Flexible gripper library integrated control system

An integrated control system and gripper technology, applied in the direction of comprehensive factory control, load suspension components, safety devices, etc., can solve the problems of high investment cost, unfavorable rapid switching of multiple models, etc., and achieve the effect of low cost and fast automatic switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

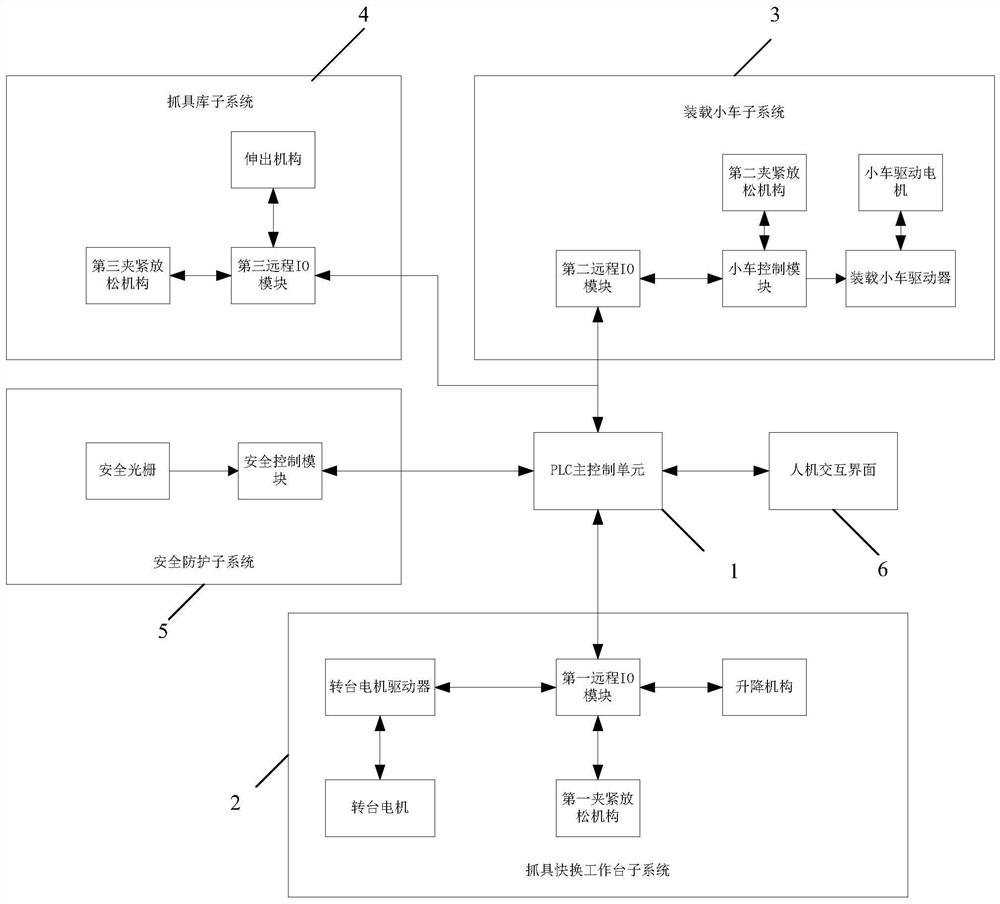

[0015] like figure 1 As shown, in this embodiment, an integrated control system for a flexible gripper library includes a PLC main control unit 1, a gripper quick-change table subsystem 2 and a loading trolley subsystem 3 that are electrically connected to the PLC main control unit 1 respectively. and gripper library subsystem 4.

[0016] In this embodiment, a database is stored in the PLC main control unit 1, and the database is the workpiece model, the gripper required for the workpiece model, the first location information of the gripper in the gripper library subsystem 4, and The corresponding relationship between the gripper and the second location information in the gripper quick-change workbench subsystem 2; the PLC main control unit 1 is used to obtain (for example: obtained from the production management system) the model information of the current workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com