Electric bogie with material receiving sealing device

An electric trolley and sealing device technology, applied in the directions of loading/unloading, transportation and packaging, conveyor objects, etc., can solve problems such as affecting the health of operators, generating dust, and spreading dust, and achieves improved adaptability, avoidance of dust, and better performance. The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

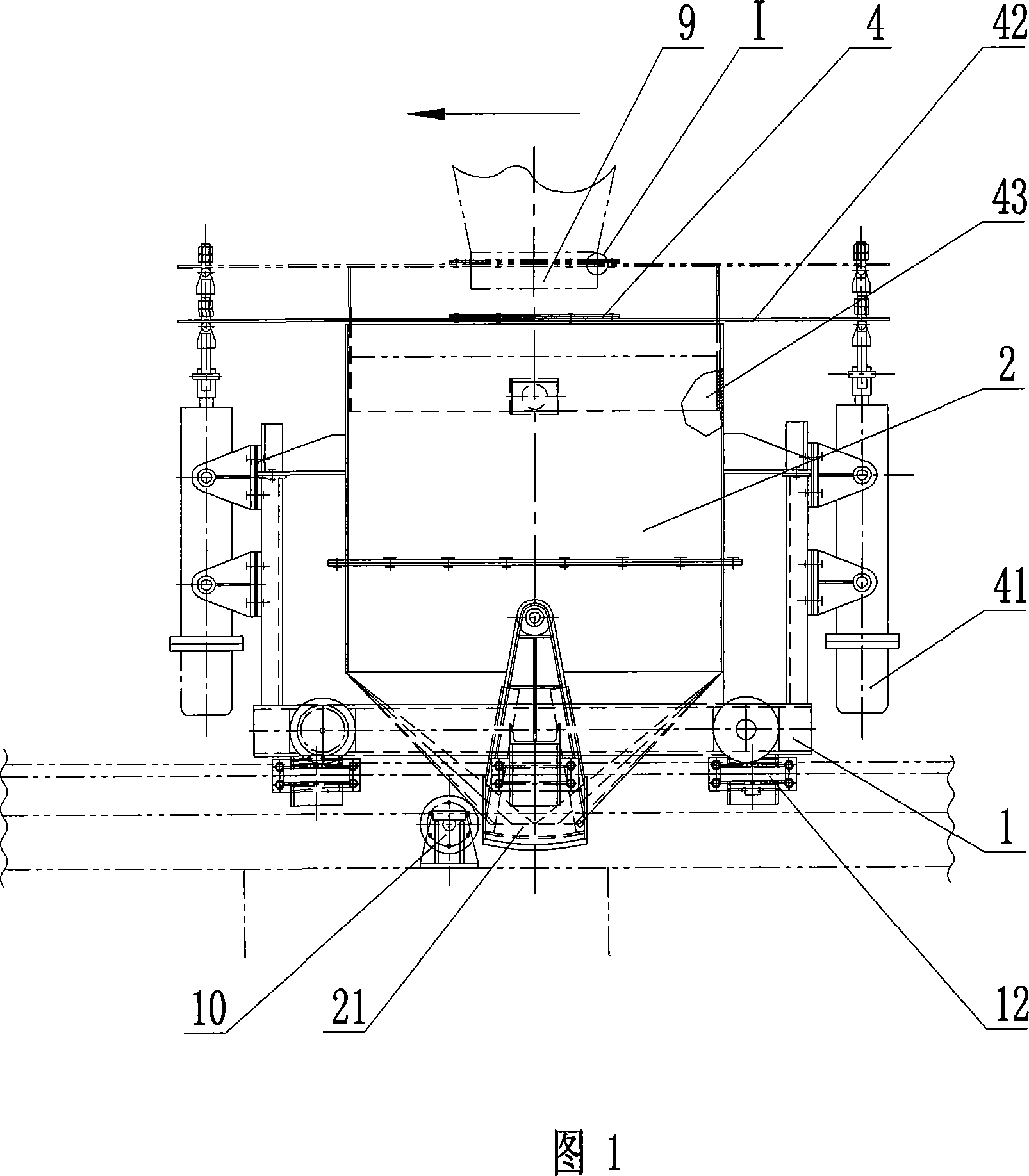

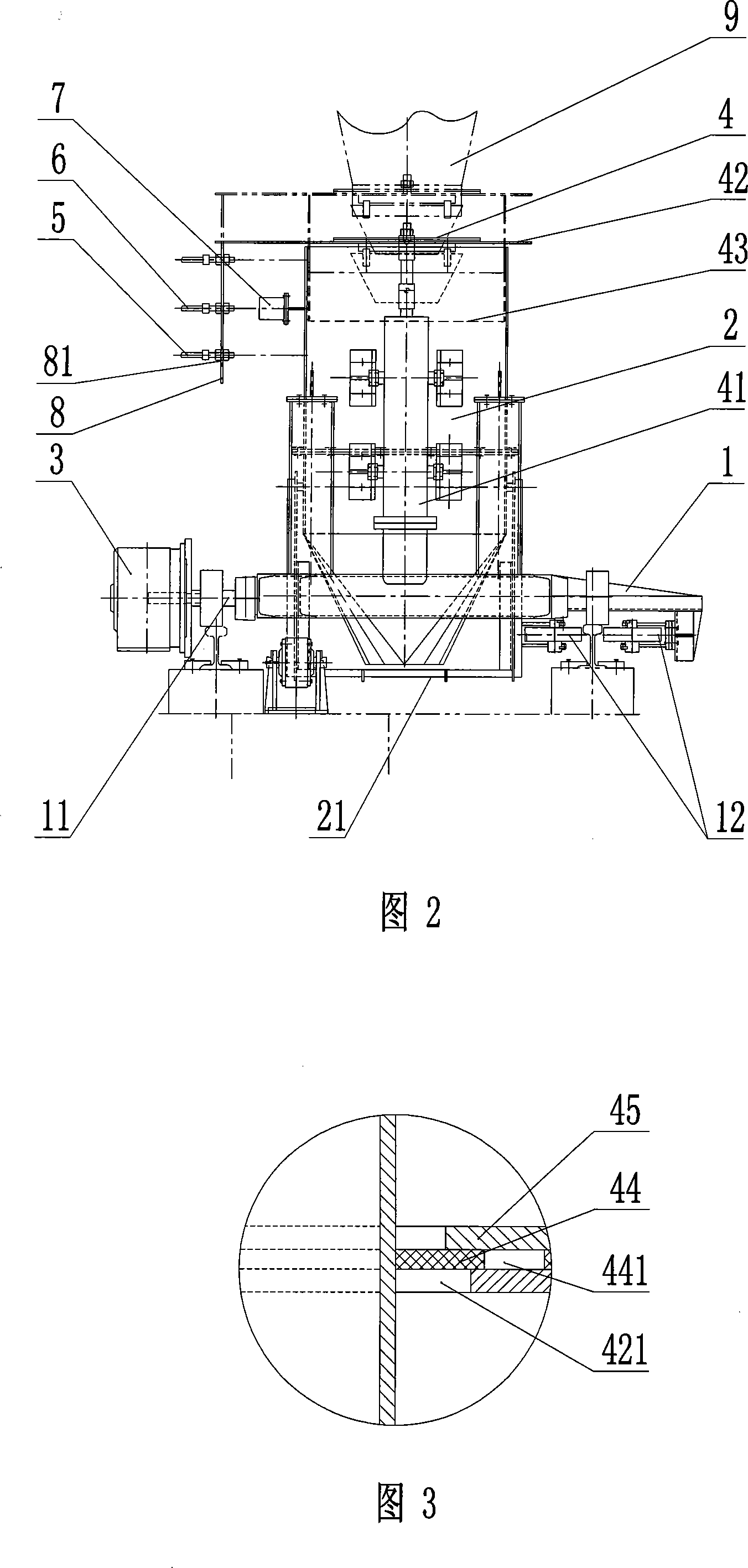

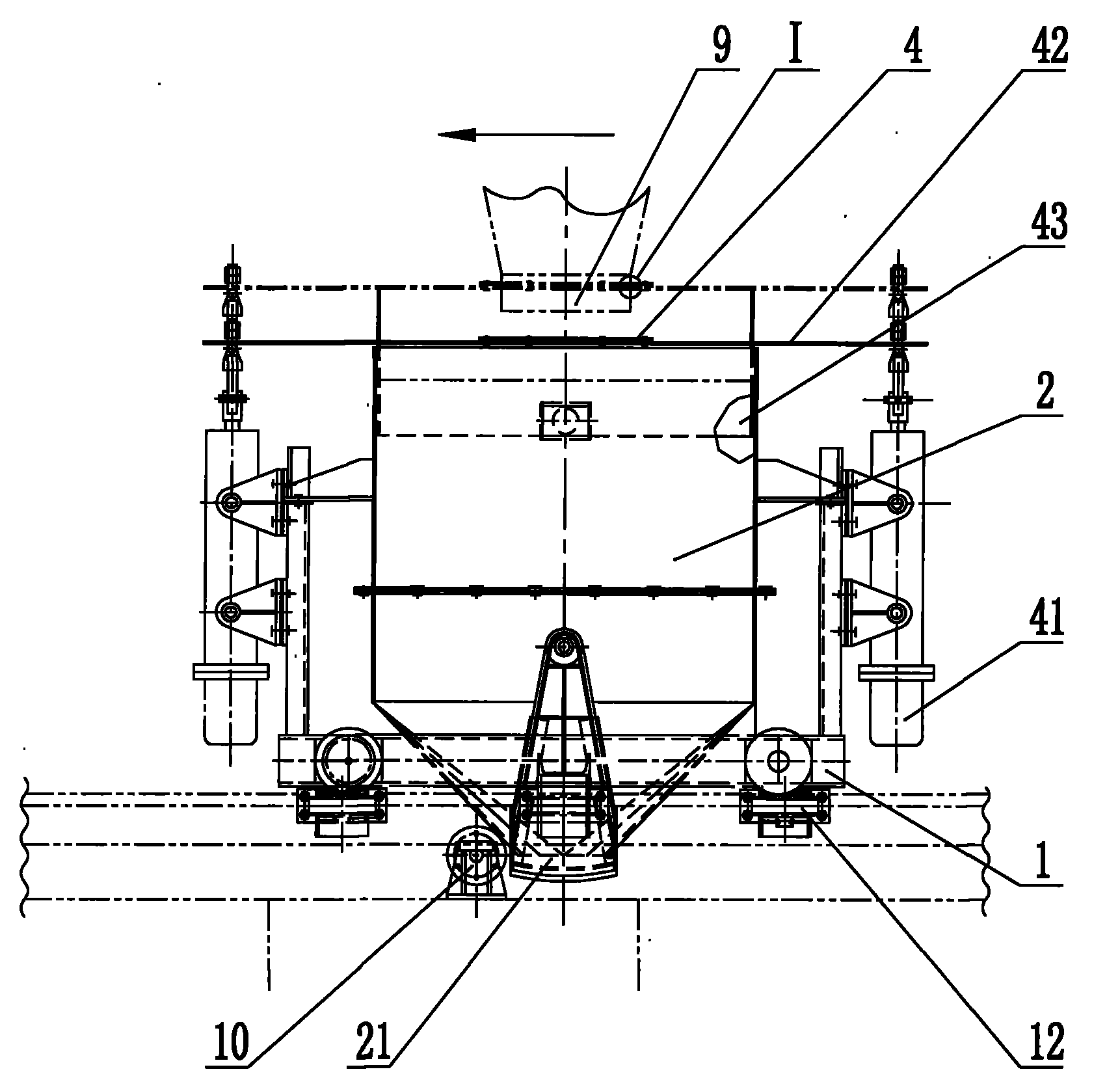

[0029] Such as figure 1 , figure 2 with image 3 As shown, the electric trolley with material receiving sealing device of the present invention includes a vehicle frame 1 and a hopper 2 installed on the vehicle frame 1, and a traveling shaft 11 with wheels is respectively installed at the front and rear ends of the vehicle frame 1. The shaft end of the root traveling shaft 11 is equipped with a motor 3 that drives the trolley to advance, and one side of the vehicle frame 1 is equipped with three guide wheels 12 that cooperate with the track of the electric trolley, and two of the guide wheels 12 located on the outside of the track are respectively arranged At the front and rear ends of the vehicle frame 1, a guide wheel 12 located on the inner side of the track is arranged in the middle of the vehicle frame 1. A fan-shaped discharge door 21 is installed at the lower end of the hopper 2, and a fan-shaped discharge door 21 is arranged beside the track. Coordinated unloading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com