Putty powder painting device for construction site

A construction site and putty powder technology, which is applied in construction, building construction, etc., can solve the problems of waste of putty powder that is difficult to clean on polluted ground, the scraper has no receiving device, and powder dripping, etc., so as to avoid internal agglomeration and precipitation , save energy, expand the shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

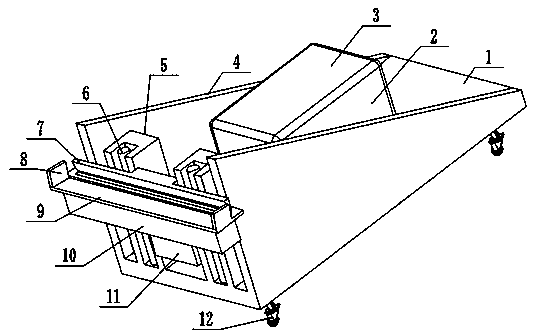

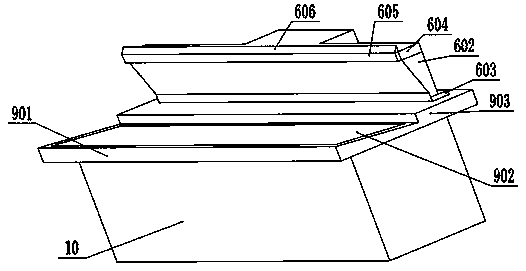

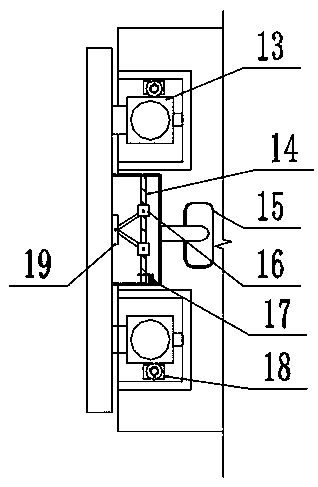

[0031] refer to Figure 1-4 , a construction site with putty powder painting device, including a base 1, the top of the base 1 is provided with a material storage box 2 and a pumping machine 15, and the input end of the pumping machine 15 is connected to the material storage box 2 through a conduit The top of the material storage box 2 is hinged with a top cover 3, and one side of the top of the base 1 is welded with two fixing seats 5, and a lifting mechanism is arranged in the fixing seats 5, and one side of the fixing seats 5 A storage receiving mechanism is provided, and the output end of the pumping machine 15 is connected with the storage receiving mechanism through a conduit. One side of the storage receiving mechanism is provided with a painting mechanism, and both sides of the top outer wall of the base 1 are welded. Side frame 4 is arranged, and side frame 4 is a triangular structure, and the four corners of the bottom outer wall of base 1 are all fixed with universa...

Embodiment 2

[0041] refer to figure 1 and Figure 5 , a construction site with putty powder painting device, compared with embodiment 1, in order to avoid the phenomenon of uneven mixing of putty powder in the material storage box 2, the present invention also includes a vibrating plate 24 fixed on the top of the base 1, And the pumping machine 15 is fixedly connected to the side wall of the vibrating plate 24, and the side wall of the vibrating plate 24 is welded with several springs 23 fixed on the inner wall of the material storage box 2, and the bottom end of the spring 23 is welded with several metal sheets 22, Preferably, the vibrating plate 24 is an elastic metal plate structure, which can transmit the vibration of the pumping machine 15, and the fluctuation of the metal sheet 22 is driven by the fluctuation of the spring 23, thereby expanding the shaking of the putty powder in the material storage box 2 and avoiding the vibration of the putty powder inside the storage box 2. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com