Caisson hanging formwork structure

A technology of caisson and mold hanging, which is applied in the fields of formwork/formwork components, building structures, and on-site preparation of building components. Reasonable design and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

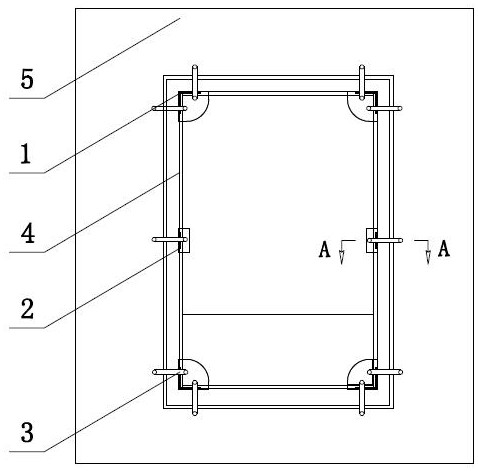

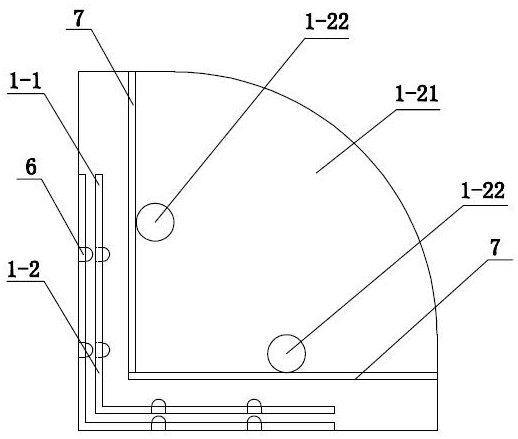

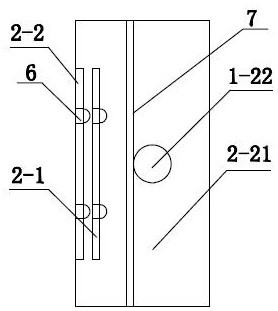

[0017] With reference to the accompanying drawings, a caisson hanging formwork structure includes a formwork part and a formwork hanging part.

[0018] The formwork hanging part includes: four formwork fixing corner brackets 1 , a set of formwork side fixing supports 2 and a set of formwork hanging reinforcement hoops 3 .

[0019] The template fixed angle bracket 1 includes: an upper template fixed angle bracket 1-1 and a lower template fixed angle bracket 1-2, and the upper template fixed angle bracket 1-1 and the lower template fixed angle bracket 1-2 are overlapped and fixed to form a template The design height of the fixed angle bracket 1, the bottom of the lower formwork fixed angle bracket 1-2 is fixed with a fixed angle bracket bottom plate 1-21, and the fixed angle bracket bottom plate 1-21 is fixed with a steel bar hoop connection screw 1-22, and the connection screw 1-21 22 is the thickness of the template 4 at a distance from the fixed angle bracket 1-2 of the templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com