Horn mounting structure

A technology for installing structures and horns, applied to electrical components, sensors, etc., can solve problems such as troublesome operation and damage to equipment, and achieve the effects of high practicability, convenient installation and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

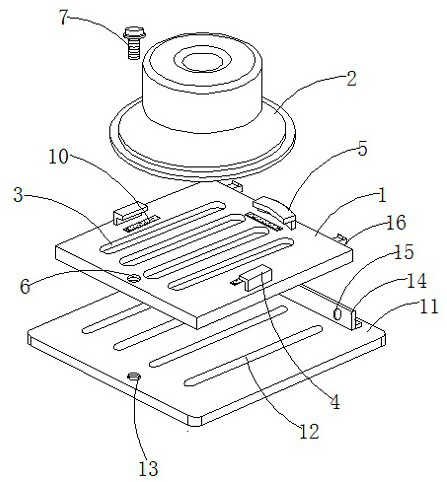

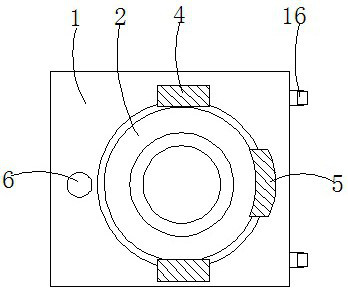

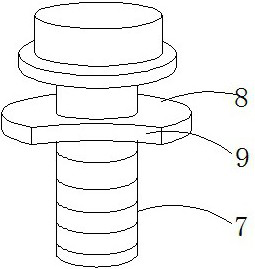

[0022] Such as Figure 1-4 As shown, a horn installation structure includes a horn base 1 and a horn body 2, a plurality of through grooves 3 are provided through the horn base 1, and edge fixing buckles are arranged on the left and right sides of the through groove 3 on the horn base 1 4. There is an arc-shaped fixing buckle 5 on the end of the speaker base 1 close to the through groove 3. The horn body 2 is slidably installed on the inner side of the edge fixing buckle 4 and the arc-shaped fixing buckle 5. The horn base 1 is far away from the arc-shaped fixing buckle 5. The first fixed screw hole 6 is set up and down through one side of the side, and the fixed bolt 7 is movable installed in the first fixed screw hole 6. The fixed bolt 7 is movably covered with a limit rubber pad 8, and the limit rubber pad 8 is located at the edge. There is an arc-shaped groove 9, and the arc-shaped groove 9 cooperates with the edge of the horn body 2. The upper end surface of the horn base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com