Cleaning device for filter cloth of filter press

A technology for cleaning devices and filter presses, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., and can solve the problems of inability to ensure stable performance of filter presses, unreasonable cleaning structure design, and reduced working efficiency of filter presses. and other problems, to achieve the effect of long-term stability of filtration performance, improvement of cleaning effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is introduced below by accompanying drawing.

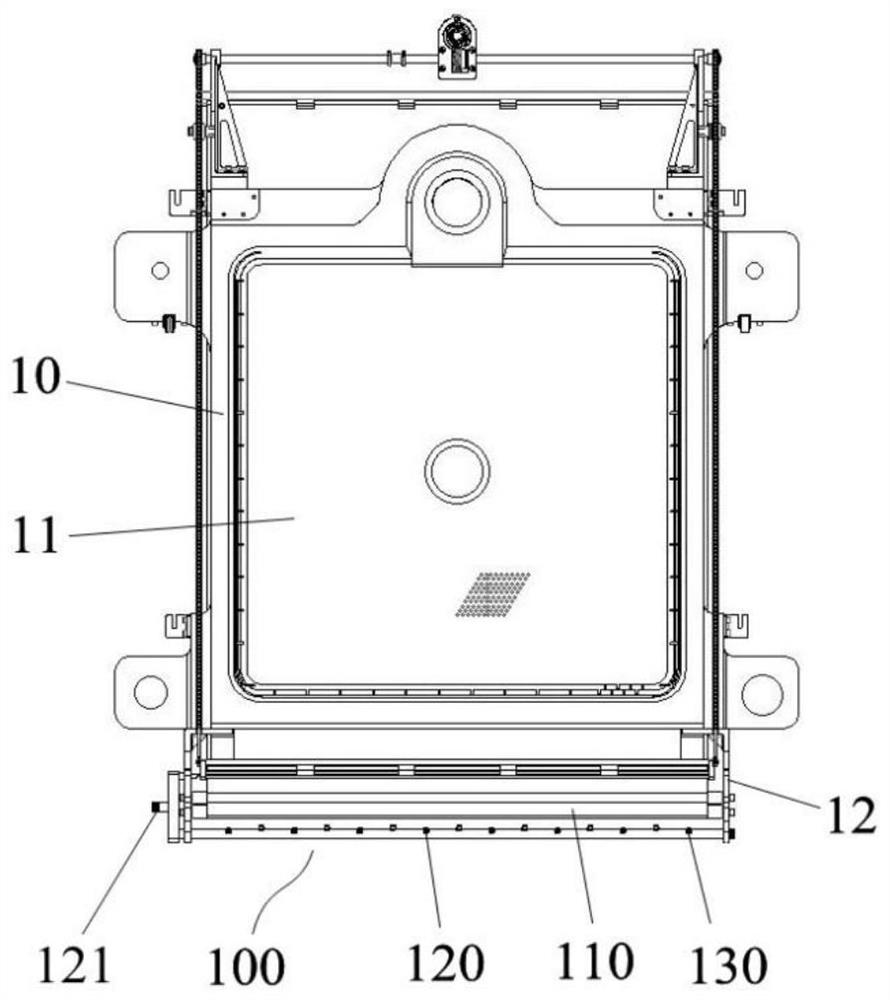

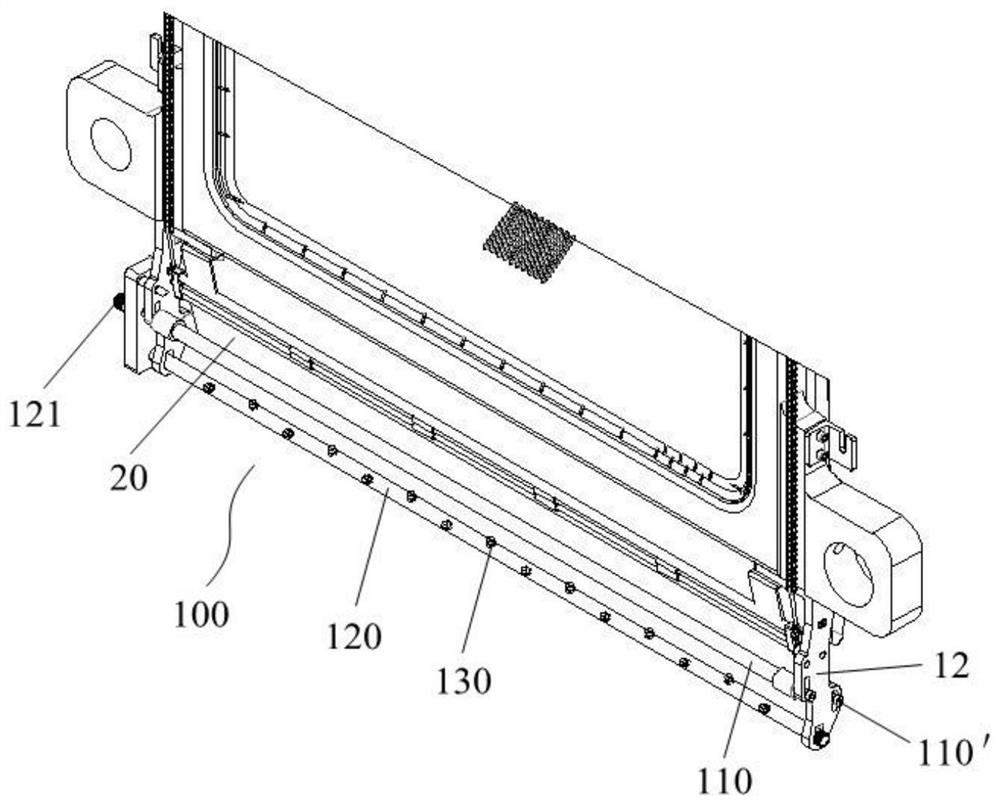

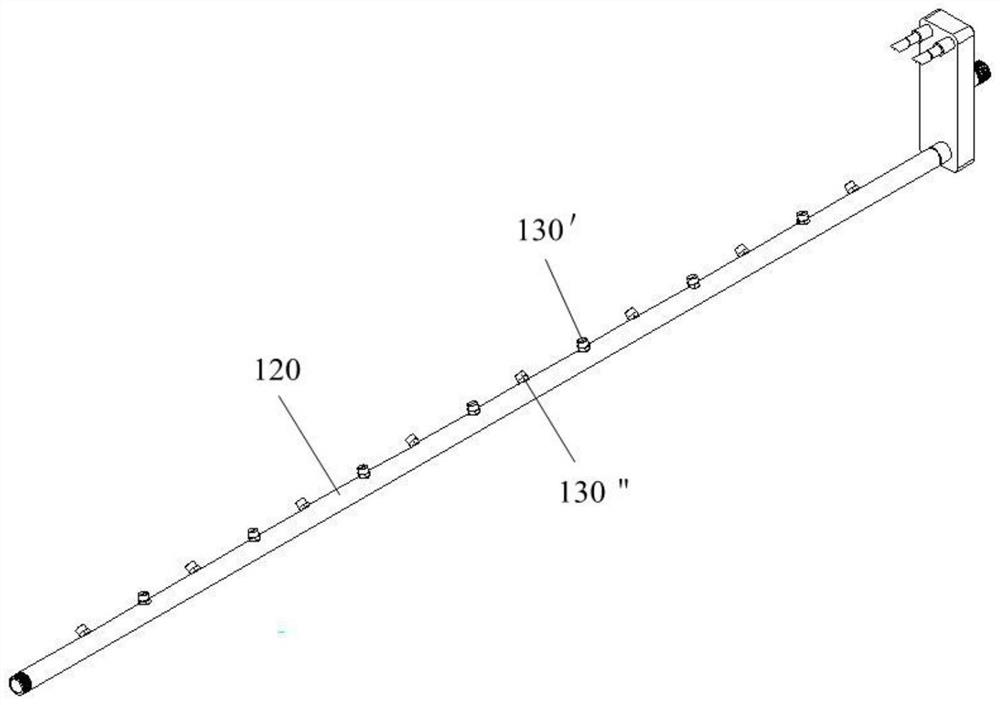

[0025] figure 1 The structure of a cleaning device 100 for a filter cloth of a filter press according to the present invention is shown. The filter press includes a plurality of filter plate units 10 . Such as figure 1 As shown, the filter plate unit 10 includes a filter plate 11 . The cleaning device 100 includes a mounting frame 12 disposed on the lower end of the filter plate 11 . The filter plate unit 10 also includes a filter cloth 20 arranged between adjacent filter plates 11, and two filter cloths 20 are arranged in a cavity formed after two adjacent filter plates 11 are combined. It is enclosed in the frame around the filter plate 11. The material to be filtered enters between the two filter cloths 20 through the feeder between the two filter cloths 20, and under the pressure filtration action of the filter plate 11 of the filter press, the solid material is intercepted by the filter cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com