Testing system and testing method for static friction torque of clutch

A technology of static friction and testing system, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc. It can solve the problems of potential safety hazards, easy to pollute the environment, time-consuming and labor-intensive connections, etc., and achieve the effect of convenient and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

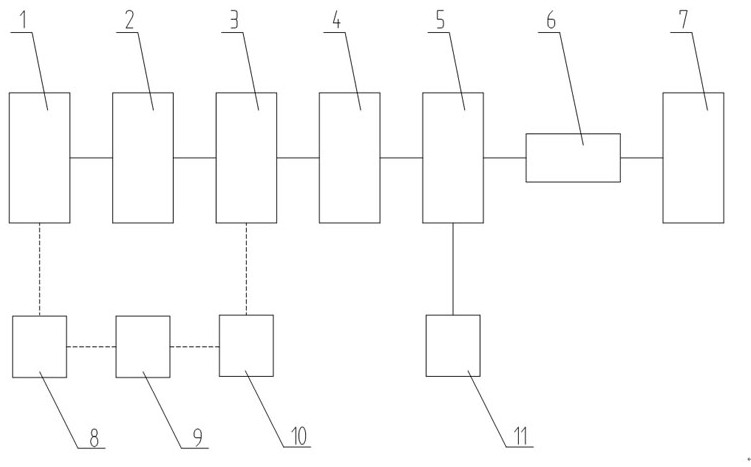

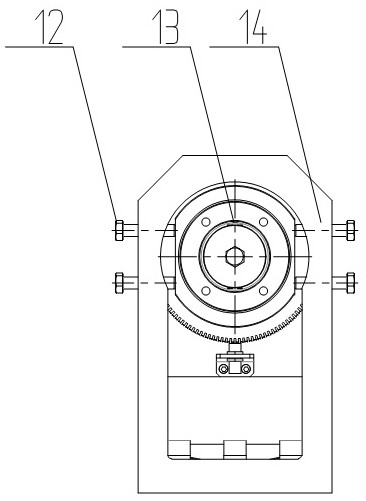

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as Figure 1~2 As shown, the structure of a test system for clutch static friction torque includes: drive motor 1, shift reducer 2, torque sensor 3, clutch assembly 4, clutch control mechanism 5, transmission shaft 6, fixing device 7, drive frequency conversion Device 8, upper computer 9, data acquisition system 10, hydraulic station 11: wherein: the upper computer 9 is connected to the data acquisition system 10 and the drive frequency converter 8 by cables, the data acquisition system 10 is connected to the torque sensor 3 by cables, and the drive The frequency converter 8 is connected to the driving motor 1 through a cable, and the host computer 9 sends commands to the driving frequency converter 8 to control the start-stop and speed of the driving motor 1. After the signal of the torque sensor 3 is collected and processed by the data acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com