A self-regulating temperature-compensated clamp

A technology of temperature compensation and self-regulation, which is applied in the direction of hose connection devices, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve problems such as inability to achieve self-regulation, leakage, and increased hardness, and achieve the effect of shortening product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

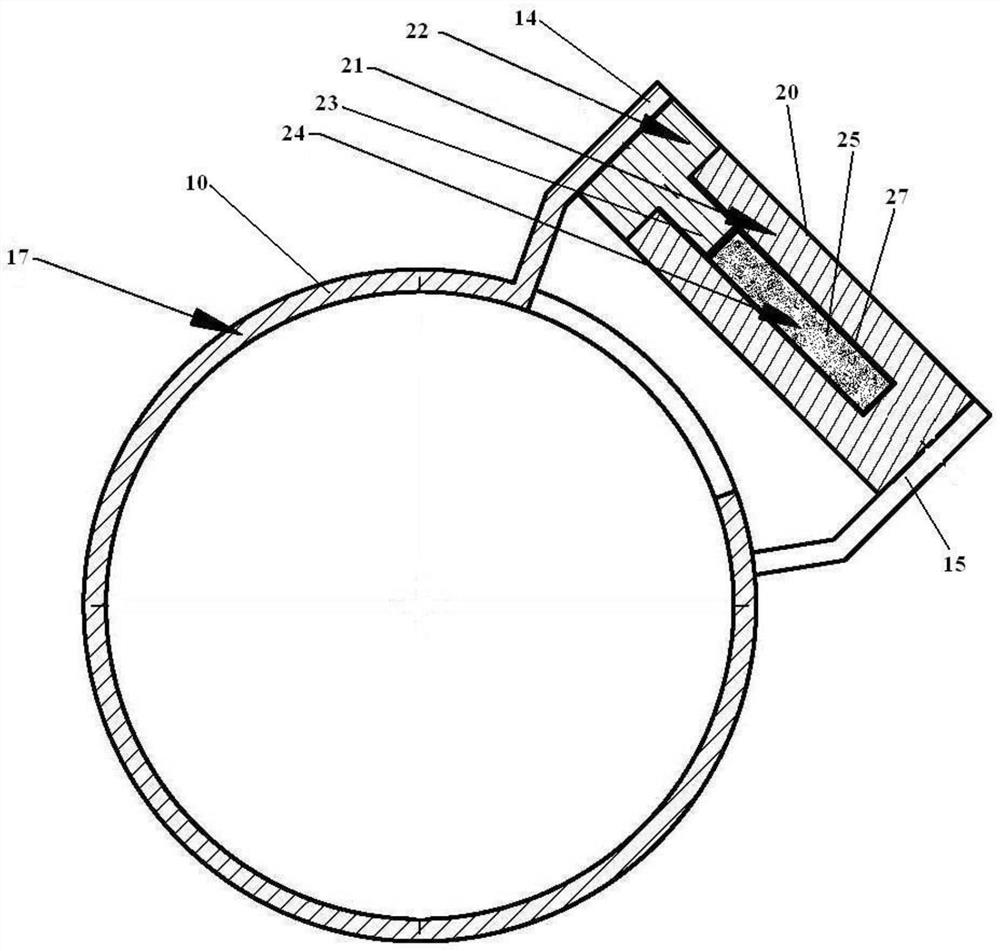

[0026] combine figure 1 As shown, a self-adjusting temperature compensation clamp includes an integrally formed elastic clamp band 17 and an expansion tube 20, the elastic clamp band 17 has a first connection end 14 and a second connection end 15, and the expansion tube 20 includes an outer One end of the outer cylinder 21 is closed and the other end is open. The outer cylinder 21 has a first cavity 23 and a second cavity 24 extending from the open end to the closed end along the axial direction of the outer cylinder 21. The first cavity 23 communicates with the second cavity 24, and the extending end of the lining core 22 extends into the first cavity 23 through the opening end of the outer cylinder 21, and the lining core 22 is slidingly connected with the inner wall of the outer cylinder 21. The protruding end of 22 abuts against the first connecting end 14 of the elastic clamp band 17, and the second cavity 23 is completely filled with an expansion medium 25. In this embod...

Embodiment 2

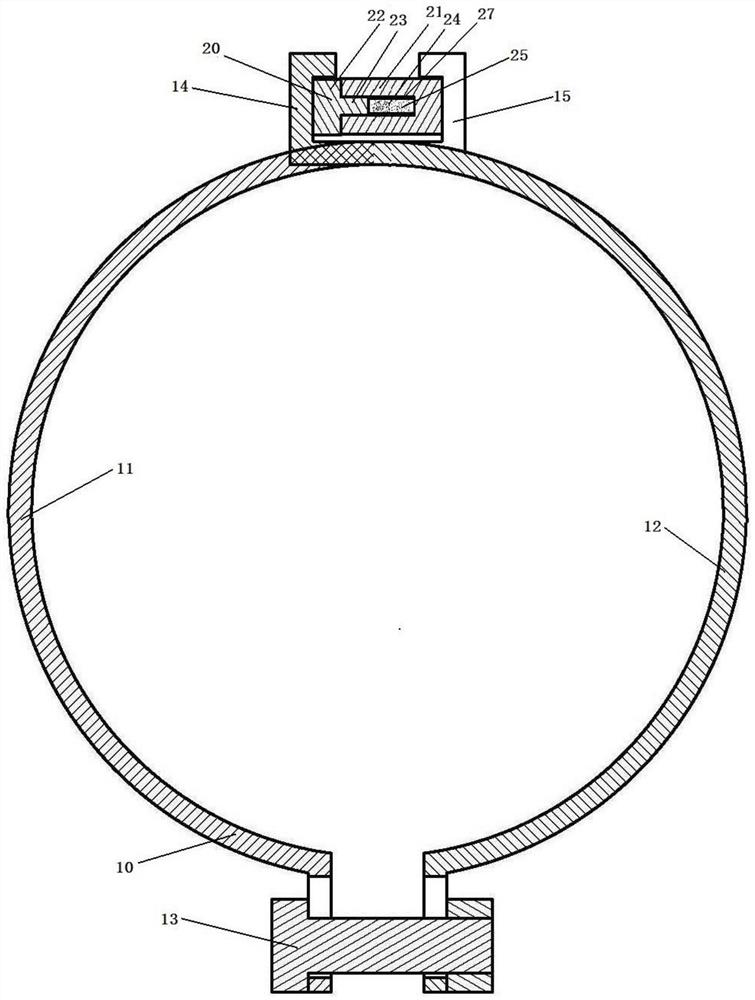

[0035] combine figure 2 As shown, a self-adjusting temperature-compensated clamp includes a clamp body 10 and an expansion tube 20. The clamp body 10 includes two semicircular clamps and a connecting piece 13. The two semicircular clamps are respectively left clamps 11 and the right clamp 12, the lower end of the left clamp 11 and the lower end of the right clamp 12 are connected by a connector 13, the connector 13 is a bolt in this embodiment, the upper end of the left clamp 11 is the second connection end 15, the right The upper end of the hoop is the first connecting end 14, the upper end of the left hoop 11 and the upper end of the right hoop 12 are arranged crosswise, and a reaction force structure is set, that is, when the two ends are close to each other, the inner diameter of the hoop body 10 increases, and the two ends are far away from each other. At this time, the inner diameter of the clamp body 10 decreases.

[0036] The expansion tube 20 is arranged between the...

Embodiment 3

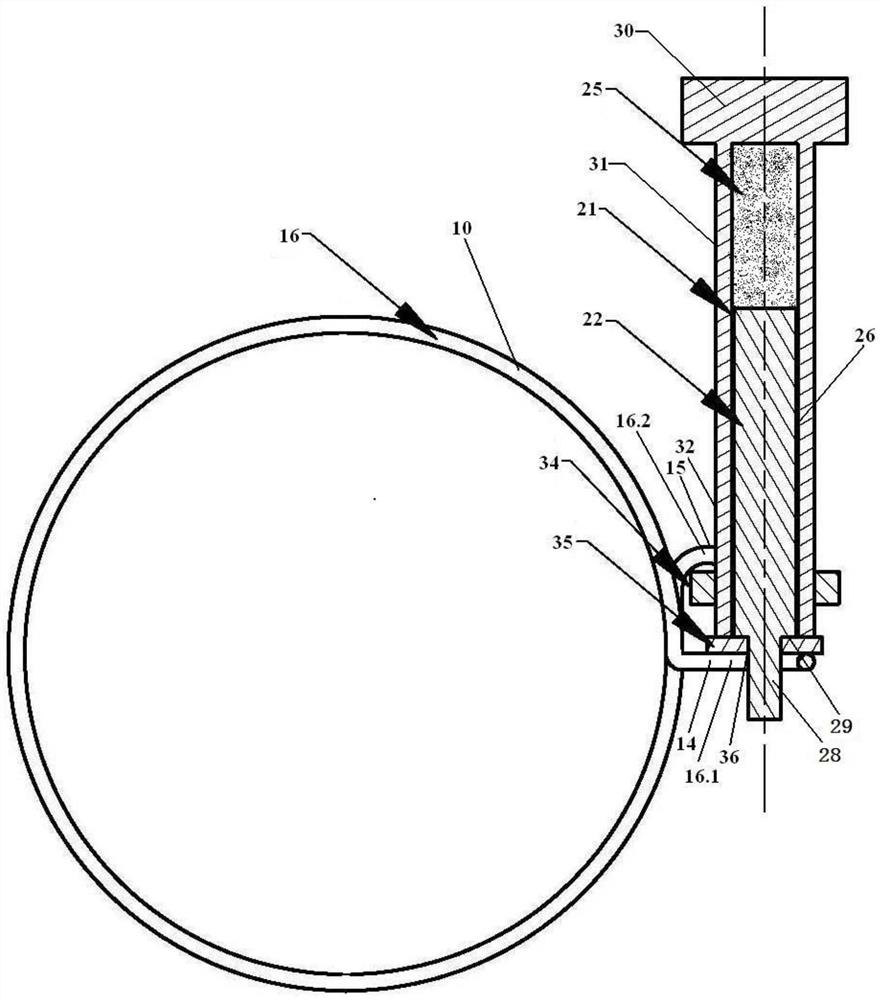

[0039] combine image 3 As shown, a self-adjusting temperature compensation clamp includes an integrally formed double steel wire snap ring 16, an expansion tube 20 and a locking member 30. The double steel wire snap ring 16 is a steel wire bent from the middle to form a double row of steel wires , one end of which includes two hook-shaped steel wire heads 16.2, and the other end includes an arc-shaped collar 16.1. The expansion tube 20 includes an outer cylinder 21 and a lining core 22. One end of the outer cylinder 21 is closed and the other end is open. The first cavity 23 and the second cavity 24 extending from the open end to the closed end in the axial direction of the outer cylinder, the first cavity 23 and the second cavity 24 communicate with each other, and the extending end of the lining core 22 passes through the outer cylinder 21 The opening end extends into the first cavity 23, the lining core 22 is slidingly connected with the inner wall of the outer cylinder 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com