Automatic classification method and system for multiple types of activated samples

An automatic classification and sample technology, which is applied in the field of automatic classification methods and systems for various types of activated samples, can solve problems such as the inability to realize automatic classification of activated samples, and achieve the effects of fully automatic commutation, noise reduction, and safety assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The automatic sorting system of the embodiment of the present invention may include: an operation table located outside the operation space, and a reversing device, an execution device and a control device located inside the operation space; the operation space is a closed negative pressure or vacuum environment.

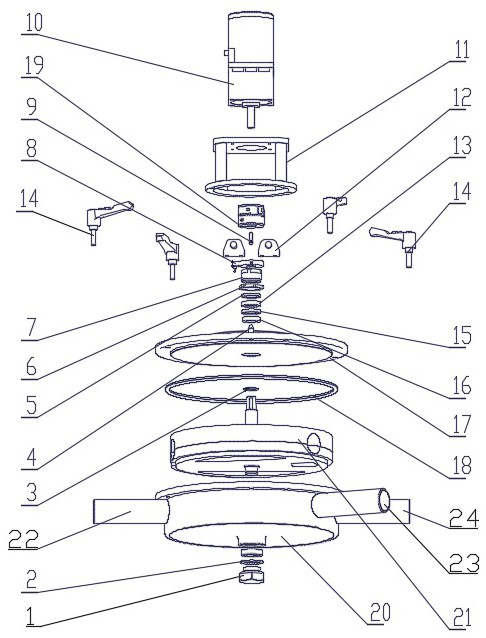

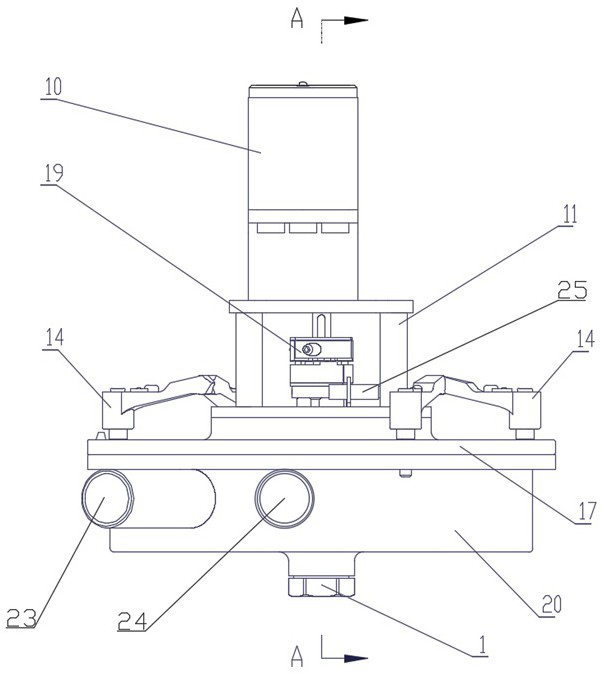

[0062] The reversing device in this embodiment can be a distributing mechanism for classifying cylindrical core materials, and the distributing mechanism in this embodiment can be made of stainless steel or aluminum. Specifically, the reversing device includes: a reversing body provided with a plurality of inlet pipes and outlet pipes (corresponding to the following housing unit), a rotatable assembly embedded with a plurality of channels (corresponding to the following core unit); the execution device receives instructions from the control device to control the rotation of the rotatable components of the reversing device to realize the communication between t...

Embodiment 2

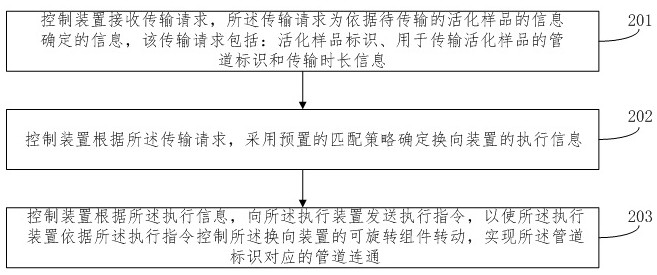

[0076] like figure 2 As shown, the present embodiment provides an automatic classification method for multiple types of activated samples, which may include the following steps:

[0077] 201. The control device receives a transmission request, the transmission request is information determined according to the information of the activation sample to be transmitted, and the transmission request includes: the identification of the activation sample, the identification of the pipeline used to transmit the activation sample, and the transmission duration information.

[0078] For example, the control device receives the transmission request sent by the operation console;

[0079] Or, the control device receives the transmission request sent by any mobile terminal scanning and operating the two-dimensional code.

[0080] 202. The control device determines execution information of the reversing device by using a preset matching strategy according to the transmission request.

[0...

Embodiment 3

[0108] The automatic classification system for multiple types of activated samples in this embodiment includes:

[0109] The operation table located outside the operation space, and the reversing device, execution device and control device located inside the operation space; the operation space is a closed negative pressure or vacuum environment;

[0110] The reversing device includes: a reversing body provided with a plurality of inlet pipes and outlet pipes, and a rotatable assembly embedded with a plurality of channels; the execution device receives instructions from the control device to control the rotation of the rotatable assembly of the reversing device Realize the connection between the inlet and outlet pipes and channels;

[0111] The control device interacts with the execution device through any automatic classification method described in the second embodiment above, so that the specified pipeline in the reversing device is connected.

[0112] In addition, the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com