Lifting and rotating device for automobile manufacturing and implementation method thereof

A technology of automobile manufacturing and rotating device, applied in the direction of lifting device, lifting frame, etc., can solve the problems of poor rotation stability and shorten the service life of hydraulic rod, and achieve the effect of prolonging the service life, improving the rotating stability and improving the stability of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

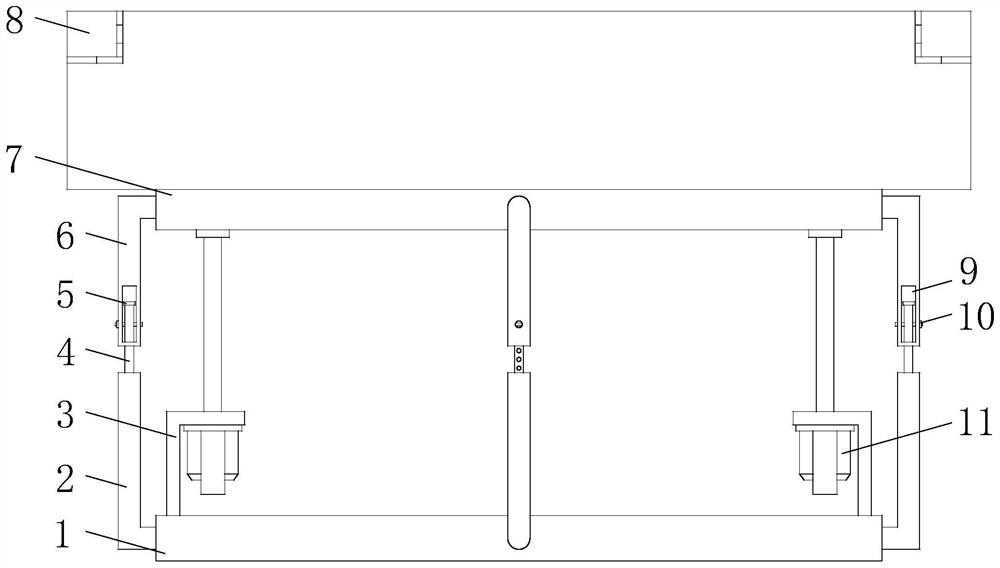

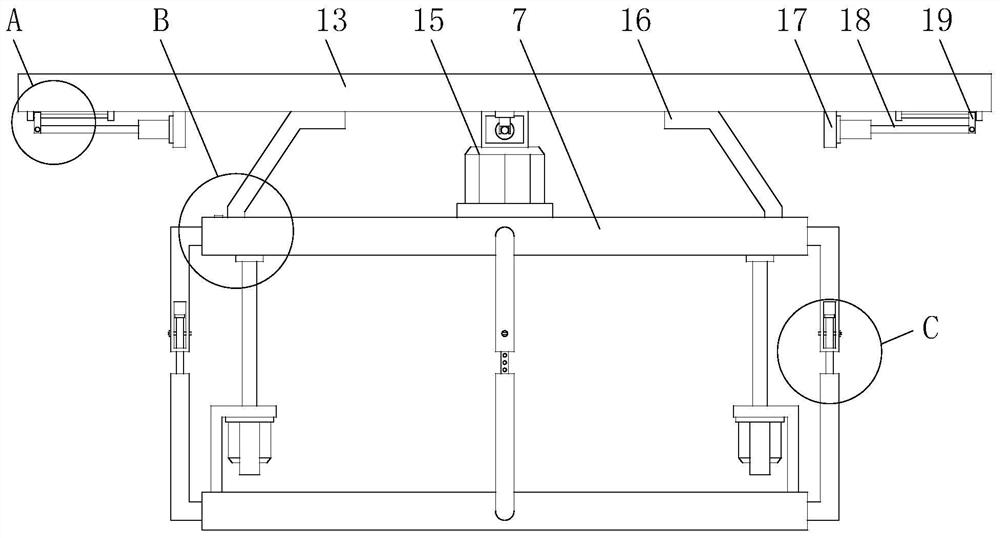

[0032] see Figure 1-8 , the present invention provides the following technical solutions: a lifting and rotating device for automobile manufacturing, including a base 1, first support plates 3 are connected to both sides above the base 1, and first support plates 3 are installed on the two first support plates 3. An electric cylinder 11, a lifting platform 7 is arranged above the base 1, the output shaft ends of the two first electric cylinders 11 are connected with the lifting platform 7, and several lower support rods 2 are evenly distributed on the outer edge of the base 1. The tops of the lower support rods 2 are all connected with extension rods 4, the outer edge of the lifting platform 7 and the positions corresponding to several lower support rods 2 are connected with upper support rods 6, and the bottom ends of several upper support rods 6 are all opened. There is a moving groove 9, and several extension rods 4 pass through the bottom ends of the corresponding upper s...

Embodiment 2

[0041] The difference of this embodiment compared with embodiment 1 is:

[0042] Specifically, both sides of the bottom end of the rotating table 8 are connected with auxiliary support frames 16, and the bottom ends of the two auxiliary support frames 16 are connected with rotating balls 22. Annular rotating groove 23,

[0043] By adopting the above technical solution, during the rotation of the rotating table 8 , the rotating ball 22 below the auxiliary support frame 16 rotates synchronously in the annular rotating groove 23 on the lifting table 7 , which can improve the rotation stability of the rotating table 8 .

[0044] Specifically, an oil injection channel is provided on one side of the lifting platform 7 and located at the annular rotating groove 23, the oil injecting channel and the annular rotating groove 23 are provided in a connected structure, and the top of the oil injecting channel is provided with a cork.

[0045] By adopting the above technical scheme, the oi...

Embodiment 3

[0048] The difference of this implementation compared with embodiment 1 and embodiment 2 is:

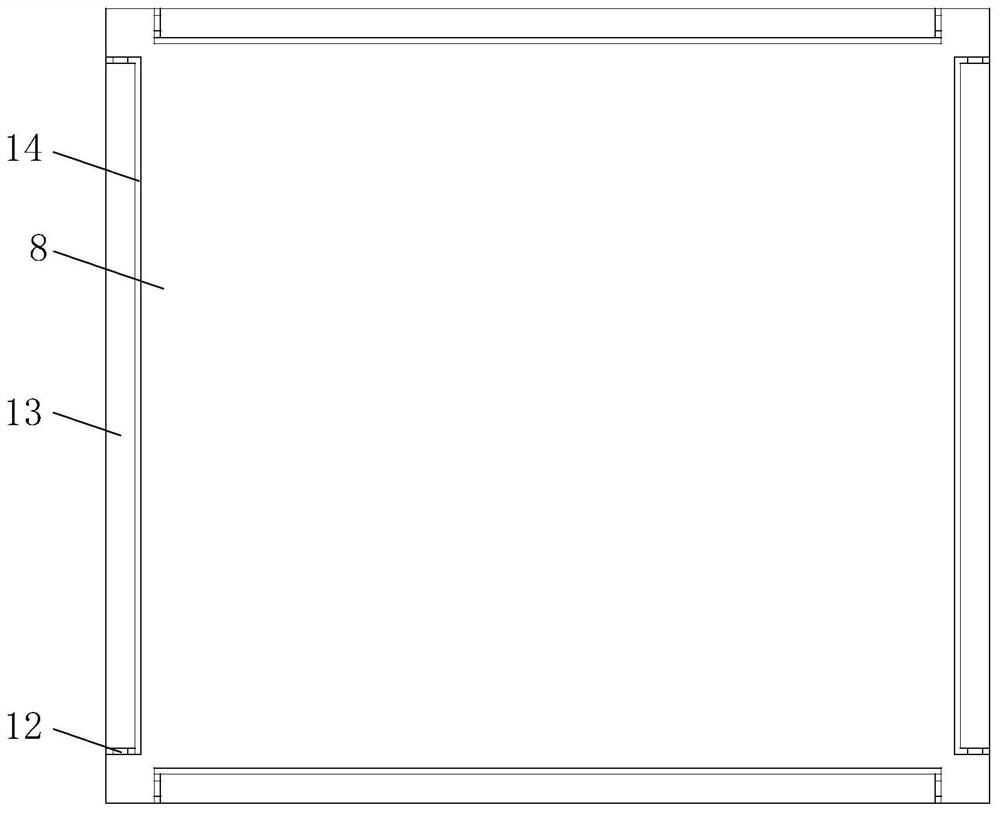

[0049] Specifically, the four sides of the rotary platform 8 are provided with installation grooves 14, and the insides of the four installation grooves 14 are all provided with extension platforms 13, and the four extension platforms 13 are connected to the corresponding installation grooves 14 through rotation shafts 12. The bottom of each extension platform 13 is connected with two fixed plates 21, and the polished rod 20 is connected between the two fixed plates 21. The polished rod 20 is slidably connected with a moving block 19, and the bottom four side walls of the rotary table 8 are connected with a second The supporting plate 17 and the four second supporting plates 17 are equipped with second electric cylinders 18 on one side close to the moving block 19 , and the output shafts of the four second electric cylinders 18 are hinged to the corresponding side moving block 19 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com