Upper locking type elastic conical locknut

A technology of elastic cones and anti-loosening nuts, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems such as the large impact on the service life of bolts, and achieve the effect of preventing loosening and retreating, reducing adverse effects, and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

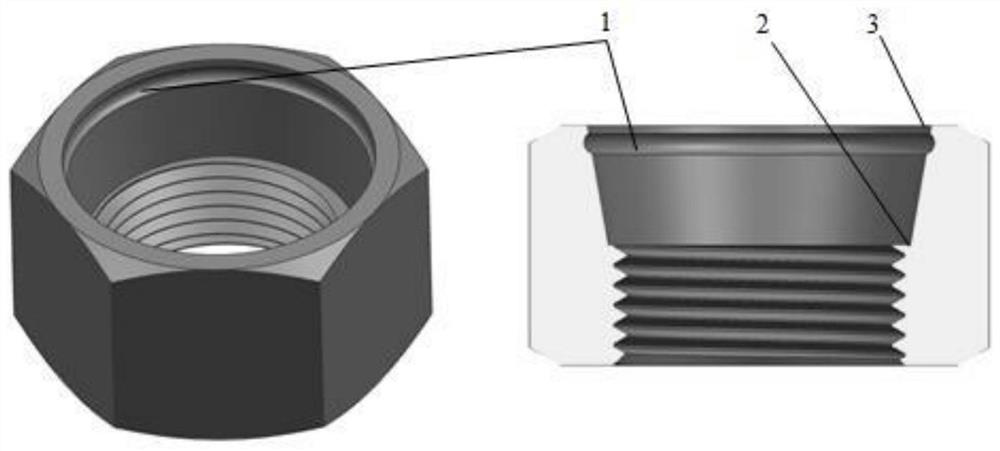

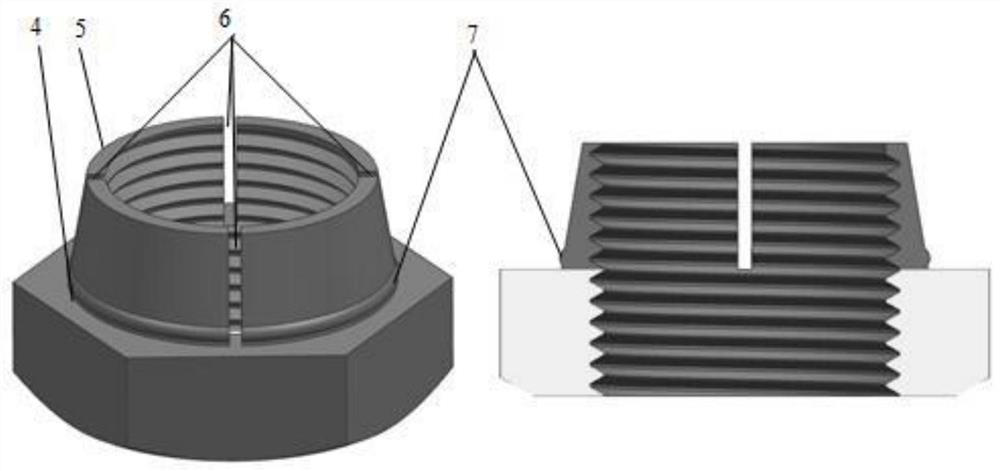

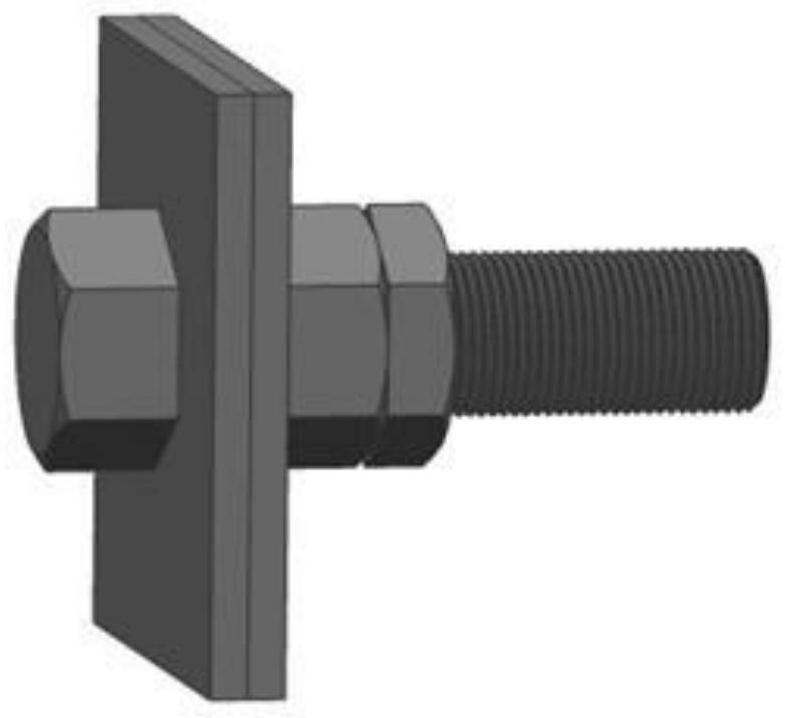

[0025] like figure 1 , figure 2 and image 3 As shown, first screw the thick nut with the inner conical hole on the bolt, the direction of the inner conical hole is facing outward, use a wrench to tighten it to the force value required for installation, and then screw the thin nut with the outer conical boss onto the bolt Above, the outer conical boss is facing the inner conical hole. Use a wrench to screw the outer conical boss of the thin nut into the inner conical hole of the thick nut. Since the outer conical boss is provided with a deformation groove, it will , each part of the outer conical boss deforms at the same time until the arc-shaped section protrusion screwed on the outer conical boss snaps into the arc-shaped section groove on the wall of the inner conical hole, at this time the thick nut and the thin nut are connected as o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com