Gynecological nursing gauze preparation equipment

A technology of obstetrics and gynecology, gauze, applied in medical science, bandages, etc., can solve the problem of different sizes of gauze, and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

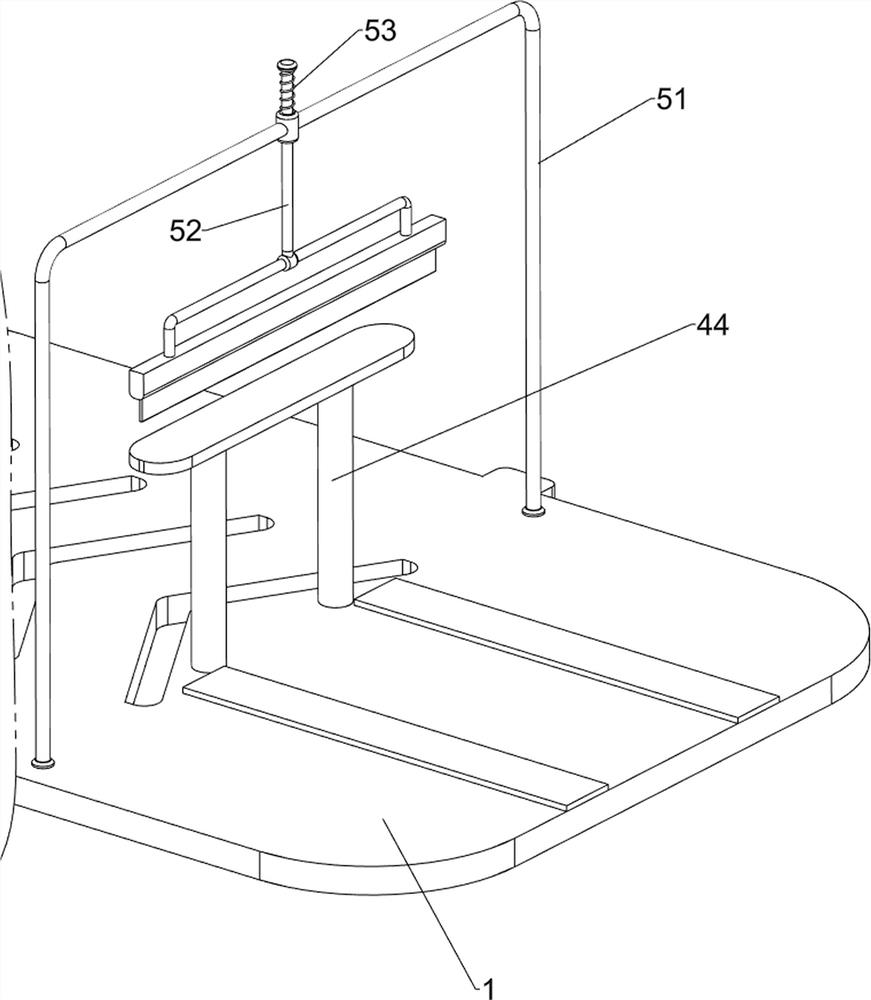

[0031] A kind of obstetrics and gynecology nursing gauze preparation equipment, such as figure 1 , figure 2 , image 3 As shown, it includes a base 1, a collection frame 2, a support column 3, a feeding mechanism 4 and a cutting mechanism 5. The right side of the base 1 is provided with a collection frame 2, and the left side of the base 1 is symmetrically provided with a support column 3. 1 is provided with a feeding mechanism 4 in the middle, and a cutting mechanism 5 is provided on the right side of the base 1.

[0032] First place the gauze on the feeding mechanism 4, then pull the gauze, wait for the gauze to move to a suitable position and then operate the cutting mechanism 5 to realize the cutting of the gauze. After the cutting is completed, no longer pull the gauze, and stop the operation of the cutting mechanism 5 , if you need to cut the gauze again, just repeat the above steps.

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , figure 2 , image 3 As shown, the discharge mechanism 4 includes a placement rod 41, a first pillar 42, a roller 43 and a support plate 44, a placement rod 41 is placed between the two support pillars 3, and a first pillar is arranged symmetrically on the left side of the base 1. 42. A support plate 44 is provided on the right side of the base 1, and a roller 43 is provided on the first pillar 42 to rotate symmetrically up and down.

[0035] First place the gauze on the placement bar 41, then pull one end of the gauze through between the upper and lower rollers 43, place one end of the gauze on the support plate 44, and when the gauze is pulled, the roller 43 will also rotate, so reciprocating, It is convenient for people to pull the gauze, and also cooperates with the cutting of the 5 pairs of gauze by the cutting mechanism.

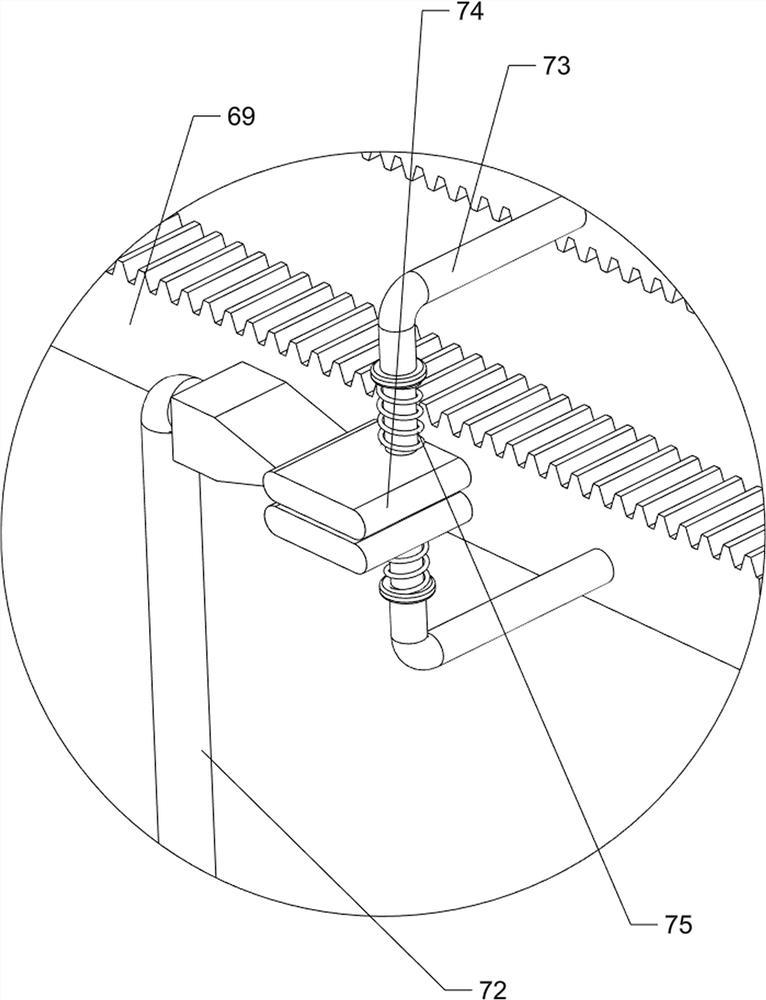

[0036] The cutting mechanism 5 includes an L bar 51, a knife 52 and a first spring 53. The rig...

Embodiment 3

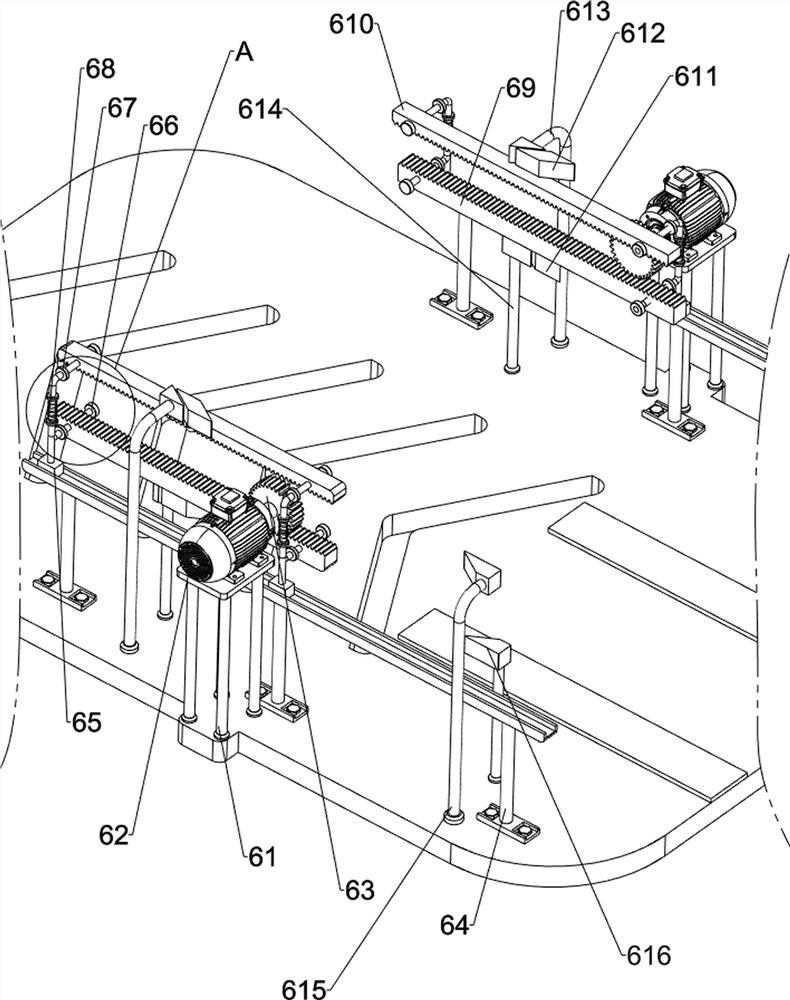

[0039] On the basis of Example 2, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, a moving mechanism 6 is also included. The base 1 is provided with a moving mechanism 6. The moving mechanism 6 includes a mounting plate 61, a motor 62, a first gear 63, a slide rail 64, a slider 65, a moving column 66, and a connecting column. 67, the second spring 68, the lower rack 69, the upper rack 610, the first double-sided wedge 611, the second double-sided wedge 612, the upper wedge 613, the lower wedge 614, the first wedge 615 and the second wedge Two wedge-shaped blocks 616, base 1 is provided with mounting plate 61 symmetrically front and rear, motor 62 is installed on the mounting plate 61, first gear 63 is all provided on the output shaft of motor 62, and slide rail 64 is provided with front and rear symmetry on base 1 , slide rail 64 is equipped with two sliding blocks 65, sliding blocks 65 are equipped with moving columns 66, moving columns 66 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com