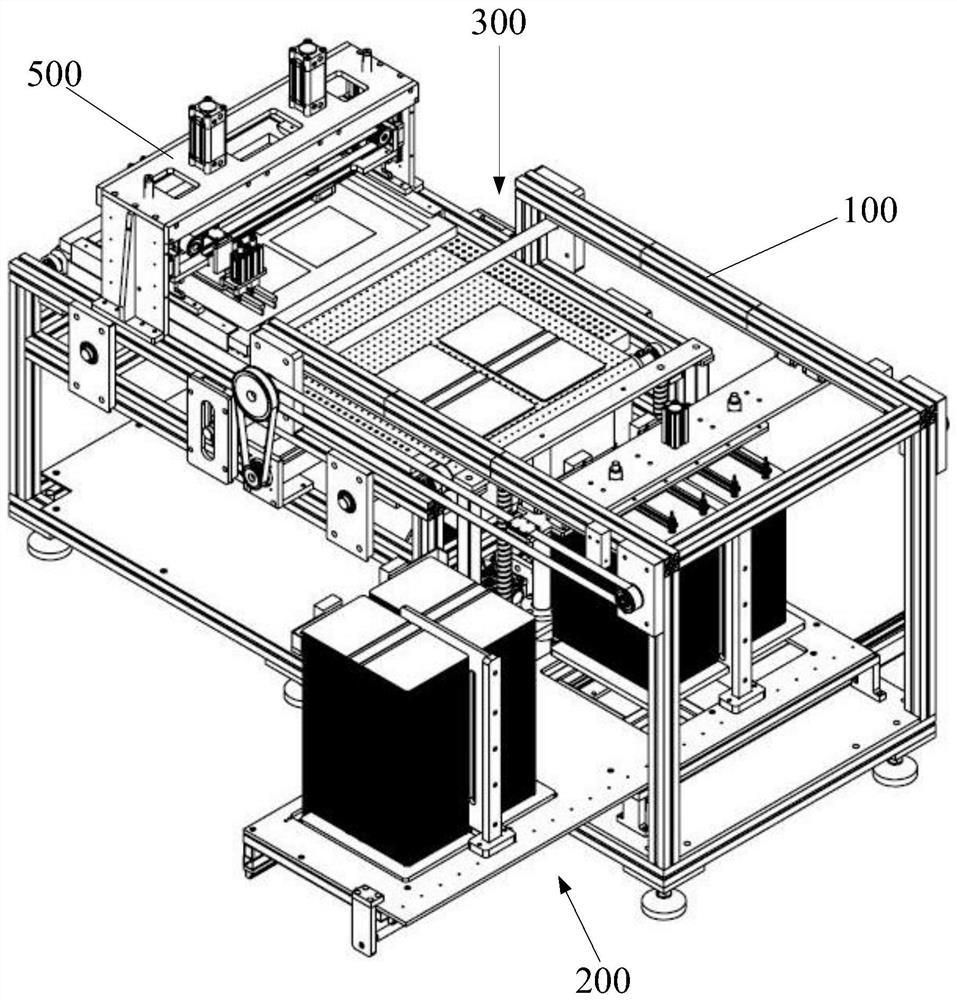

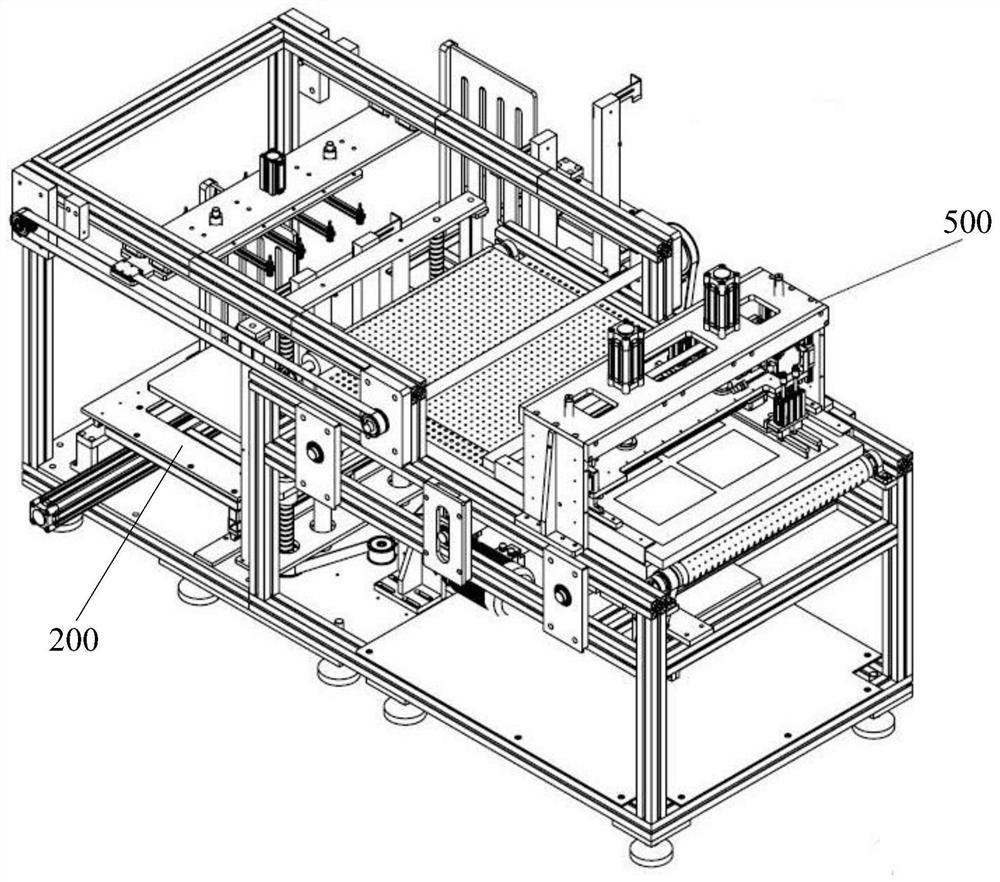

[0038] Such as figure 1 , 2 As shown, the present invention discloses a tissue scraping machine, which includes a frame 100, a bin device 200 installed on the frame, a book case conveying mechanism 300, and a scraper device 500. The bin device 200 is used to store stacked bookcases, and the bookcase conveying mechanism 300 is used to convey the bookcases stored in the bin device 200 to the position of the scraping device 500, and the scraping device 500 is used to align the books The shell is glued.

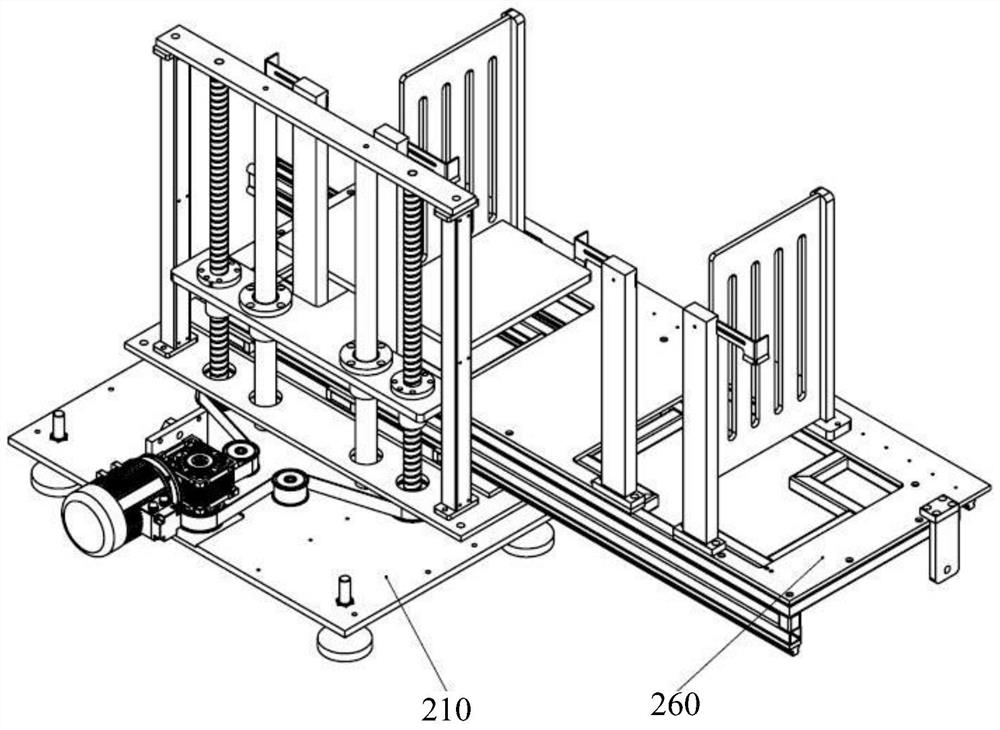

[0039] Such as image 3 As shown, the bin device 200 includes a book case lifting mechanism 210 and a left and right closing mechanism 260. The book case lifting mechanism 210 includes a lifting plate 218, a tooling plate 212, and a lifting plate driving mechanism. The left and right closing mechanism 260 It includes a moving plate 269 and a driving mechanism for the moving plate. The moving plate 269 is provided with a silo, and the silo includes a first silo 2613 and a secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap